Method for manufacturing titanium sponge packing barrel body

A production method and technology for packaging barrels, which are used in packaging, transportation, packaging, containers, etc., can solve problems such as substandard environmental discharge and inability to build factories, and achieve the effects of meeting environmental protection requirements, ensuring product quality, and improving transportation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

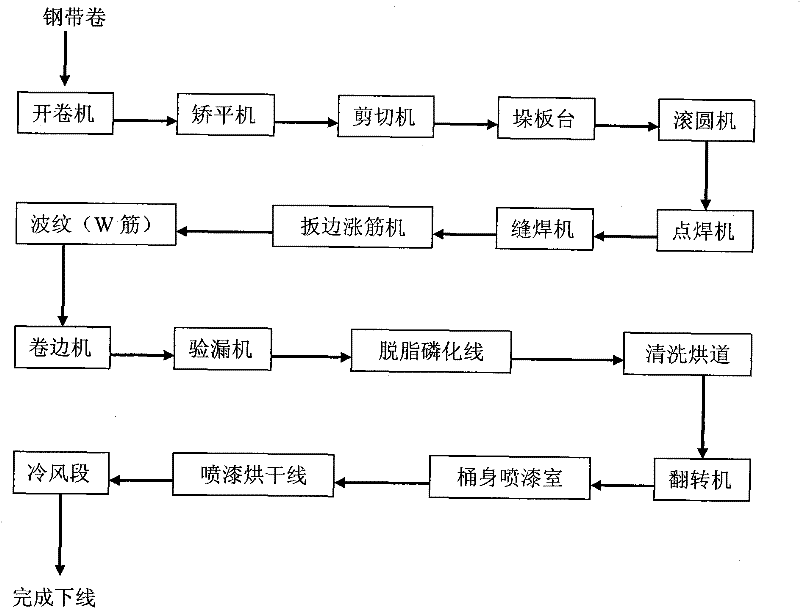

[0012] Such as figure 1 As shown, the manufacturing method of the 200L sponge titanium packaging drum body of the present invention includes the following steps: firstly place the steel strip coil for barrel making on the uncoiler to uncoil, level it with a leveler, and cut it into a size that meets the specifications through a shearing machine. The steel plate; the shearing machine cuts the steel plate that meets the specifications and stacks it on the stacking platform, then passes the steel plate through the rounding machine, rolls it into a cylinder that meets the size, and then welds it with a spot welding machine and a seam welding machine; through Ribbon stretching machine, corrugation machine, and crimping machine process the barrel body, and the leak teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com