High-performance concrete expansion agent and preparation method thereof

A high-performance concrete and expansion agent technology, applied in the field of cement admixture, can solve the problems of large shrinkage, complex production process, small expansion rate, etc., achieve the effect of small shrinkage in the later stage, overcome the problem of structural leakage, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

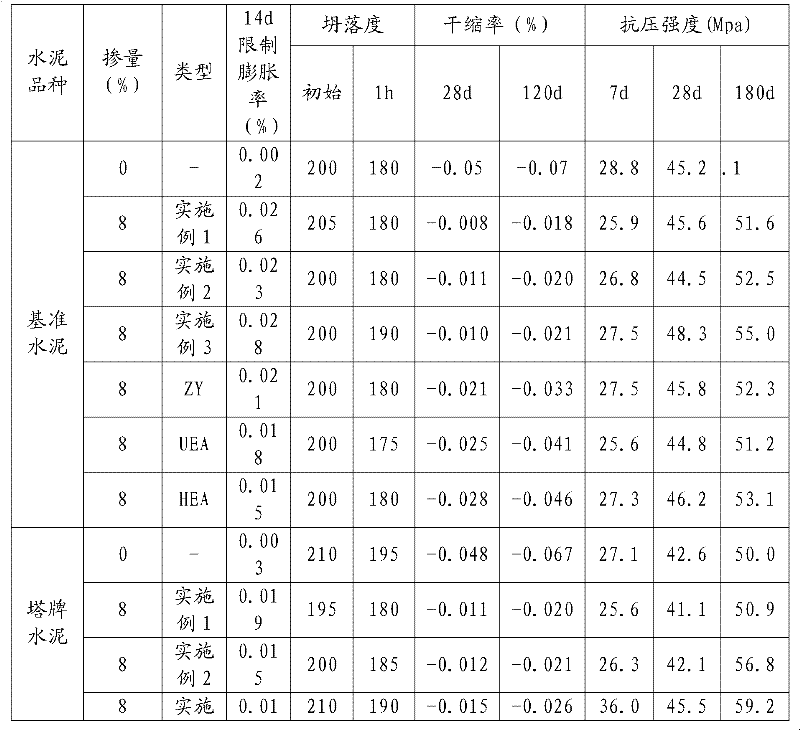

Embodiment 1

[0036] Take by weight percentage the expansion clinker 50% of embodiment A, anhydrite 30% (Wuhan Longyuan, sulfur trioxide content is greater than 50%), calcined metakaolin 20% (Guangdong Yunfu, aluminum oxide content is greater than 20%) , calcination temperature 750-850°C), mix the raw materials and grind until the specific surface area is 260m 2 / kg, 0.08mm square hole sieve remaining 12%; obtained product.

Embodiment 2

[0038] Weigh 50% of the expanded clinker of Example B, 40% of anhydrite, and 10% of the high-alumina clinker (Zunyi, Guizhou, with an aluminum oxide content of 50-55%, and a silicon dioxide content of less than 7%) in Example B by weight percentage. Mix and grind until the specific surface area is 250m 2 / kg, 0.08mm square hole sieve remaining 12%; obtained product.

Embodiment 3

[0040] Take by weight percentage the expansion clinker 70%, anhydrite 20%, calcined diatomite (Zhejiang Lin'an, silicon dioxide content 75-95%, aluminum oxide 3-6%, calcining temperature 850- 1000°C) 10%, mix the raw materials and grind until the specific surface area is 280m 2 / kg, 0.08mm square hole sieve remaining 9%; obtained product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com