Basic flux-cored wire for bridge steel

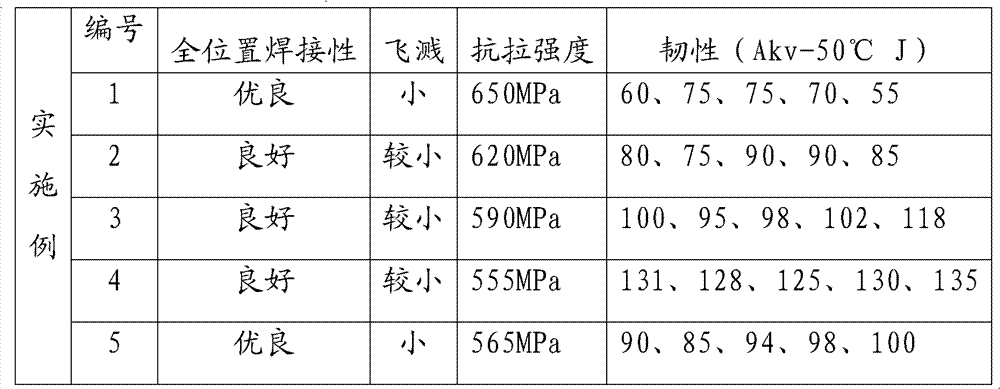

A flux-cored welding wire, alkaline technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of low weld strength and low-temperature impact toughness, inability to realize all-position welding, large spatter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

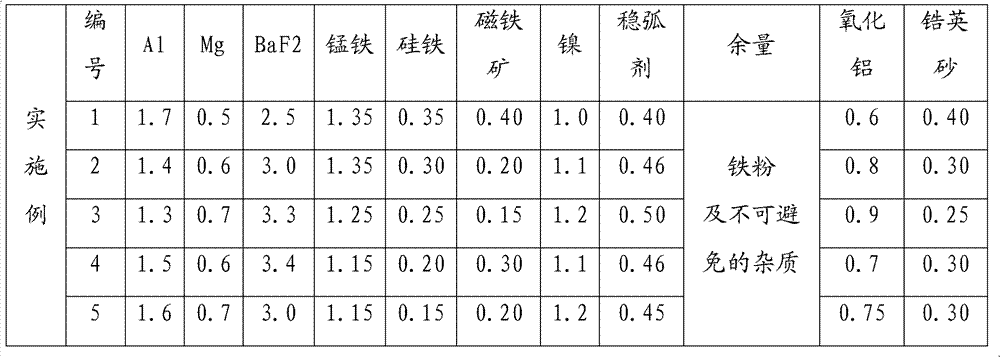

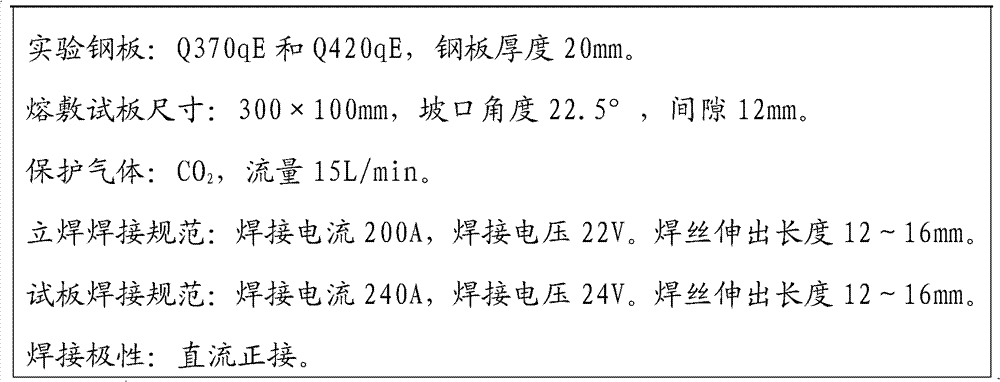

[0027] Below in conjunction with specific embodiment the present invention is described in further detail:

[0028] A basic flux-cored welding wire for bridge steel of the present invention comprises a carbon steel sheath and a wrapped flux core, the proportions of each component in the flux core to the total weight of the weld wire are: 1.3% to 1.7% of aluminum and 0.5% of magnesium ~0.6%, barium fluoride 2.5%~3.4%, ferromanganese 1.15%~1.35%, ferrosilicon 0.15%~0.35%, magnetite 0.15%~0.40%, nickel 1.0%~1.2%, arc stabilizer 0.4% ~0.5%, alumina 0.6%~0.9%, zircon sand 0.25%~0.4%, the rest is iron powder and unavoidable impurities, wherein the arc stabilizer is composed of potassium titanate, magnesia, cryolite and sodium water The glass powder is mixed according to the weight ratio of 2:2:4:2.

[0029] The arc stabilizing agent is baked at a high temperature of 750°C and kept warm for 2 hours, and then the material obtained by smelting is reprocessed into powder, and the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com