Intermittent type vacuum microwave drying device and method for processing core material of vacuum heat insulation plate by using intermittent type vacuum microwave drying device

A vacuum microwave drying and microwave drying technology, which is applied in the direction of drying gas arrangement, method combination to dry solid materials, drying solid materials, etc., can solve the problems of high equipment operation cost, insufficient and effective use of heat, and large energy consumption, etc., to achieve Good economic and environmental benefits, easy to realize automatic control, and high-efficiency control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

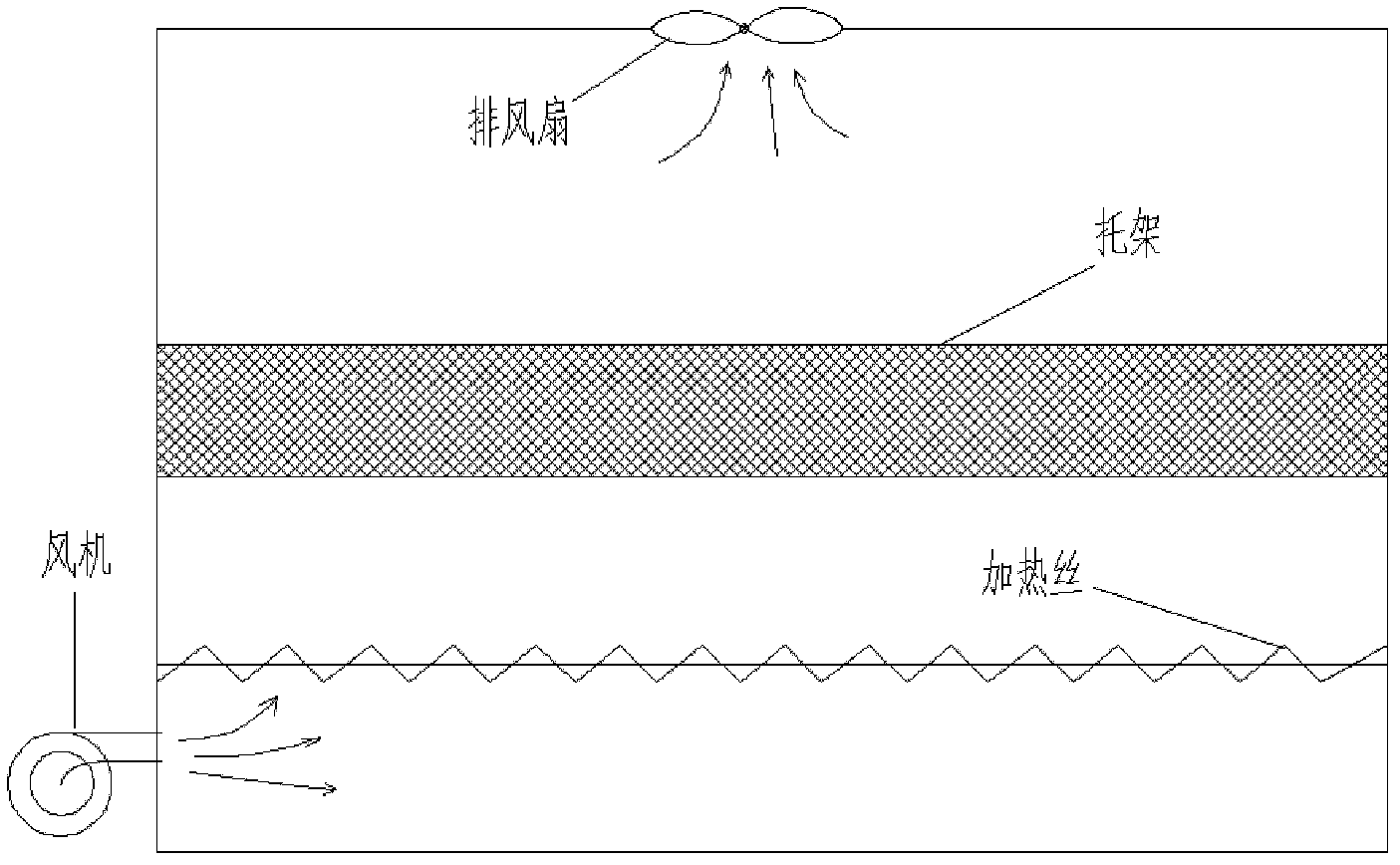

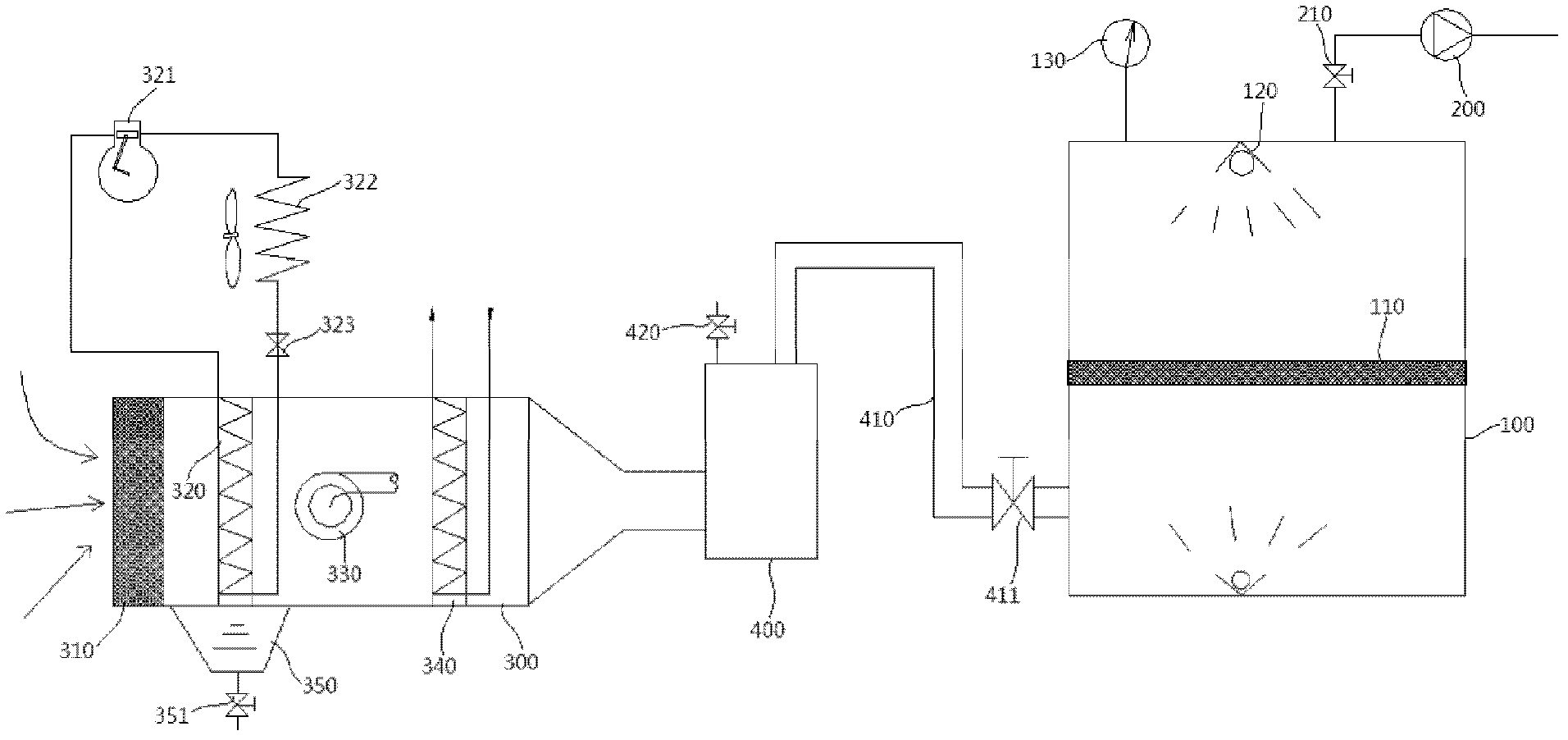

[0053] Embodiment 1: the drying of glass fiber core material

[0054] Wet-pressed glass fiber core material, the size is 1000×800×20mm, put it flat on the bracket, close the drying room, preheat with microwave (1800W~2000W) for 2 minutes, the temperature rises to 50~60℃, and vacuumize After the temperature reaches 600Pa, add dry air, pour into the dry air at a temperature of about 50°C, repeat the above action once, until the final moisture content is below 1%, take out the packaged product.

Embodiment 2

[0055] Embodiment 2: the drying of open cell microporous polyurethane core material

[0056] Take out the open-cell microporous polyurethane core material produced by foaming in the abrasive tool, cut it into 1000×800×20mm size according to the requirements, remove the waxy layer of the skin, put it on the bracket, and close the drying room for microwave preheating ( 1800W~2000W) for 2 minutes, the temperature rises to about 50°C, vacuumize to 600Pa and hold the pressure for 1 minute, add dry air, and the temperature of the dry air is about 50°C, because the foaming agent and moisture contained in the micropores are difficult To remove, repeat the above action twice until the final moisture content is below 1%, then take out the packaged product.

Embodiment 3

[0057] Embodiment 3: drying of fly ash core material

[0058] Pre-press the finely ground fly ash particles into a flat plate with a size of 1000×800×20mm, wrap it with protective yarn, put it flat in the bracket, close the drying room, and preheat with microwave (1800W~2000W) for 2 minutes , the temperature rises to 50-60°C, and after vacuuming to 600Pa, dry air is added, and the temperature of the dry air is about 50°C, until the final moisture content is below 1%, and the packaged product is taken out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com