Preparation method for aqueous polyurethane-polyurea dispersion

A water-based polyurethane and dispersion technology, which is applied in the preparation of chemical dispersion systems and the preparation of water-based polyurethane-polyurea water dispersions, can solve the problems of system viscosity increase, failure to emulsify normally, environmental pollution, etc., and achieve stability and mechanical properties Good, stable and controllable reaction process, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

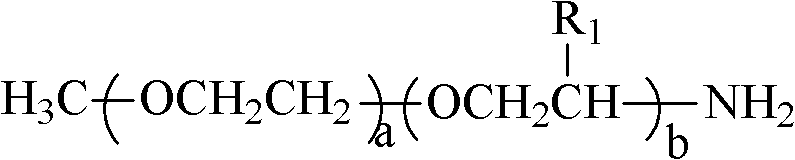

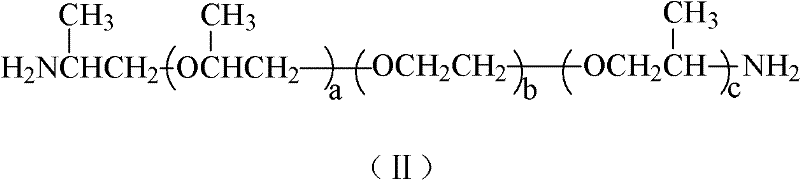

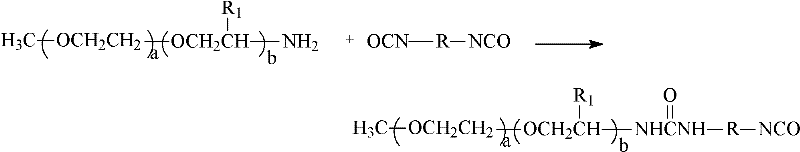

Method used

Image

Examples

Embodiment 1

[0033] 2000ml three-neck flask, equipped with thermometer, stirring, water bath and stirring device. Add 791g deionized water to the three-necked flask under ice-water bath conditions, add 50g JEFFAMINE M-2070 (polyether monoamine, average relative molecular weight 2000, EO / PO=31 / 10) under stirring conditions, stir and dissolve into a uniform solution, and then Add 16g of sodium lauryl sulfate, and control the temperature of the system at 0°C to 2°C; then weigh 200g of GE-220 (polyether polyol, with an average relative molecular weight of about 2000, and a hydroxyl value of 54.5 to 57.5mg KOH / g) and 40g of iso Phortone diisocyanate was mixed evenly, added into a three-necked flask, stirred rapidly for 10 minutes under ice-water bath conditions, and the temperature of the system was controlled at 0°C to 2°C to obtain a light blue transparent microemulsion. Then, under low-speed stirring, add 0.1g organic bismuth catalyst (Neobi 200, metal bismuth content 19.3-20.7%), slowly hea...

Embodiment 2

[0035] 2000ml three-neck flask, equipped with thermometer, stirring, water bath and stirring device. Add 740g deionized water to the three-necked flask under ice-water bath conditions, add 50g JEFFAMIN ED-600 (polyether diamine, average relative molecular weight 600, EO / PO molar ratio = 9 / 3.6) under stirring conditions, stir and dissolve into a uniform solution , add 10g of sodium lauryl sulfate, and control the temperature of the system at 0°C to 2°C; then weigh 180g of polyoxypropylene glycol (PPG, with an average relative molecular weight of about 2000, and a hydroxyl value of 106 to 118mgKOH / g) and 31.5g Mix hexamethylene-1,6-diisocyanate evenly, add it into a three-necked flask, stir rapidly for 10 minutes in an ice-water bath, and control the temperature of the system at 0°C to 1°C to obtain a light blue transparent microemulsion. Then, under low-speed stirring, add 0.1 g of dibutyltin laurate and 0.1 g of organic bismuth catalyst (Neobi 200, metal bismuth content 19.3 t...

Embodiment 3

[0037]2000ml three-neck flask, equipped with thermometer, stirring, water bath and stirring device. Add 405g of deionized water to the three-necked flask under ice-water bath conditions, add 30g of JEFFAMIN ED-900 (polyether diamine, average relative molecular weight 900, EO / PO molar ratio = 12.5 / 6.0) under stirring conditions, and stir to dissolve into a uniform solution , add 10g sodium dodecylbenzenesulfonate (analytically pure, active ingredient content ≥ 95%), and control the temperature of the system at 0°C to 2°C; then weigh 76g refined castor oil and 30.2g 4,4'-isocyanate ring Hexyl ester methane (MDA, purity ≥ 99.5%) was mixed evenly, added to a three-necked flask, stirred rapidly for 10 minutes under ice-water bath conditions, and the system temperature was controlled at 0°C to 2°C to obtain a light blue transparent microemulsion. Then, under low-speed stirring, add 0.1g organic bismuth-type catalyst (Neobi 200, metal content 19.3-20.7), slowly raise the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com