An assembly welding process method of elastic oil tank with connecting pipe structure

A technology of elastic fuel tank and process method, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems affecting the verticality of elastic fuel tank, the difference in size, the influence of the size of the unevenness of the chassis, etc., to achieve both economy and practicability , Solve the effect of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

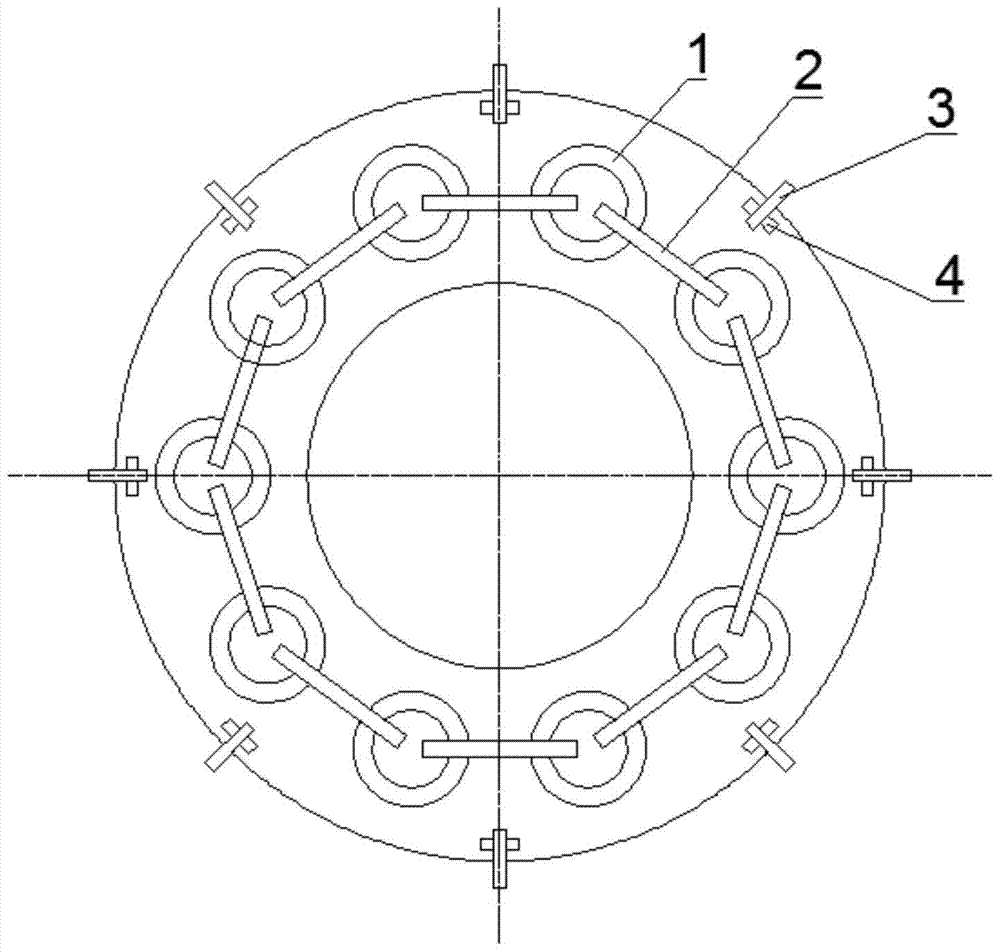

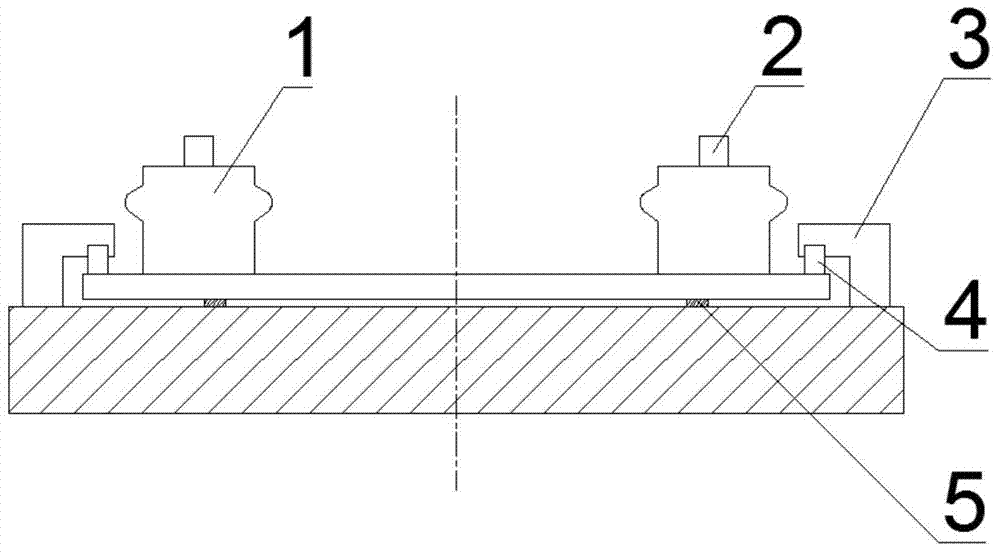

[0024] The object of the present invention is to provide an assembly process method of the chassis of the elastic fuel tank with connecting pipes which ensures the size of the product after the chassis of the flexible fuel tank is welded. Technical scheme of the present invention is:

[0025] (1) Chassis blanking processing: The chassis material is made of ordinary carbon structural steel plate Q235 or low-alloy structural steel Q345. After blanking, it is flattened and processed so that the flatness of the chassis is not greater than 0.05mm; (2) According to the requirements of the drawing, forging, Casting and processing methods to manufacture elastic oil tank 1, support iron and ring; (3) Assemble elastic oil tank 1, support iron and ring according to the requirements of the drawing, and weld the support iron and the weld seam of the elastic oil tank; (4) According to the requirements of the drawing, assemble Elastic oil tank 1. The connecting pipe and the chassis are tight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com