High-power LED (light emitting diode) spotlight and production process thereof

An LED spotlight, high-power technology, used in refractors, cooling/heating devices for lighting devices, lighting and heating equipment, etc., can solve problems such as difficulty in guaranteeing the service life of LEDs, decline in LED luminous efficiency, and affecting the service life of lamps and lanterns. , to achieve the effect of light weight, low temperature rise and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

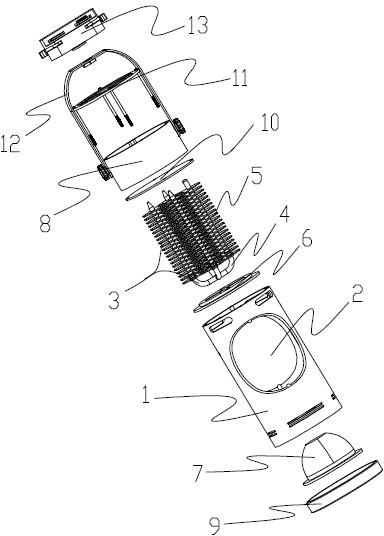

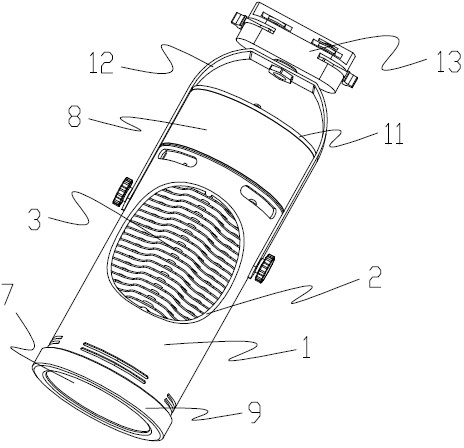

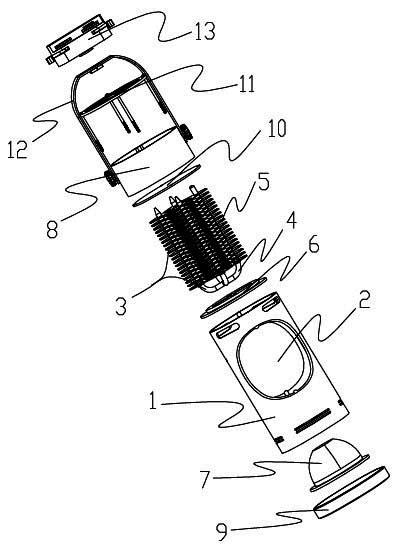

[0038] As shown in the drawings of the description, the present invention includes an outer shell 1, which is an aluminum hollow cylinder structure, and a group of symmetrical openings 2 are arranged on the outer shell 1, and the openings 2 are beneficial to Hot air convection. The outer casing 1 is provided with a heat dissipation module 3 inside, and the heat dissipation module 3 includes a heat pipe 4 and a plurality of heat sinks 5. The heat pipe 4 is provided with two groups, and the heat pipe 4 is bent in an L shape. The heat sink 5 Welded on the heat pipe 4 to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com