Preparation method and application of GO/PVDF (Graphene Oxide/Polyvinylidene Fluoride) molecularly imprinted composite membrane

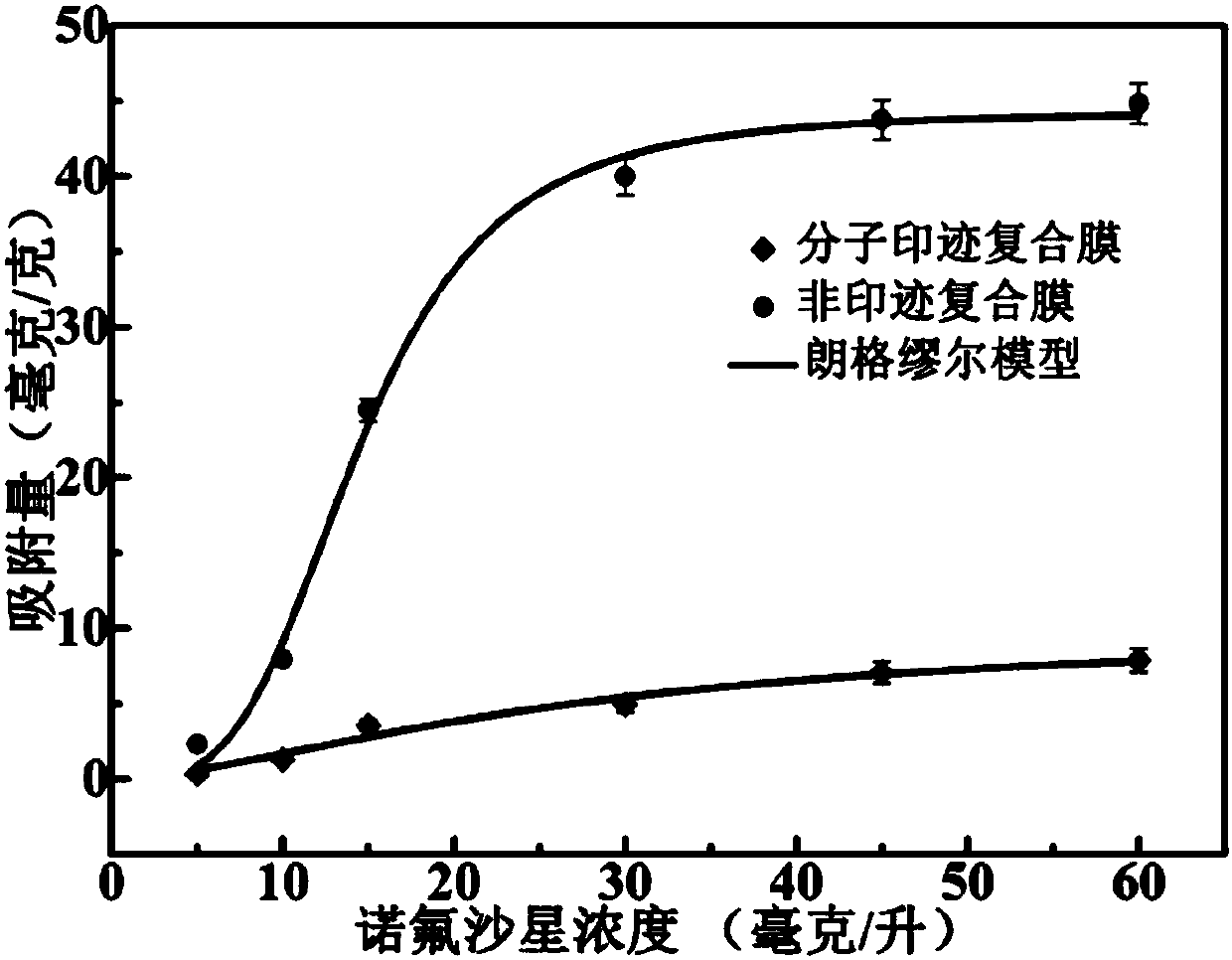

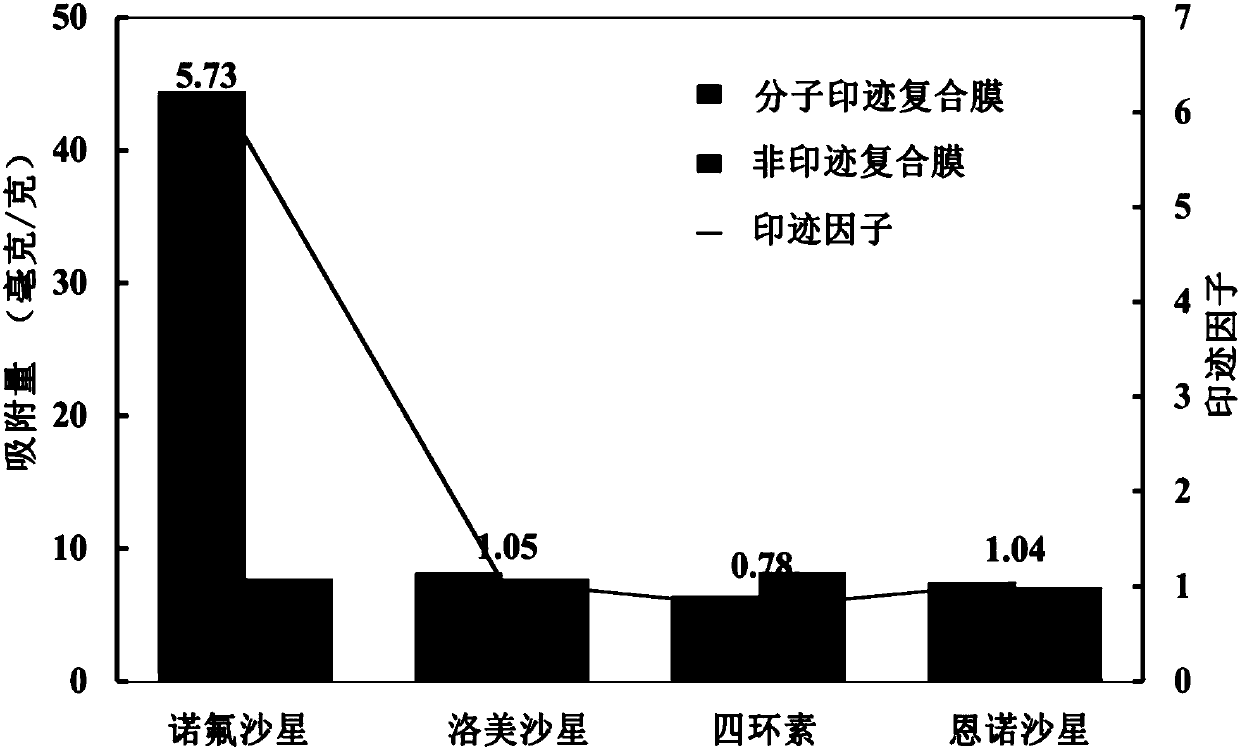

A technology of molecular imprinting and composite membrane, which is applied in the preparation of test samples, chemical instruments and methods, membrane technology, etc., can solve the problem of inability to simultaneously realize the effective separation of molecular and ionic impurities, single and selective separation of certain substances and other problems, to achieve the effect of fast adsorption kinetics, high selectivity, and many times of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of graphene oxide

[0043] Graphene oxide was synthesized based on a modified Hummer method. 1 g graphite and 2.5 g NaNO 3 Disperse in 30 mLH 2 SO 4 The three-necked flask was placed in an ice-water bath, and after stirring constantly, 3 g of KMnO 4 Gradually add a small amount of concentrated sulfuric acid to the mixed nitric acid and react for 2 h. The resulting mixture was heated to 35 °C and 40 mL of deionized water was added slowly over 15 min, maintaining the temperature at 98 °C for 40 min. To remove excess KMnO 4 and MnO 2 , add 10 mL of hydrogen peroxide. The obtained mixed solution was repeatedly washed with deionized water until the pH value of the solution reached about 7.0. After the synthesized product was centrifuged, it was repeatedly washed with deionized water and ethanol several times, and dried in vacuum for use.

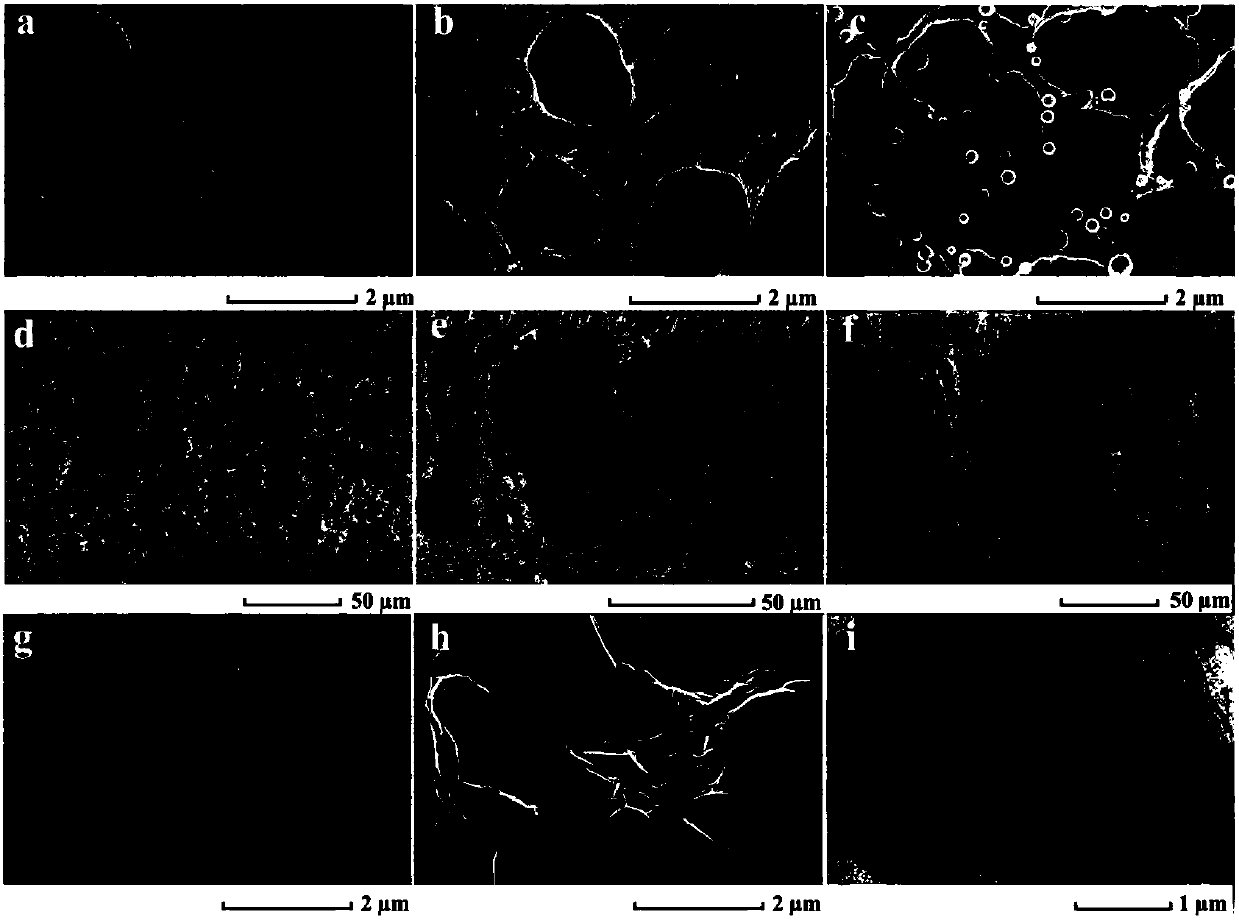

[0044] (2) Preparation of GO / PVDF blend membrane

[0045] 50 mg graphene oxide was dispersed in DMF, and after u...

Embodiment 2

[0061] (1) Preparation of graphene oxide

[0062] Graphene oxide was synthesized based on a modified Hummer method. 2 g graphite and 2.5 g NaNO 3 Disperse in 30 mLH 2 SO 4 The three-necked flask was kept stirring in an ice-water bath, and then 3 g KMnO 4 Gradually add a small amount of concentrated sulfuric acid to the mixed nitric acid and react for 2 h. The resulting mixture was heated to 35 °C and 40 mL of deionized water was added slowly over 15 min, keeping the temperature at 98 °C for 40 min. To remove excess KMnO 4 and MnO 2 , add 10 mL of hydrogen peroxide. The obtained mixed solution was washed repeatedly with deionized water until the pH value of the solution reached about 7.0, the synthesized product was centrifuged, washed several times with deionized water and ethanol, and dried in vacuum for use.

[0063] (2) Preparation of GO / PVDF blend membrane

[0064] 100 mg of graphene oxide was dispersed in DMF, ultrasonically dissolved for 30 min, and 8 g of PVDF ...

Embodiment 3

[0080] (1) Preparation of graphene oxide

[0081] Graphene oxide was synthesized based on a modified Hummer method. 2 g graphite and 2.5 g NaNO 3 Disperse in 30 mLH 2 SO 4 The three-necked flask was kept stirring in an ice-water bath, and then 3 g KMnO 4 Gradually add a small amount of concentrated sulfuric acid to the mixed nitric acid and react for 2 h. The resulting mixture was heated to 35 °C and 40 mL of deionized water was added slowly over 15 min, keeping the temperature at 98 °C for 40 min. To remove excess KMnO 4 and MnO 2 , add 10 mL of hydrogen peroxide. The obtained mixed solution was washed repeatedly with deionized water until the pH value of the solution reached about 7.0, the synthesized product was centrifuged, washed several times with deionized water and ethanol, and dried in vacuum for use.

[0082] (2) Preparation of GO / PVDF blend membrane

[0083] 100 mg of graphene oxide was dispersed in DMF, ultrasonically dissolved for 30 min, and 8 g of PVDF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com