Method for pre-polishing polishing pad by adopting polysilicon CMP (Chemical Mechanical Polishing) process

A chemical mechanical and pre-grinding technology, which is applied in the direction of grinding devices, grinding machine tools, manufacturing tools, etc., can solve the problems of high production cost, difficulty in reaching the chemical equilibrium state of new grinding pads, and long time required for Poly film production, so as to save time and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A kind of specific implementation method of the technical solution of the present invention is provided below in conjunction with accompanying drawing of description,

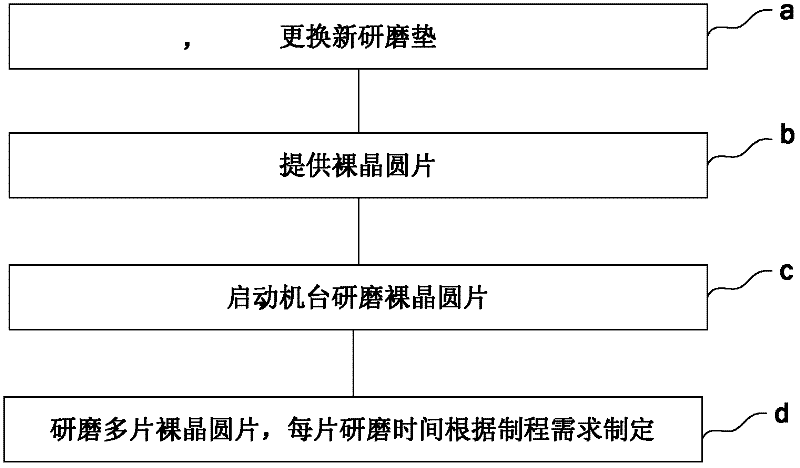

[0017] Step a, replace the new grinding pad;

[0018] Step b, providing a bare silicon wafer;

[0019] Step c. Start the machine to grind the bare silicon wafer;

[0020] Step d, grinding multiple bare silicon wafers, the grinding time of each piece is determined according to the process requirements)

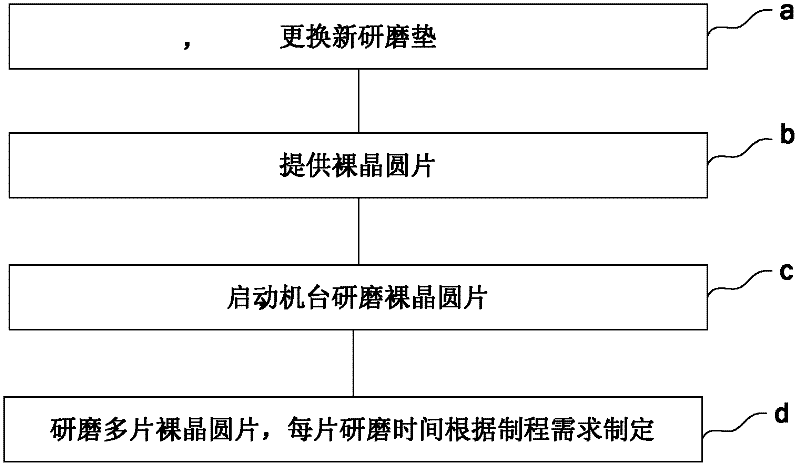

[0021] In addition, another embodiment provided by the present invention includes the following steps:

[0022] Provide multiple bare silicon wafers;

[0023] Place the wafer boat or wafer boat box (cassette or Pod) containing the bare silicon wafer on the standard mechanical interface (SMIF) of the grinding machine;

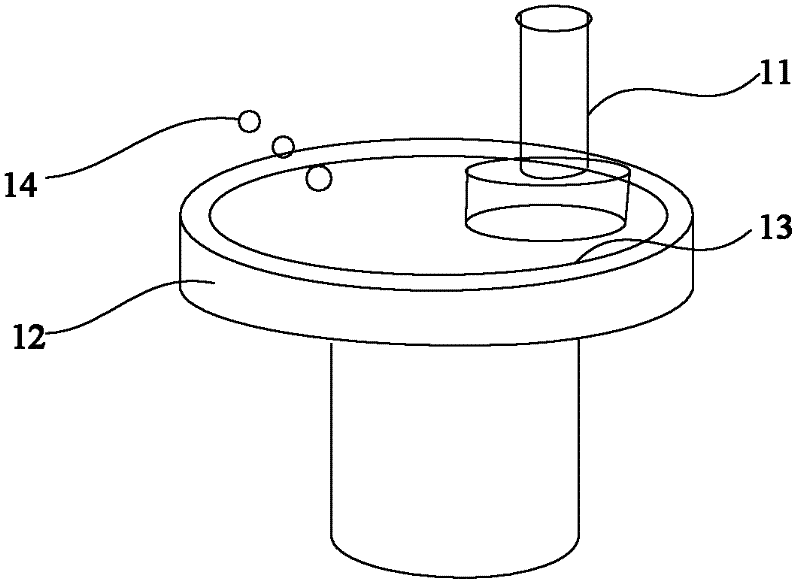

[0024] Fix the grinding pad on the grinding mechanical platform, and when the grinding mechanical platform rotates, the grinding pad will rotate synchronously;

[0025] Start the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com