Pulse hot pressing welding machine

A technology of thermocompression welding and thermocompression welding, which is applied in metal processing, assembly of printed circuits with electrical components, etc. It can solve problems such as uneven solder joint size, low efficiency, and affecting production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

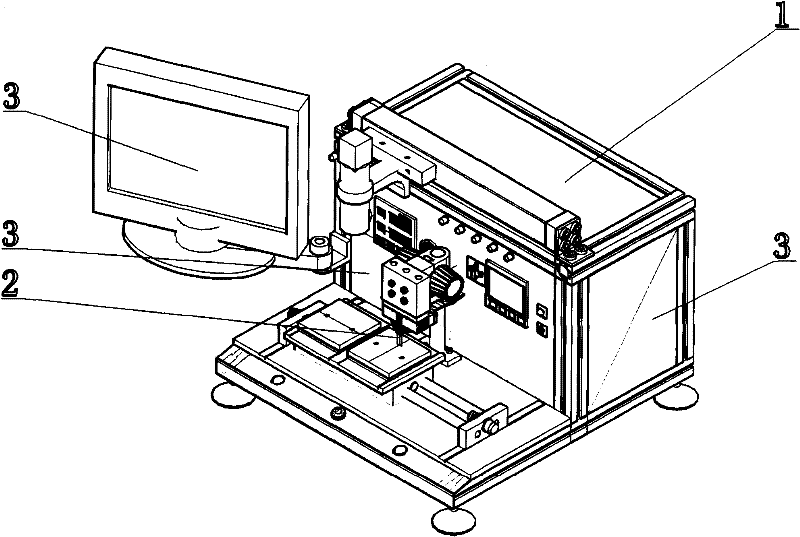

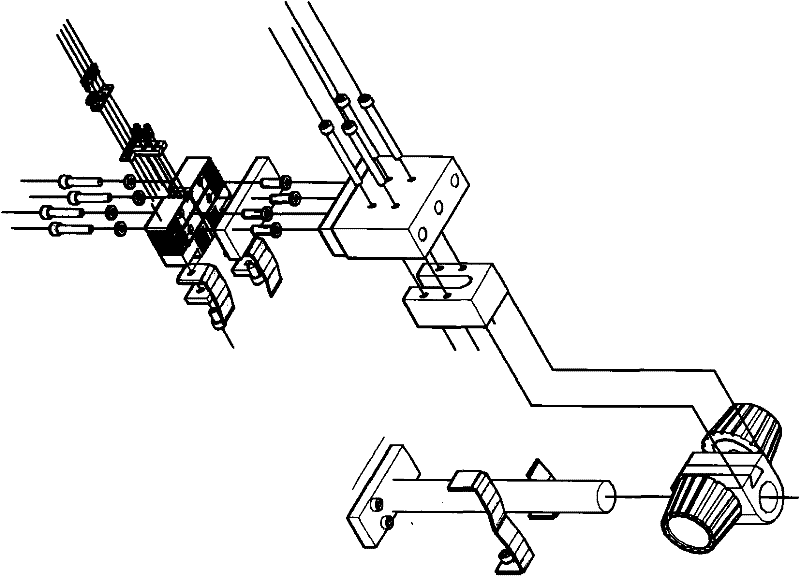

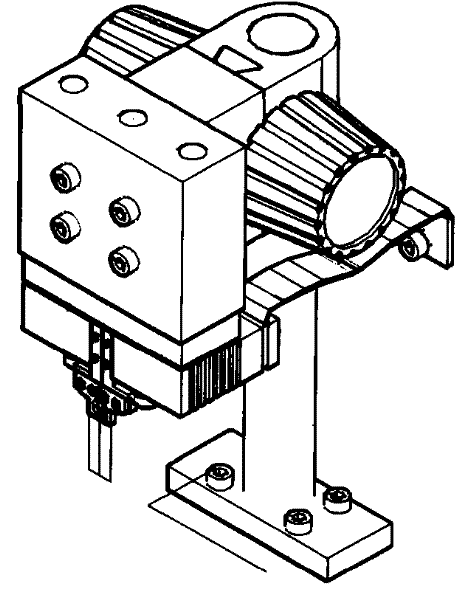

[0016] Such as Figures 1 to 5 As shown, a pulse thermocompression welding machine includes a host 1 capable of thermocompression welding, a heating radiator 2, a pulse thermocompression head 3, and a voltage inside the main body 1 is provided outside the host 1 to protect the internal voltage of the main body. The power supply device, the display screen 4 arranged on one side of the host 1, the air cylinder, the air gauge, the temperature controller, the magnifying glass, and the manual switch. Host 1 includes a transformer, a PLC programmer, a power regulator, a DC power supply device, an electromagnetic reversing valve, and a circuit protection device. , fuses, etc.) to protect the host 1 and convert the 220V voltage into an internal 4V voltage for the first circuit that provides voltage for heating, and convert the circuit into a 24V DC power supply to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com