Method for preparing anti-fingerprint film for touch screen

An anti-fingerprint film and touch screen technology, applied in ion implantation plating, gaseous chemical plating, coating, etc., can solve the problems of high smoothness on the surface of the buffer layer and limit the adhesion of the coating, and achieve the effect of improving the adhesion of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the specific technical content of the invention, the following in conjunction with the embodiments and accompanying drawings describe in detail:

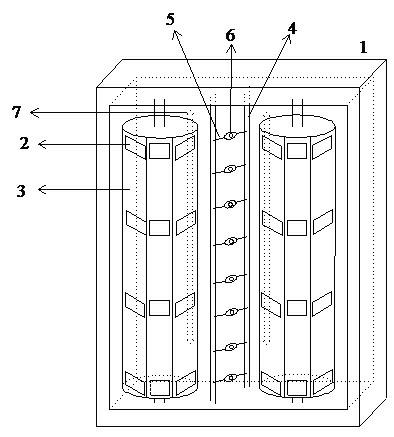

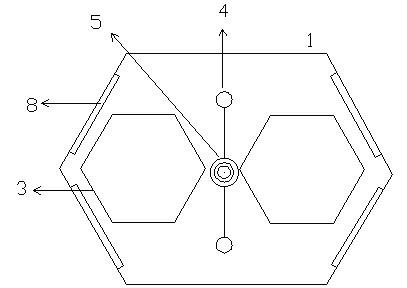

[0021] like figure 1 As shown, in the vacuum chamber 1, the strengthened glass substrate 2 is adhered to the fixture 3, and the filament fixture 4 is clamped with 8 filaments 5, and each of the 8 filaments 5 contains 8 pieces of film material 6, and 7 is a gas pipeline.

[0022] The pressure in the vacuum chamber 1 is pumped to 10 -3 mbar, and then through the gas pipeline 7 to the vacuum chamber 1 into the gas flow rate of 500sccm O 2 and 300sccm Ar to a pressure of 1.0 x 10 -4 ~2.0×10 -2 Between mbar, add intermediate frequency power of 6000w, and then rise to 8000w within 5s to discharge and start for 30s, which can clean and etch the surface of the glass substrate.

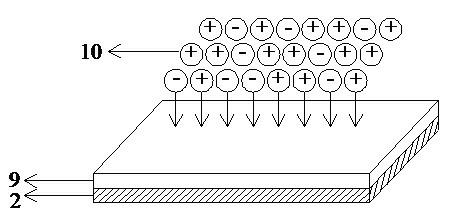

[0023] After the etching is completed, the vacuum chamber 1 is evacuated to a pressure of 5.0×10 -3 mbar, then filled wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap