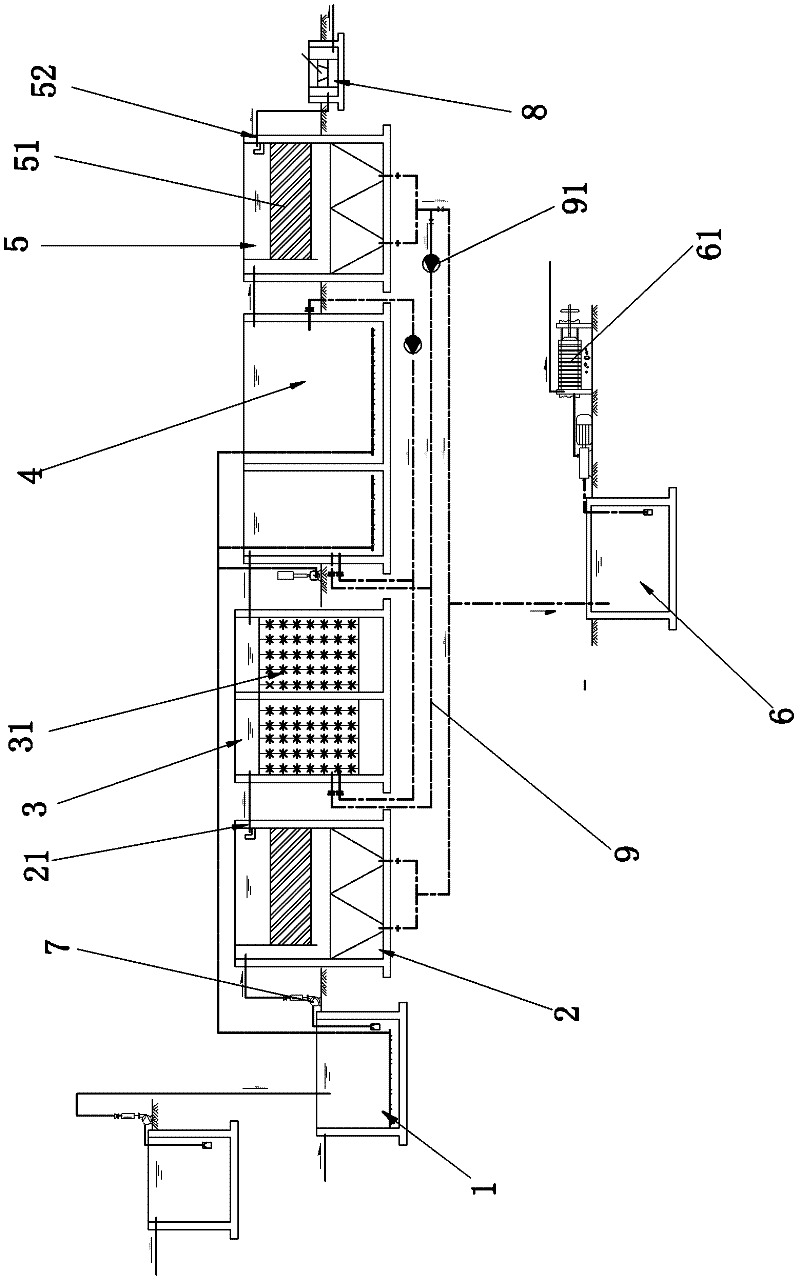

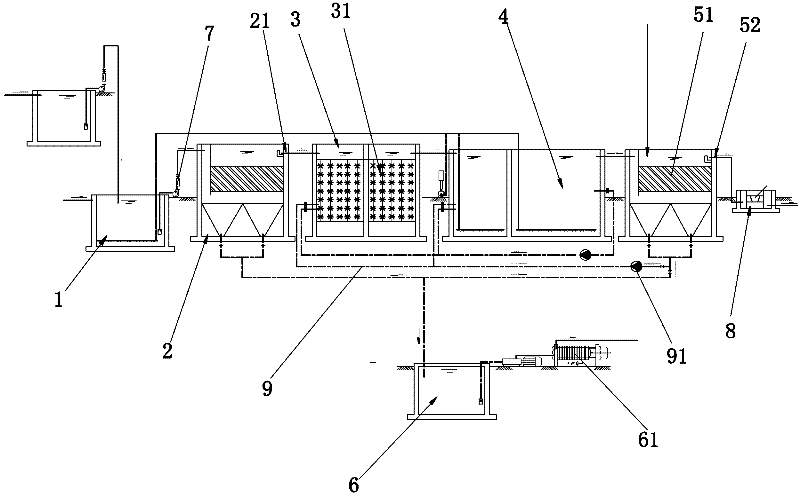

Method and device for treating caprolactam-containing waste water

A caprolactam and treatment method technology, which is applied in the field of caprolactam-containing wastewater treatment method and its treatment device, can solve the problems of lower denitrification efficiency, long sludge age, and difficulty in reaching the standard of effluent water quality, and achieve high denitrification efficiency and easy treatment effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Put the production wastewater to be treated into the regulating tank, and set up a pre-aeration device in the regulating tank. The pre-aerating device is a perforated aeration tube. Pre-aeration treatment is carried out in the regulating tank, and the dissolved oxygen in the controlling tank is less than 0.5mg / L. The production wastewater after pre-aeration is pumped into the coagulation sedimentation tank, and the coagulant ferrous sulfate is added to the coagulation sedimentation tank for coagulation and sedimentation. The production wastewater is stratified after coagulation and sedimentation, and the upper layer is the supernatant. The lower layer is sludge, and the sludge is sent to the sludge tank;

[0029] (2) The supernatant produced by coagulation and sedimentation overflows into the anoxic tank, and YDTZ elastic combined packing is installed in the anoxic tank, and the volume of YDTZ elastic combined packing accounts for 70% of the anoxic tank. Attached ...

Embodiment 2

[0036] (1) Put the production wastewater to be treated into the regulating tank, and set up a pre-aeration device in the regulating tank. The pre-aerating device is a perforated aeration tube. Pre-aeration treatment is carried out in the regulating tank, and the dissolved oxygen in the controlling tank is less than 0.5mg / L. The production wastewater after pre-aeration is pumped into the coagulation sedimentation tank, and the coagulant polyaluminium chloride is added to the coagulation sedimentation tank for coagulation and sedimentation. The production wastewater is stratified after coagulation and sedimentation, and the upper layer is the supernatant , the lower layer is sludge, and the sludge is sent to the sludge pool;

[0037] (2) The supernatant produced by coagulation and sedimentation overflows into the anoxic tank, and YDTZ elastic combined packing is installed in the anoxic tank, and the volume of YDTZ elastic combined packing accounts for 70% of the anoxic tank. A...

Embodiment 3

[0044] (1) Put the production wastewater to be treated into the regulating tank, and set up a pre-aeration device in the regulating tank. The pre-aerating device is a perforated aeration tube. Pre-aeration treatment is carried out in the regulating tank, and the dissolved oxygen in the controlling tank is less than 0.5mg / L. The production wastewater after pre-aeration is pumped into the coagulation sedimentation tank, and the coagulant ferrous sulfate is added to the coagulation sedimentation tank for coagulation and sedimentation. The production wastewater is stratified after coagulation and sedimentation, and the upper layer is the supernatant. The lower layer is sludge, and the sludge is sent to the sludge tank;

[0045] (2) The supernatant produced by coagulation and sedimentation overflows into the anoxic tank, and YDTZ elastic combined packing is installed in the anoxic tank, and the volume of YDTZ elastic combined packing accounts for 70% of the anoxic tank. Attached ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com