Device and method for measuring combustion characteristics of combustible materials

A combustion property and weight sensor technology, applied in the field of fire protection, can solve the problems of high cost, low fire source power, measurement, etc., and achieve the effect of convenient calculation, simple structure and small restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

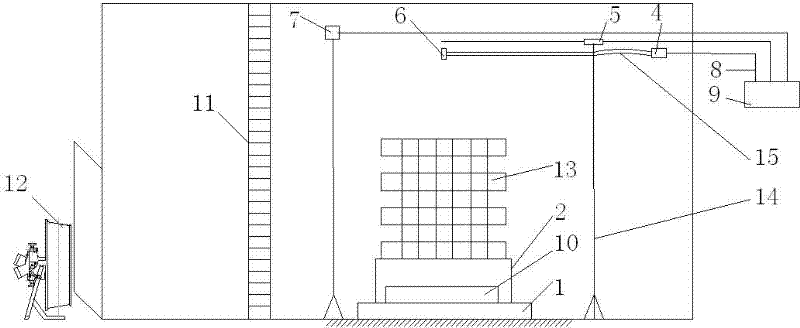

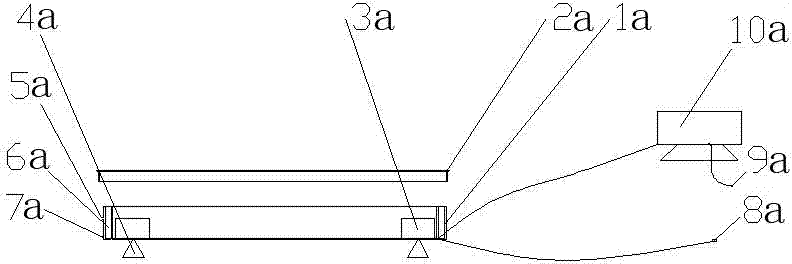

[0045] Example 1: The oil pan (containing 50L diesel oil) is placed on the high-temperature-resistant support 2, and the high-temperature-resistant support 2 is placed on the high-temperature-resistant floor scale 1. The bolometer is 0.5 m away from the oil pan in the horizontal direction, and the thermoelectric Couple 5 and bidirectional probe 6 are fixed 1 m directly above the oil pan through brackets. The bolometer, the thermocouple 5, the bidirectional probe 6, and the high temperature floor scale 1 transmit the data to the data acquisition system through the compensation wire 8.

[0046] When measuring, first start the data acquisition system, ignite the diesel oil, measure the quality change, temperature change, heat radiation amount change and fire plume flow pressure of the diesel oil over time, and obtain the combustion rate of the combustibles according to the measurement results kg / s, and then use the oxygen bomb calorimeter to measure the calorific value of the c...

Embodiment 2

[0054] To measure the influence of fire source power under windy conditions, the specific implementation method is as follows:

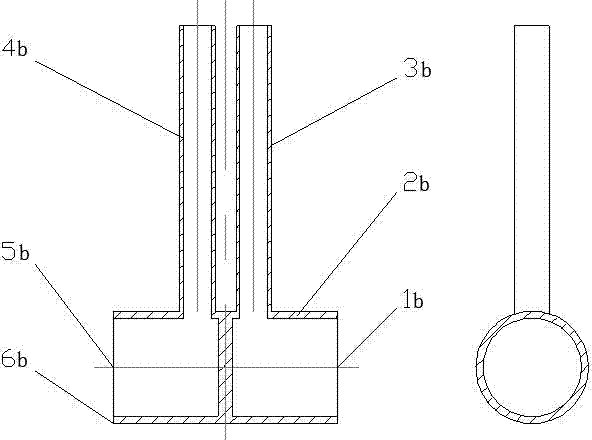

[0055] The wooden stack is placed on the high-temperature-resistant bracket, the high-temperature-resistant bracket is placed on the floor scale, the constant power ignition plate is placed directly under the wooden stack, and is located on the floor scale. The heat radiation meter is 0.5 meters away from the oil pan in the horizontal direction. The two-way probe 6 is fixed 1 meter directly above the oil pan through a bracket. The rectification grid is 1 meter away from the edge of the wood stack in the horizontal direction, and the blower is located behind the rectification grid and behind the opened door. The bolometer, thermocouple, and weighbridge transmit the data to the data acquisition system through the compensation wire. The bidirectional probe 6 is connected to the micromanometer through the trachea, and the micromanometer transmits the da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Thermal power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com