Grinding method of outer circles of high-precision slender casing parts

A high-precision, workpiece-friendly technology, which is applied to machine tools, grinding/polishing equipment, grinding machines, etc. designed for grinding the rotating surface of workpieces, can solve the problem of high geometric accuracy requirements for positioning reference holes, large mandrel input, and accidental workpieces. Looseness and other problems, to achieve the effect of reducing the difficulty and quantity of grinding, reducing processing costs, and eliminating deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

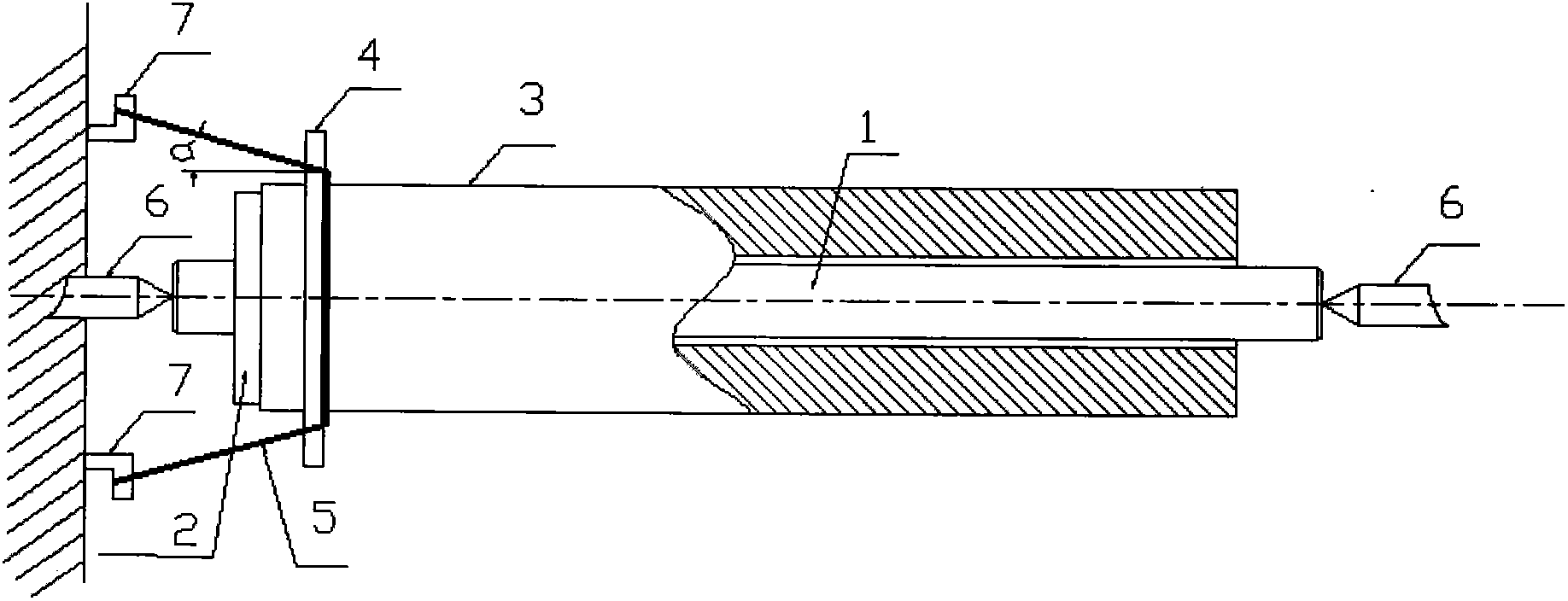

[0033] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0034] Taking a high-precision slender valve sleeve as an example, the material of the workpiece 3 is 440C stainless steel, the length is 287mm, and the diameter of the inner hole is Φ11.01mm. Hole coaxiality 0.02mm.

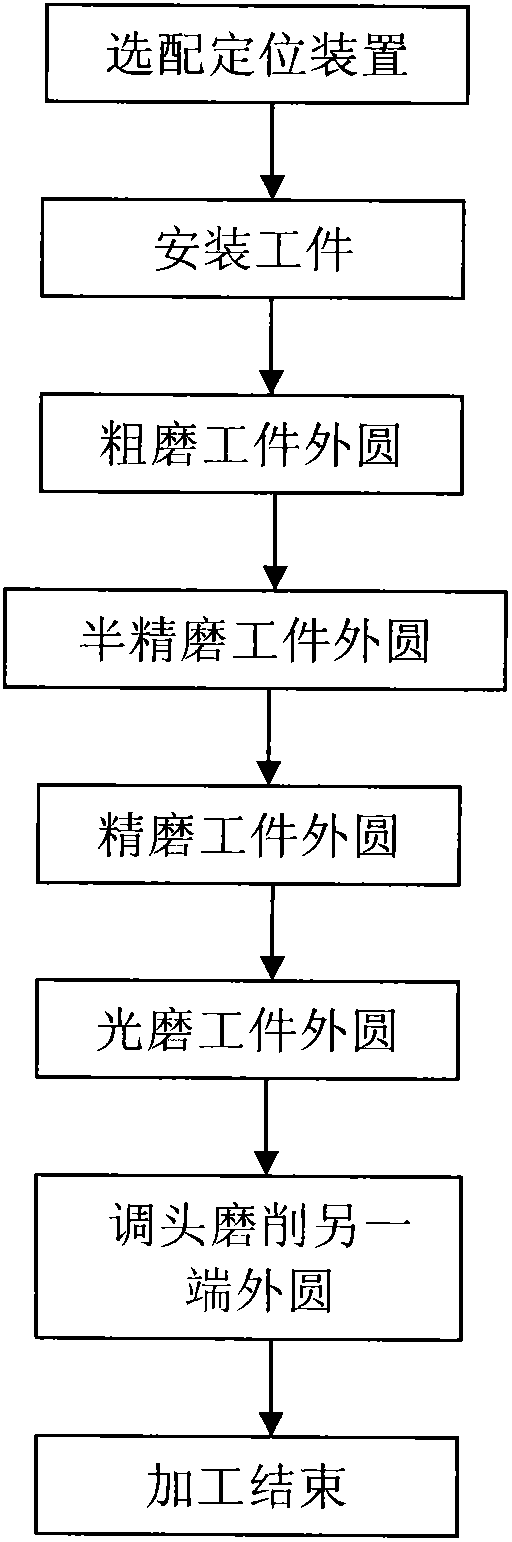

[0035] The processing flow is as follows figure 1 Shown:

[0036] Step 1: Make a positioning device for grinding the outer circle of high-precision slender sleeve workpieces

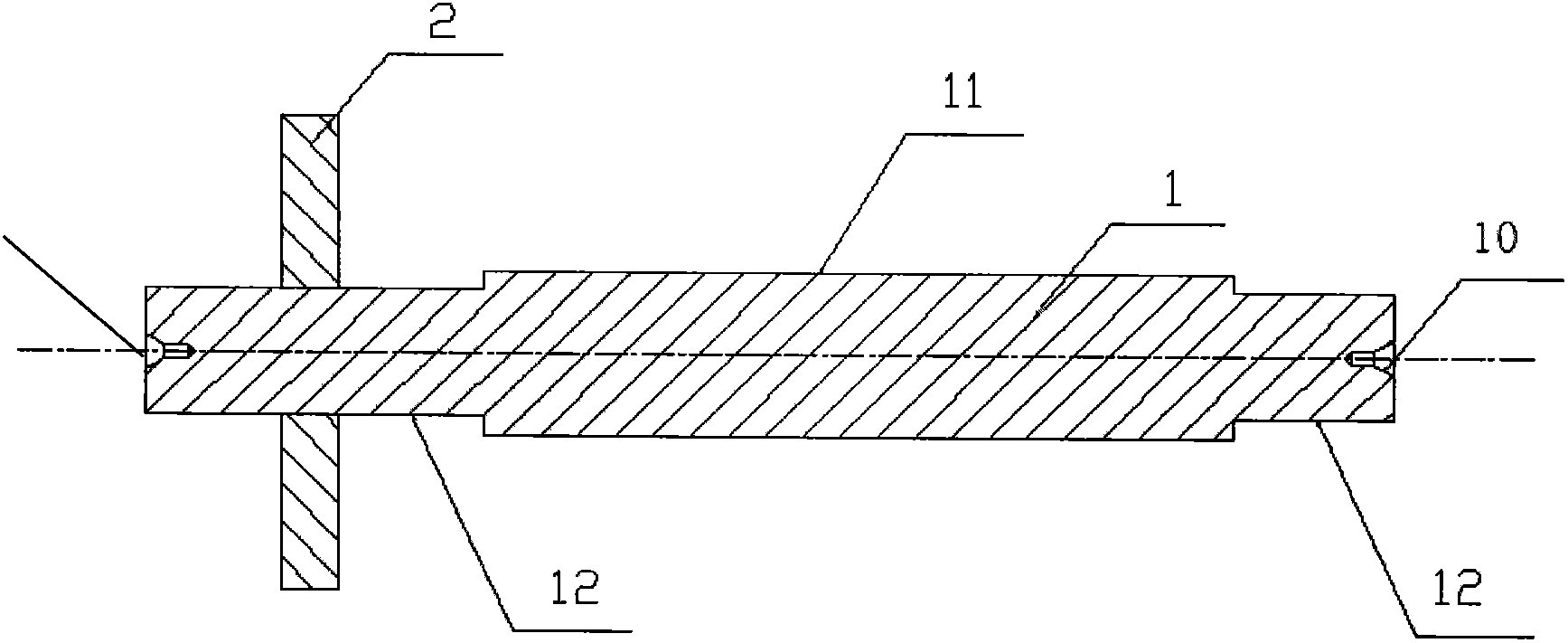

[0037] The positioning device is a cylindrical mandrel 1 with a positioning piece 2. The two ends of the mandrel 1 are processed with a central hole 10. The positioning piece 2 is located at a distance of 15 mm to 20 mm from one end of the mandrel 1. The thickness of the positioning piece 2 is between 3 mm and 7 mm; The outer diameter of the sheet 2 is larger than the inner diameter of the workpiece 3, and its function is to limit the axial serial movement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com