Acid gel fracturing fluid and preparation method thereof

A jelly fracturing fluid and acidic technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as formation damage, achieve a small amount of liquid entering the ground, a high liquid flowback rate, and improve production stimulation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

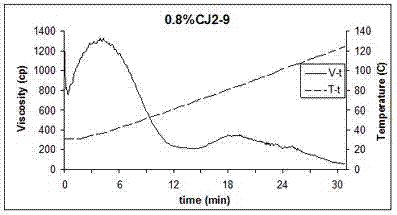

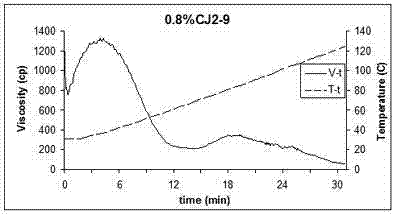

Image

Examples

Embodiment 1

[0036] Each material is proportioned by the following parts by weight:

[0037] 94.9 parts of water

[0038] Thickener CJ2-9 0.6 parts

[0039] 0.7 parts of organoaluminum crosslinking agent

[0040] Hydrocarbon emulsifier 1.00 parts

[0041] Ammonium chloride 0.80 parts.

[0042] After each material is proportioned according to the above parts by weight, it is realized through the following steps:

[0043] (1) Preparation of solution A: Add water to the container, and slowly add thickener CJ2-9, ammonium chloride and hydrocarbon emulsifier while circulating with a pump or agitator, and continue to circulate after adding Or stir for 30 minutes so that the liquid is fully mixed to form solution A.

[0044] (2) During fracturing construction, while pumping solution A, mix solution A and organoaluminum crosslinking agent according to the volume ratio of solution A: organoaluminum crosslinking agent = 100:0.7 to form fracturing fluid . the

Embodiment 2

[0046] Each material is proportioned by the following parts by weight:

[0047] 95.9 parts of water

[0048] Thickener CJ2-9 0.75 parts

[0049] Organoaluminum crosslinking agent 0.85 parts

[0050] 1.5 parts of alkyl sulfonate emulsifier

[0051] Ammonium chloride 1 part.

[0052] After each material is proportioned according to the above parts by weight, it is realized through the following steps:

[0053] (1) Preparation of solution A: Add water to the container, and slowly add thickener CJ2-9, ammonium chloride and alkyl sulfonate emulsifier while stirring with a pump or stirrer, add Continue to circulate or stir for 30 minutes after completion, so that the liquid is fully mixed to form solution A.

[0054] (2) During fracturing construction, while pumping solution A, mix solution A and organoaluminum crosslinking agent according to the volume ratio of solution A: organoaluminum crosslinking agent = 100:0.85 to form fracturing fluid . the

Embodiment 3

[0056] Each material is proportioned by the following parts by weight:

[0057] 96.9 parts of water

[0058] Thickener CJ2-9 0.9 parts

[0059] 1.0 parts of organoaluminum crosslinking agent

[0060] Alkyl sulfate emulsifier 2.0 parts

[0061] Ammonium chloride 1.2 parts.

[0062] After each material is proportioned according to the above parts by weight, it is realized through the following steps:

[0063] (1) Preparation of solution A: Add water to the container, and slowly add thickener CJ2-9, ammonium chloride and alkyl sulfate emulsifier under the condition of circulating with a pump or agitator, and finish adding Then continue to circulate or stir for 30 minutes, so that the liquid is fully mixed to form solution A.

[0064] (2) During fracturing construction, while pumping solution A, mix solution A and organoaluminum crosslinking agent according to the volume ratio of solution A: organoaluminum crosslinking agent = 100:1.0 to form fracturing fluid . the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com