Preparation method of fly ash superbead magnetic composite material surface imprinting adsorbent

A technology of magnetic composite materials and fly ash microbeads, which is applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., to achieve the effects of non-destructive, high mechanical strength, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

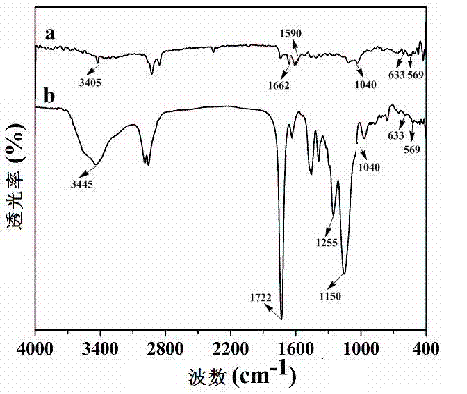

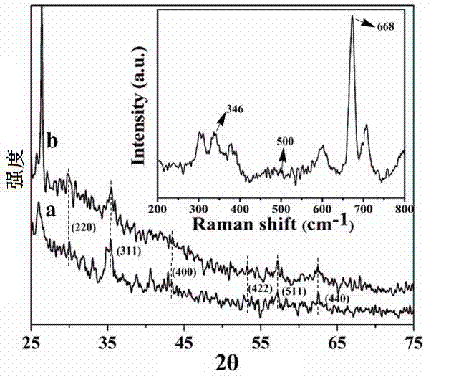

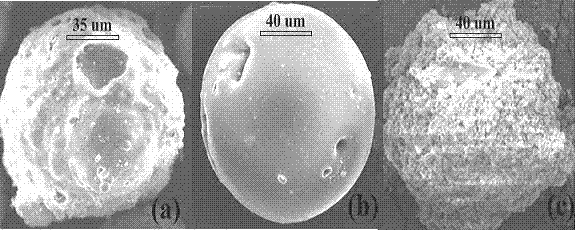

[0031] (1) Amino and aldehyde modification of fly ash

[0032] The fly ash microbeads are treated by acidification, roasting, etc. to obtain activated floating beads; according to the ratio of 3.0g fly ash per 100ml of toluene, the activated fly ash is dispersed in toluene, and the proportion of 1.0ml per gram of fly ash is Add 3-aminopropyltriethoxysilane proportionally, stir and react at 70°C for 12h, then wash the product with absolute ethanol and deionized water, and dry it under vacuum at 60°C. According to the ratio of adding 10ml of phosphate buffer solution (pH=7.0) and 2.0ml of glutaraldehyde (25%, v / v) per gram of aminated fly ash, soak the dried aminated fly ash in the above mixed solution , After reacting for 6.0 h, the product was washed with deionized water and dried under vacuum at 60°C.

[0033] (2) Preparation of Magnetic Fly Ash Microbeads Composite

[0034] Weigh chitosan according to the ratio of 2.0 / 100 (g / ml) and disperse it in 0.1mol / L acetic acid, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com