Composite liquid absorption core of heat dissipation heat pipe and manufacture method thereof

A liquid-absorbing core and heat pipe technology, which is applied in the field of heat pipes for heat transfer, can solve the problems of small backflow resistance, high capillary pressure, and low thermal resistance, and achieve the effects of small heat dissipation space, high capillary pressure, and small thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for manufacturing a heat pipe composite liquid-absorbent core for heat dissipation, comprising the following steps and process conditions:

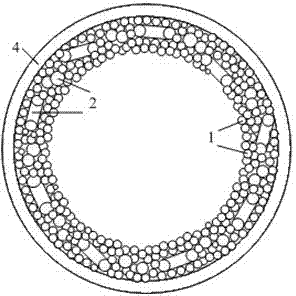

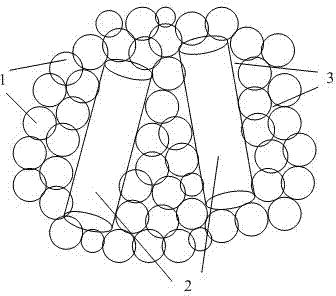

[0039] (1) Take red copper powder particles with a particle size of 100-140 mesh. The red copper powder particles are spherical copper powder and irregular copper powder, with irregular copper powder particles being the majority. Take copper fibers with a diameter of 150 μm and a length of 2 mm, and the mass ratio of copper powder particles to copper fibers is 10:1; put a mandrel in a copper round tube to form a ring-shaped liquid-absorbing core filling space, and fill in copper powder particles and copper fibers. A mixture of fibers; for the filling of copper powder particles mixed with copper fibers, the concentricity of the mandrel and the copper tube must be ensured. If the mandrel is not in the center of the copper tube, the liquid-absorbing core after sintering will be eccentric, which will affect The heat transfer p...

Embodiment 2

[0048] A method for manufacturing a heat pipe composite liquid-absorbent core for heat dissipation, comprising the following steps and process conditions:

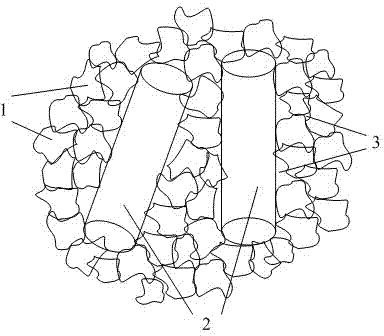

[0049] (1) Take spherical copper powder with a particle size of 140 mesh to 200 mesh, copper fiber diameter of 150 μm, length of 5mm, mass ratio of red copper powder to red copper fiber is 6:1; in a thin red copper flat rectangle of 55mm×55mm×4mm Fill the cavity with a mixture of 5g of copper powder particles and copper fibers; for the filling of copper powder particles mixed with copper fibers, the uniformity of the copper fibers in the copper powder particles must be ensured so that the structure of the liquid-absorbing core is uniform and the micro heat pipe Stable performance.

[0050] (2) Use the mold to flatten the mixture of copper powder and copper fiber in the rectangular cavity, place the thin copper plate rectangular cavity filled with powder on the support and fix it, and place it in a vacuum protection sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com