Array substrate, liquid crystal display device as well as manufacturing and repairing method of array substrate

An array substrate and liquid crystal display technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as electrostatic breakdown of parasitic capacitance and difficult repair, and achieve the effects of improved reliability, easy repair, and flexible setting positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

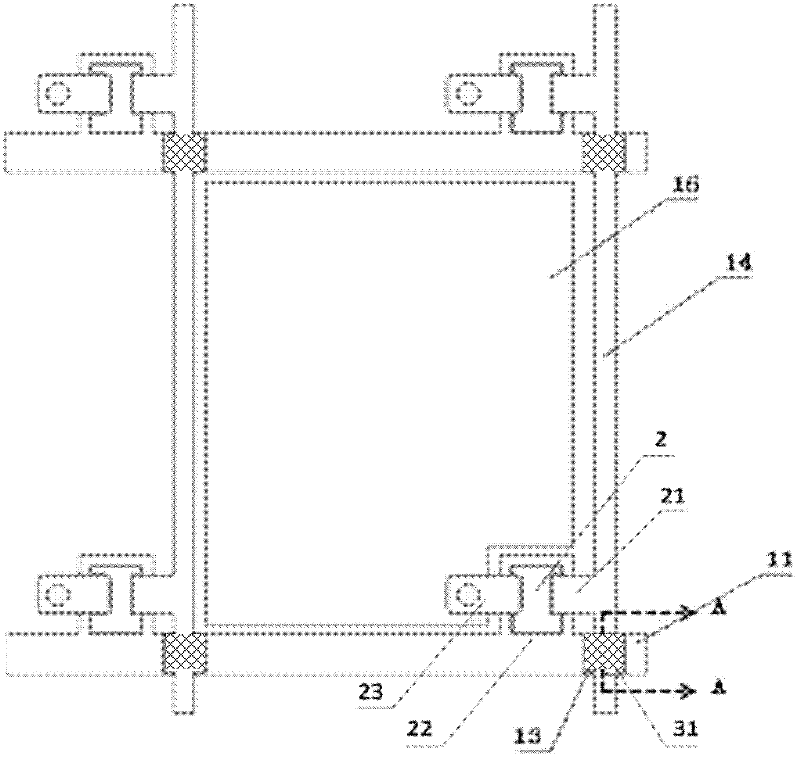

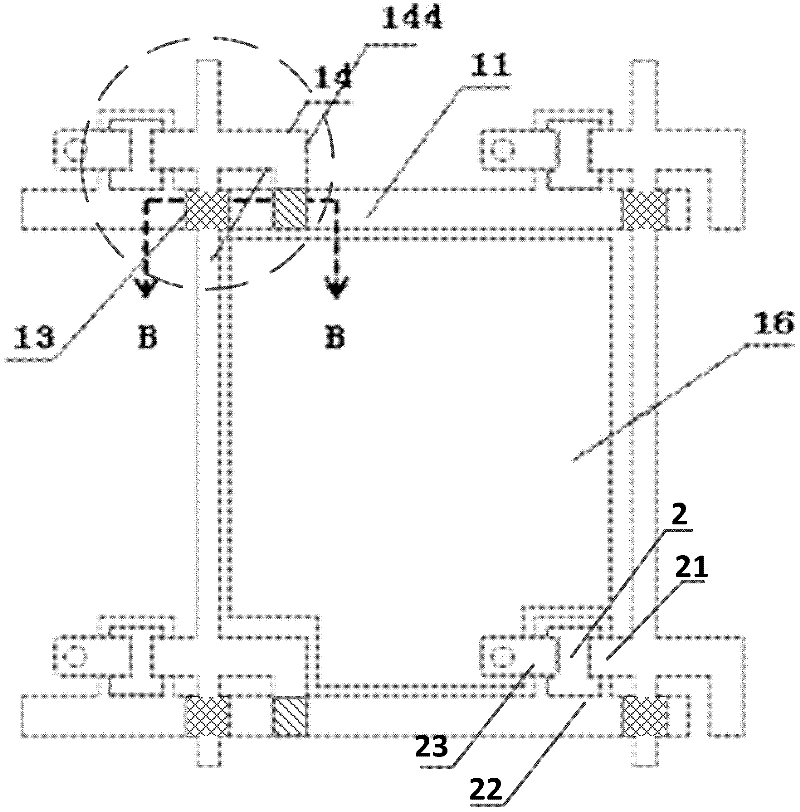

[0033] Embodiment 1, the implementation mode of the thin film transistor liquid crystal display array substrate manufactured based on the five-time mask process of the liquid crystal display device: as Figure 4~6 As shown, the data line of the source electrode 21 of the thin film crystal 2 is extended outward to form a branch portion 144, and the branch portion 144 is bent towards the adjacent gate line 11 until it overlaps with the gate line 11. The overlapping area forms the The protection capacitor 32, that is, the protection capacitor 32 and the parasitic capacitor 31 are formed on the same gate line. Since one end of the parasitic capacitor 31 shares a gate line 11 with the protection capacitor 32, and the other end of the parasitic capacitor 31 communicates with the source 21, that is, communicates with the branch portion 144, the parasitic capacitor 31 and the protection capacitor 32 are electrically connected in parallel. .

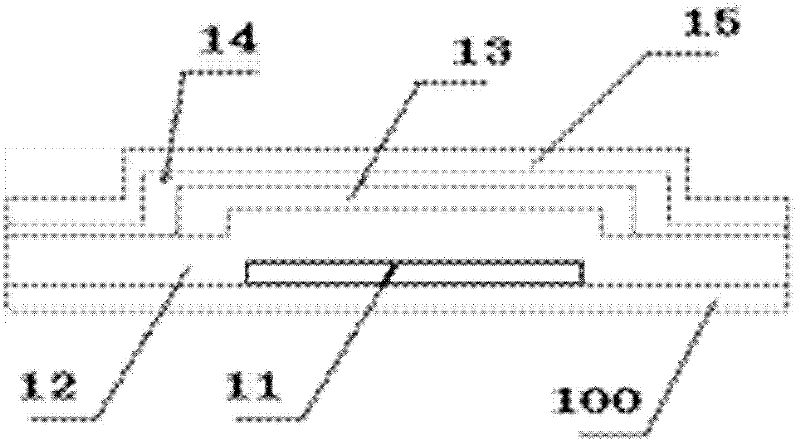

[0034] like Figure 5 As shown, the arra...

Embodiment 2

[0046] Embodiment 2, the implementation mode of the thin film transistor liquid crystal display array substrate manufactured based on the four masking process of the liquid crystal display device: as Figure 4 As shown, the data line of the source electrode 21 of the thin film crystal 2 is extended outward to form a branch portion 144, and the branch portion 144 is bent towards the adjacent gate line 11 until it overlaps with the gate line 11. The overlapping area forms the The protection capacitor 32, that is, the protection capacitor 32 and the parasitic capacitor 31 are formed on the same gate line. Since one end of the parasitic capacitor 31 shares a gate line 11 with the protection capacitor 32, and the other end of the parasitic capacitor 31 communicates with the source 21, that is, communicates with the branch portion 144, the parasitic capacitor 31 and the protection capacitor 32 are electrically connected in parallel. .

[0047] like Figure 7 As shown, the array su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com