Method for abstracting and enriching organic phosphorus in substrate sludge

An organic phosphorus and sediment technology, applied in the preparation of test samples, etc., can solve the problems of organic phosphorus content that cannot meet the measurement requirements, low spectral resolution and signal-to-noise ratio, etc., to reduce the time required for measurement, reduce the Measuring the effect of costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

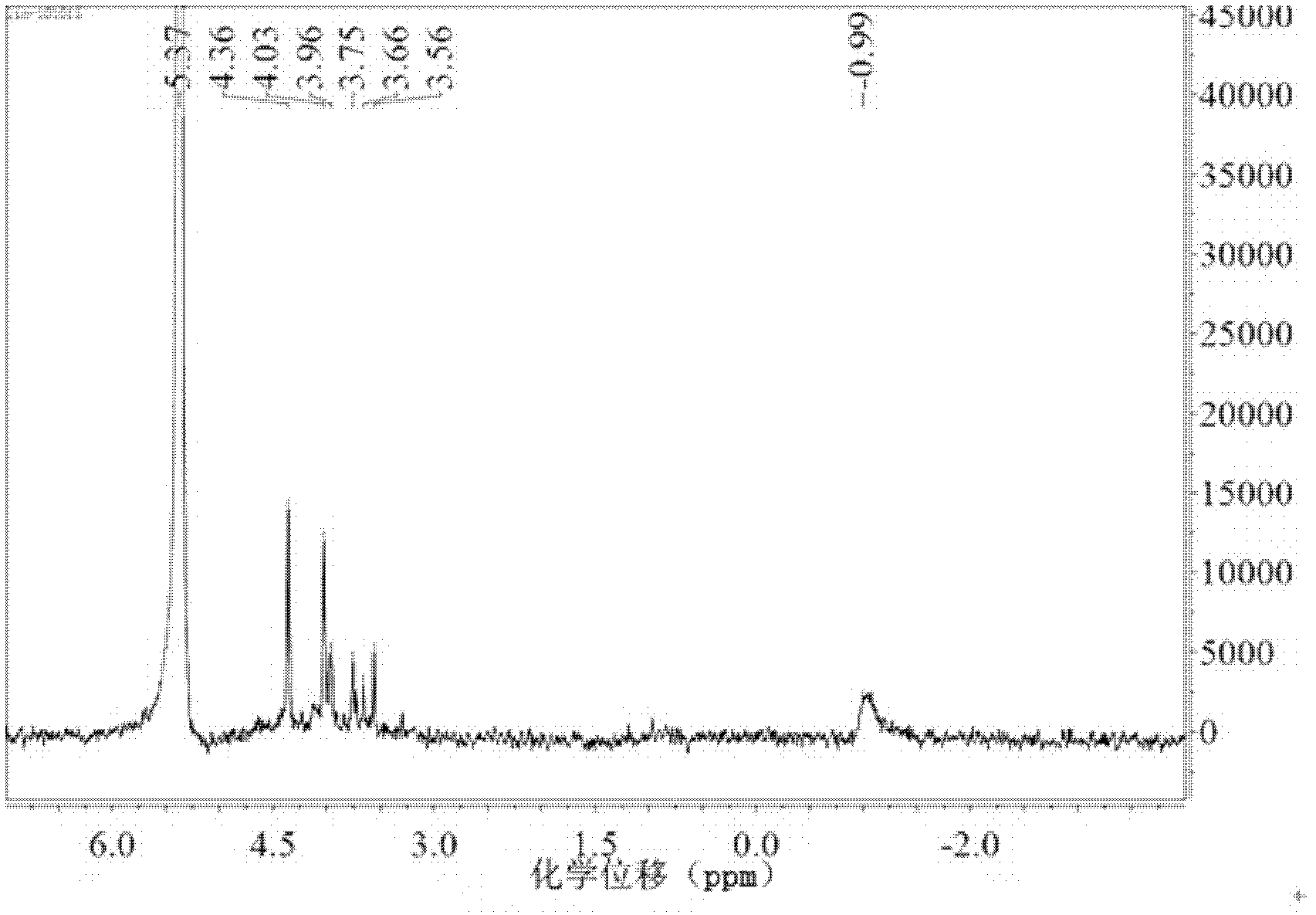

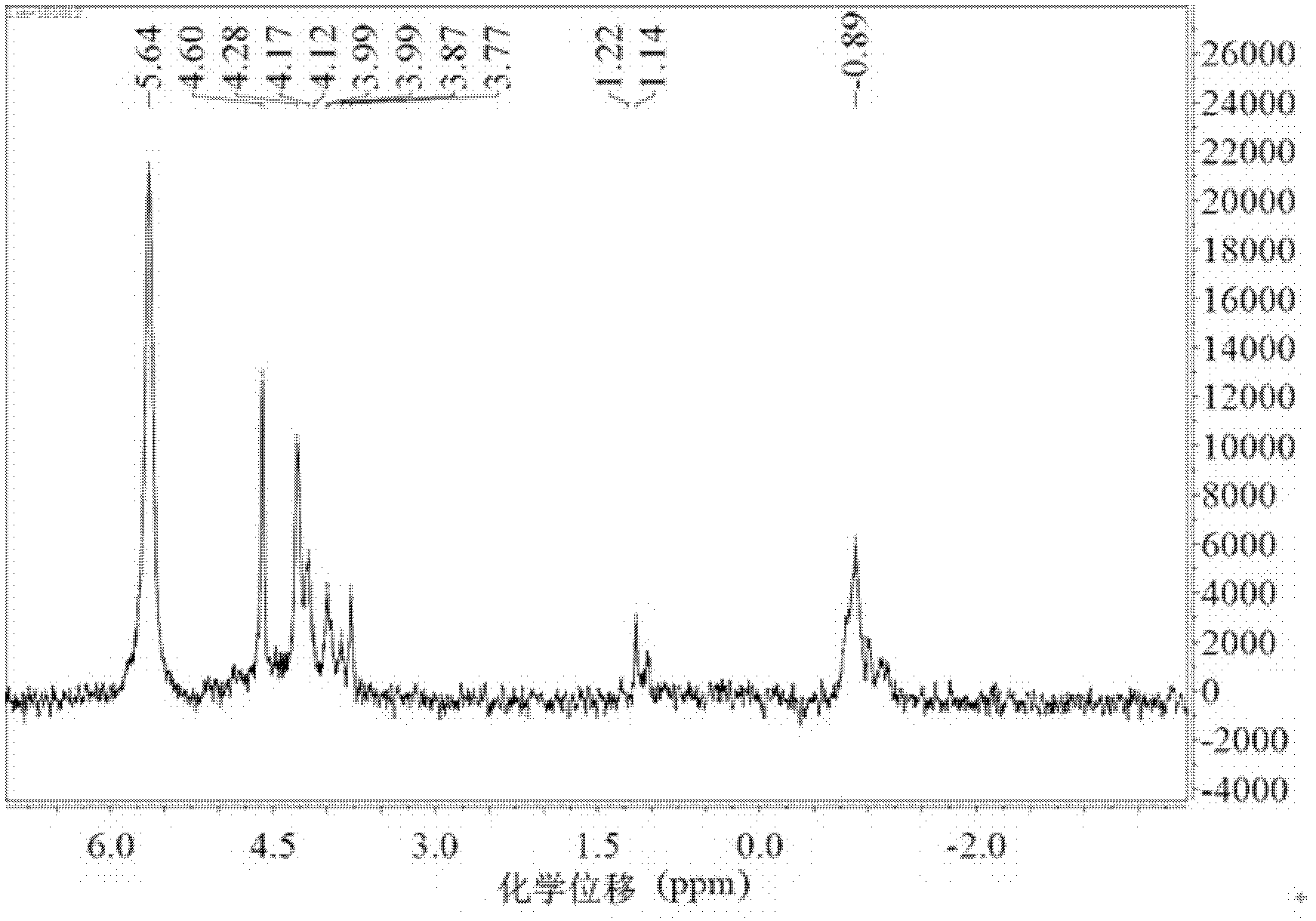

[0060] Implementation example 1 and implementation example 2 adopt the same sample, by comparing the spectrogram 2 detected by the traditional method and the spectrogram 3 detected by the foam separation method, it can be known that under the condition that the signal-to-noise ratio and the resolution do not decrease, the foam separation method ( The measurement takes 8h) compared with the traditional method (the measurement takes 12h), and the time required is shortened to 2 / 3 of the original, which shortens the time required for the measurement and reduces the test cost.

[0061] Foam separation method is used for the enrichment of sediment phosphorus, as shown in Figure 3, the spectrogram is at the chemical shift of 1.14ppm, and the phosphoric acid diester signal peak that cannot be detected by traditional methods is detected, so the foam separation method is used to extract and an effective method for enriching organic phosphorus in sediment.

Embodiment 3

[0063] (1) bottom mud sample adopts the sample of implementation example 1

[0064] (2) freeze-drying of sample: with implementation example 1

[0065] (3) Extraction of organic phosphorus in sediment

[0066] Take 300g of the dried mud sample obtained in step (2), add it to 3L of 0.25mol / L NaOH solution, place the solution on a constant temperature shaker at 25°C, and shake and extract for 12h;

[0067] (4) Remove impurities in the solution

[0068] Centrifuge the bottom sludge mixture prepared in step (3) at 4000rpm / min for 30min to remove most of the bottom sludge impurities, then centrifuge the supernatant solution obtained by centrifugation at 10000rpm / min for 30min, then filter it with a 0.45μm filter membrane and collect filtrate;

[0069] (5) the adjustment of filtrate pH: with implementation example 1;

[0070] (6) Separation of organophosphorus in the extract: with implementation example 1

[0071] (7) organophosphorus solution freeze-drying again: with implemen...

Embodiment 4

[0076] (1) bottom mud sample adopts implementation example 1 sample

[0077] (2) freeze-drying of sample: with implementation example 1

[0078] (3) Extraction of organic phosphorus in the bottom mud: with implementation example 1

[0079] (4) remove impurities in the solution: with implementation example 1

[0080] (5) Adjustment of filtrate pH

[0081] The filtrate contains a large amount of sodium hydroxide, and the pH is strongly alkaline, which is not conducive to the formation of foam. The pH of the solution needs to be adjusted, and the pH value of the solution is adjusted to 6.0 with 3mol / L HCl;

[0082] (6) Separation of organophosphorus in the extract: with implementation example 1

[0083] (7) organophosphorus solution freeze-drying again: with implementation example 1

[0084] (8) nuclear magnetic resonance measurement of sample: with implementation example 1

[0085] (9) Measurement results

[0086] The measurement results show that compared with the traditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com