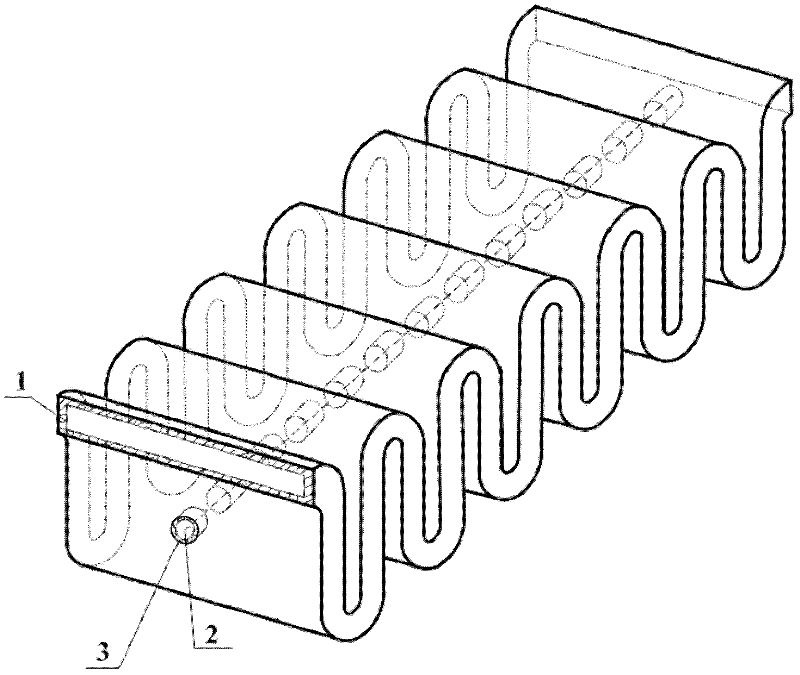

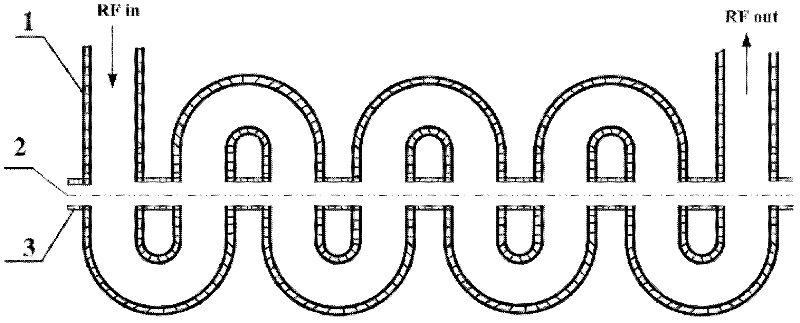

Gradient ridge loading tortuous waveguide slow wave line

A meandering waveguide and meandering slow wave technology, applied in the field of traveling wave tube amplifiers, can solve the problems of no impedance matching, large reflection oscillation, uneven propagation path, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

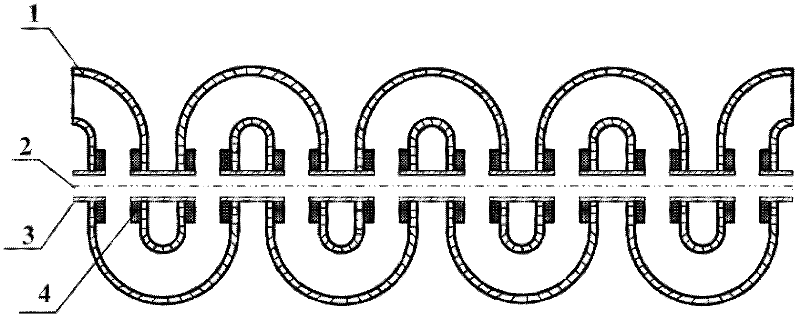

Embodiment Construction

[0027] Such as Figure 7 with Figure 8 , in the 3mm wave band, the structural dimensions of the specific scheme of loading the meandering waveguide slow wave line with the linear gradient ridge are as follows: (unit: mm) a=2, b=0.3, H=0.6, L=1.542, r 0 =0.2, w=2, d=0.07, h 1 =0.42, h 2=0.09, h=H=0.6. Use three-dimensional electromagnetic simulation software to simulate the slow-wave structure of the gradient ridge loading meander waveguide provided by the present invention, obtain its dispersion characteristics, coupling impedance, standing wave coefficient and high-frequency loss, and have the same ridge width w, the same ridge overall height h is compared with the ridge-loaded meander waveguide slow-wave structure with the same ridge thickness d. The three-dimensional electromagnetic simulation software is used to simulate the two slow wave structures for 40 cycles respectively, and obtain the standing wave coefficient and S parameter of the two structures. Simulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com