Liquid crystal aligning agent, liquid crystal aligning film prepared by using same and liquid crystal display element prepared by using liquid crystal aligning agent

A liquid crystal alignment agent and liquid crystal alignment technology, applied in liquid crystal materials, optics, instruments, etc., can solve problems such as poor quality and yield, inability to effectively solve afterimages, poor stability of pretilt angle over time, etc., to achieve Effect of good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0094] The present invention will be further described with reference to the following examples, but it should be understood that the examples are for illustrative purposes only and should not be construed as limitations on the implementation of the present invention.

[0095] C7CDA used in the following examples was prepared according to the method disclosed in Japanese Patent Application Laid-Open No. 2003-96034, and B CDA was prepared according to the method disclosed in Japanese Patent Application Publication No. 2002-162630.

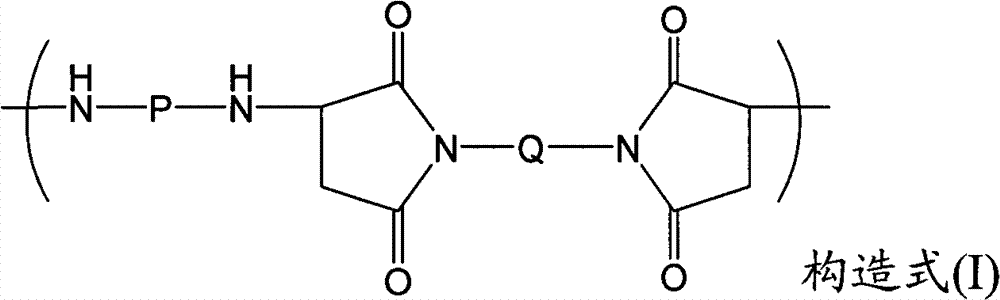

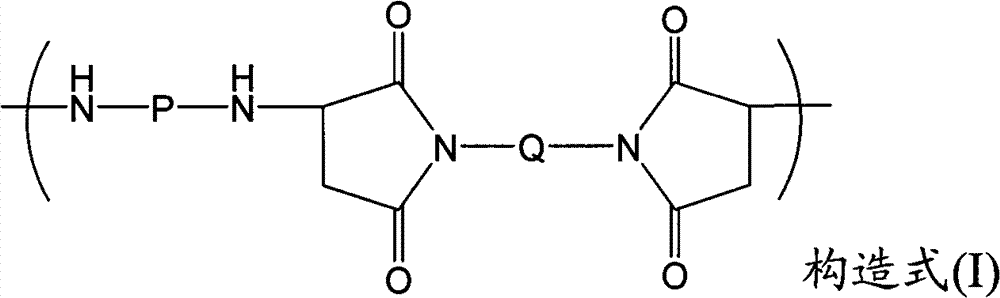

[0096] [Synthetic polymer (A)]

Synthetic example 1

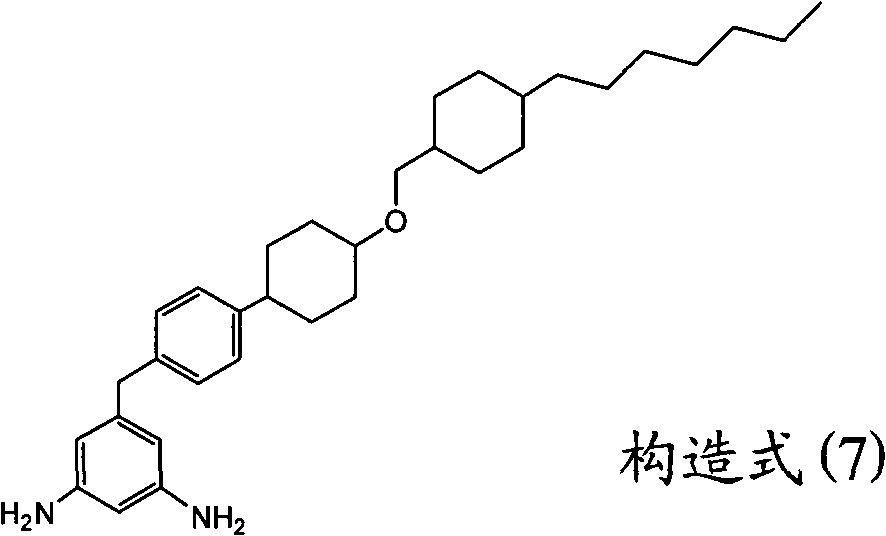

[0098] Set nitrogen inlet, stirrer, heater, condenser and thermometer on a four-necked conical flask with a capacity of 500 ml, and introduce nitrogen, add the first batch of feed including: N, N'-4,4'-diphenyl Dimethyl methane bismaleimide (hereinafter referred to as DPM-BMI) 8.96g (0.025mole), and solvent N-methyl-2-pyrolidone (hereinafter referred to as NMP) 50g, at room temperature (23 ℃ -25 ℃ ) and stirred until dissolved. Then add the second batch of feed and include: p-phenylenediamine (hereinafter referred to as PDA) 2.57g (0.02375mole), compound (hereinafter referred to as C7CDA) 0.61g (0.00125mole) shown in structural formula (7), glacial acetic acid 5g , and NMP 27g, reacted at 100°C for 24 hours, after the reaction, the resulting reaction solution was poured into 1500ml of methanol to precipitate the polymer, and then filtered the resulting polymer and put it into a vacuum oven. After drying at a temperature of 60° C., the polymer (A-1-1) can be obtained.

Synthetic example 2

[0100] Set nitrogen inlet, stirrer, heater, condenser and thermometer on a four-necked conical flask with a volume of 500 ml, and introduce nitrogen, add the first batch of feed including: N, N'-m-phenylene dihydrogen 6.71 g (0.025 mole) of imide (hereinafter referred to as P-BMI) and 50 g of solvent NMP were stirred at room temperature until dissolved. Add the second batch of feed and include: 4,4'-diaminodiphenylmethane (hereinafter referred to as DDM) 3.97g (0.02mole), the compound (hereinafter referred to as BCDA) shown in structural formula (6) 2.26g (0.005 mole), 5 g of glacial acetic acid, and 27 g of NMP were reacted at 100° C. for 24 hours. After the reaction, the reaction solution obtained was poured into 1500 ml of methanol to precipitate the polymer, and the polymer obtained was filtered and placed put into a vacuum oven and dry at a temperature of 60°C to obtain the polymer (A-1-2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com