Divided mask frame assembly and manufacturing method of divided mask frame assembly

A manufacturing method and mask technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as inability to install magnets, magnetic field disconnection, and drastic changes in cross-sectional area, so as to prevent shadowing and masking. die sag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Hereinafter, the structures and functions of the embodiments of the present invention will be described in detail with reference to the accompanying drawings. In describing the present invention, when it is judged that a specific description of a related known function or structure unnecessarily affects the gist of the present invention, the detailed description is omitted.

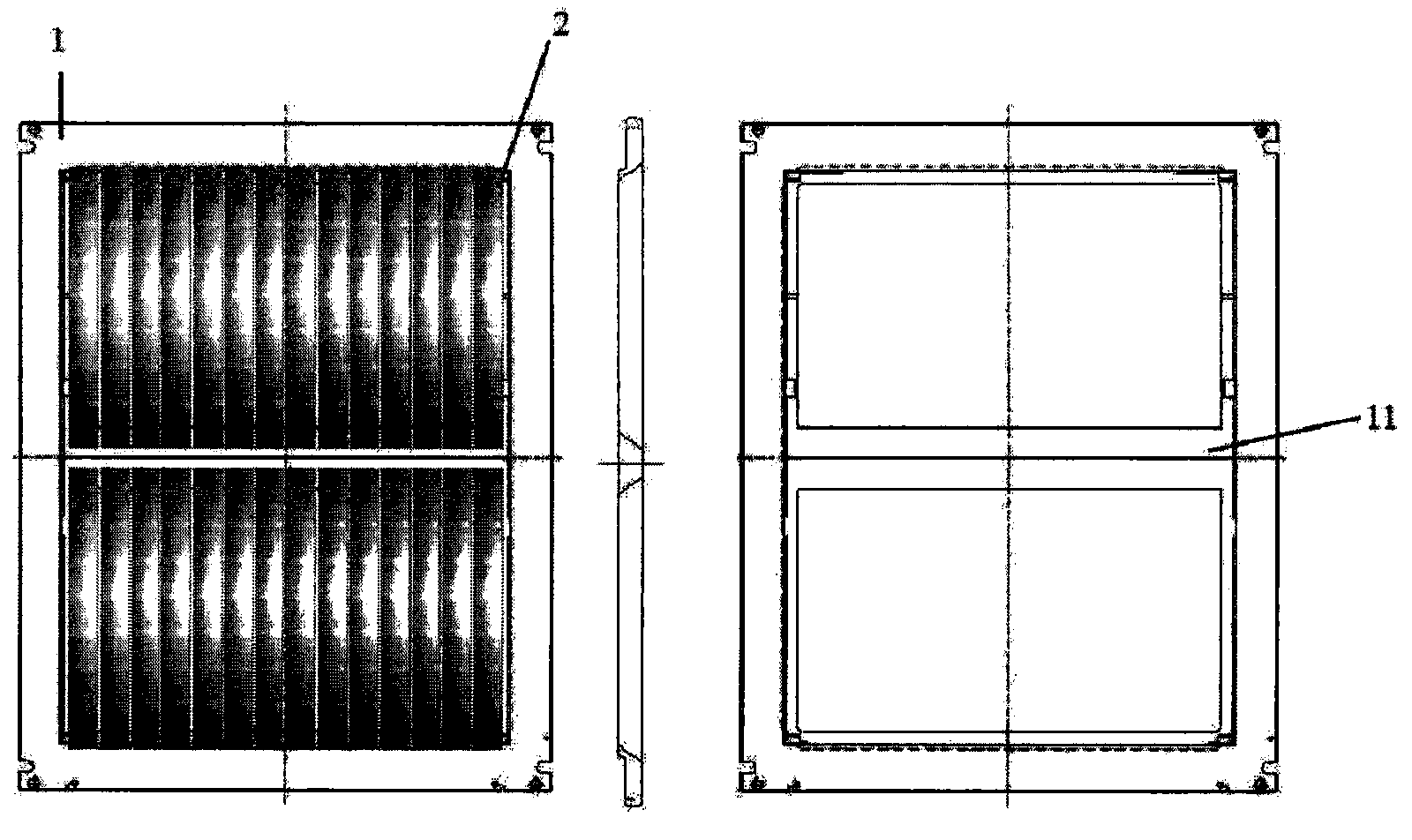

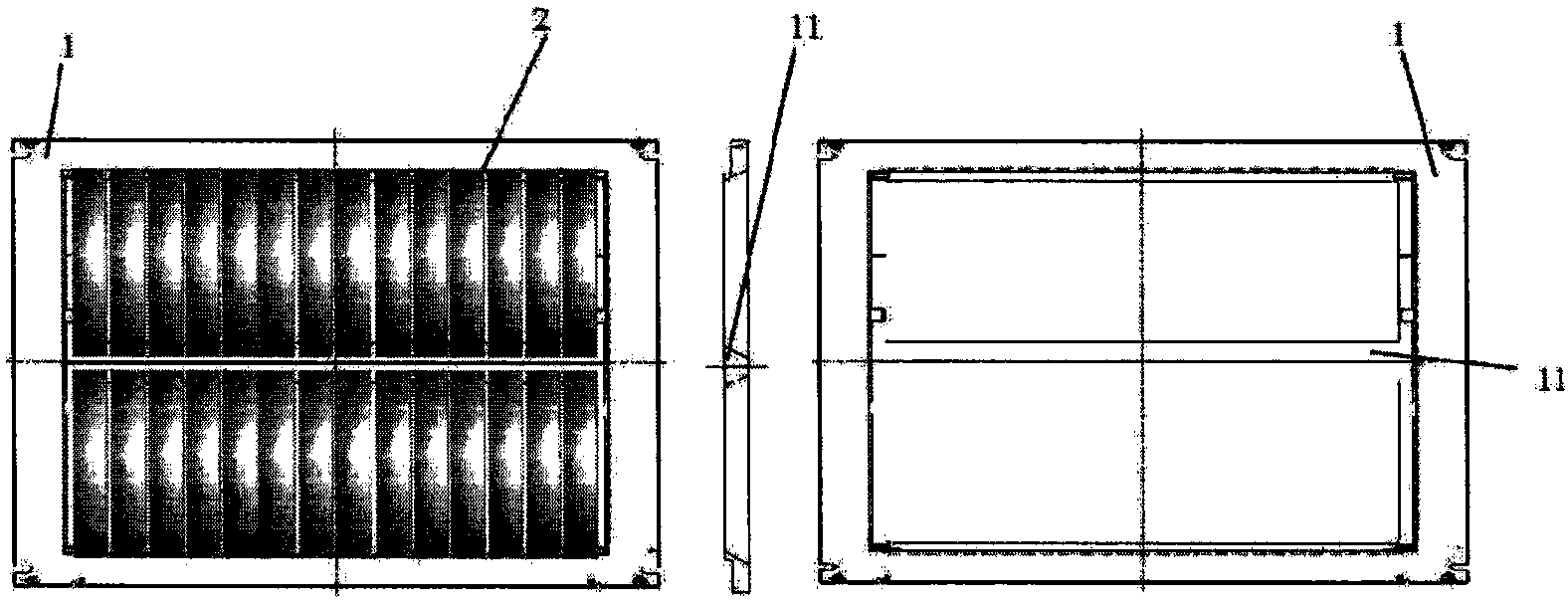

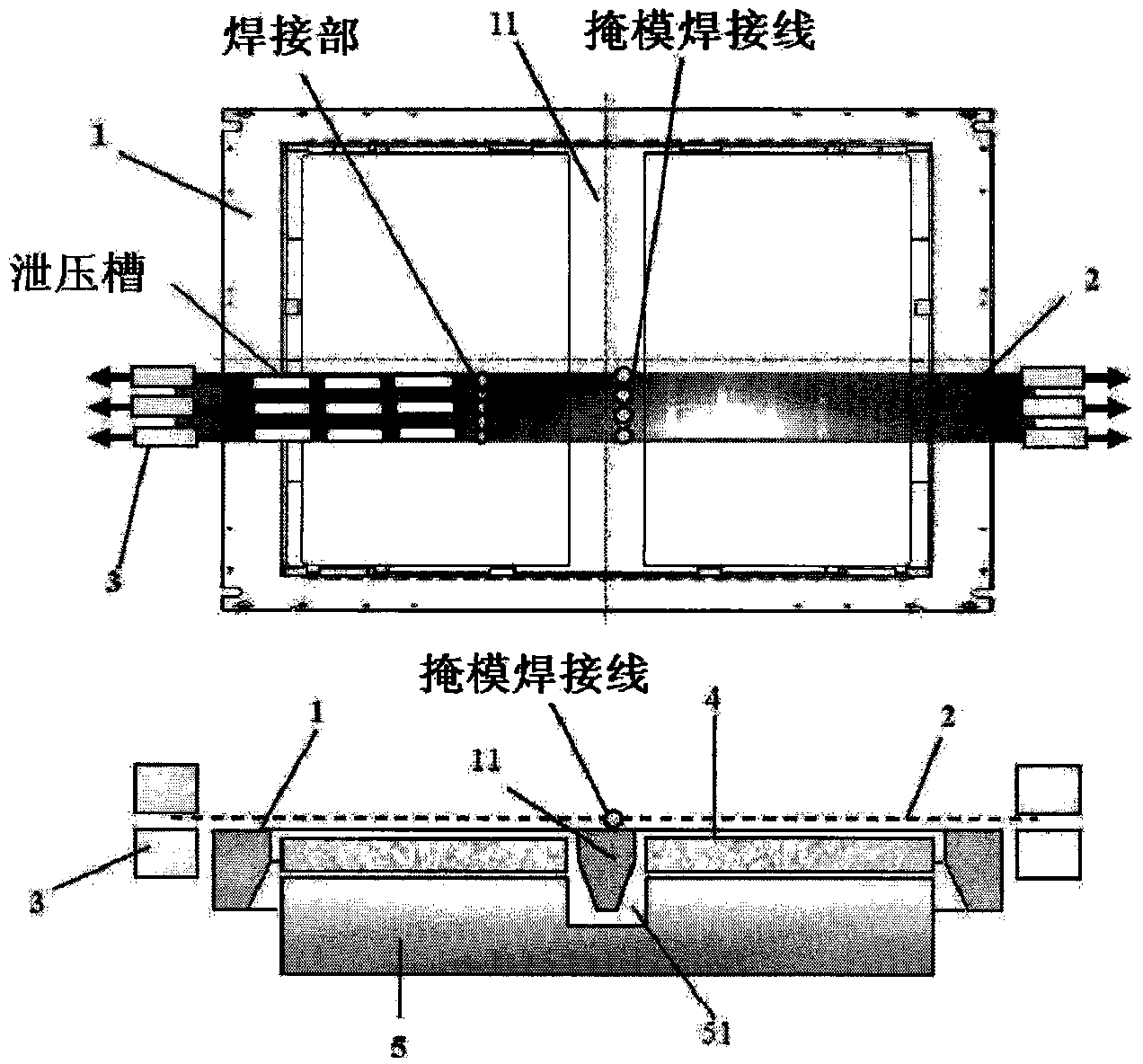

[0085] figure 1 is an illustration showing a mask frame assembly in one embodiment of the present invention, figure 2 is an illustration showing a mask frame assembly in another embodiment of the present invention. As shown in the figure, the mask frame assembly in the present invention has the following structure, forming a rib across the center of the frame (1) to divide the area of the split mask (2) welded on the frame (1) into two , and the respective division masks are welded on the frame (1) and the ribs in the space regions on both sides divided by the ribs. In addition, when solderi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com