Method for qualitatively testing molecular weight distribution of ultrahigh molecular weight polyethylene (UHMWPE)

A technology of ultra-high molecular weight and molecular weight distribution, which is applied in the testing field of qualitative comparison and judgment of molecular weight distribution of ultra-high molecular weight polyethylene, can solve problems such as difficulty in obtaining molecular weight distribution curves accurately, small amount of molecular weight substances, and large test errors, etc., to achieve Good adaptability, low cost and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

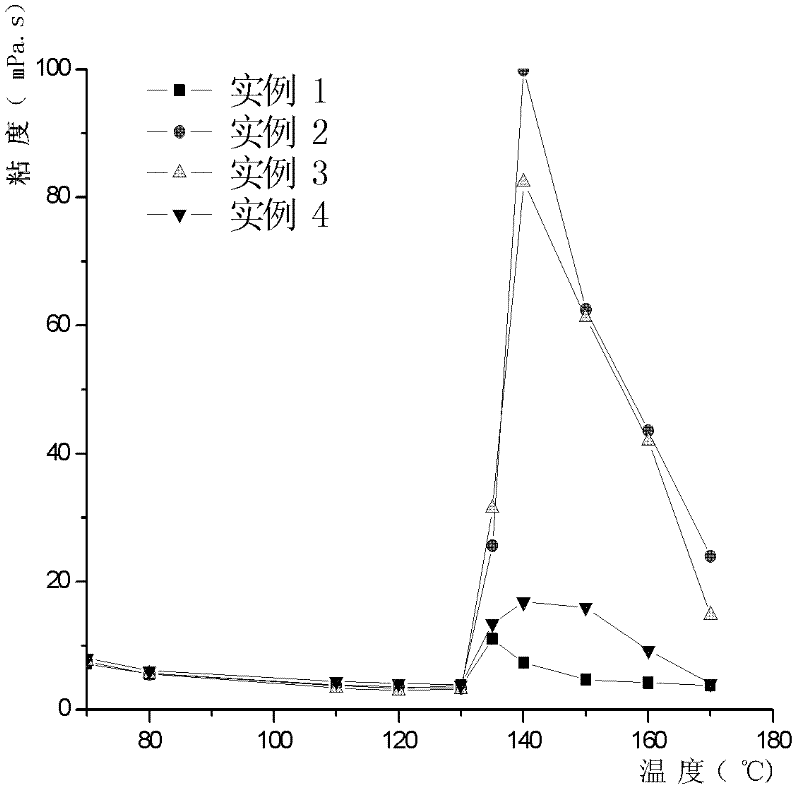

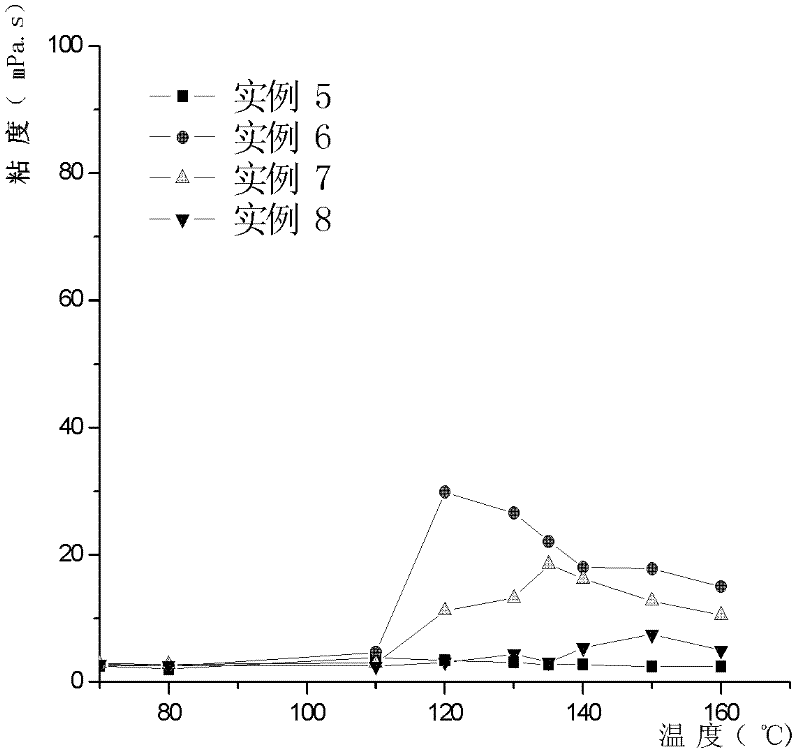

Embodiment 1

[0038] Weigh a certain amount of GUR4022UHMWPE powder and antioxidant, add a certain amount of white oil solvent, and place this mixture in a three-necked flask. Install the stirring and heating device, and adjust the heating and stirring rate. A very dilute solution with a concentration of 0.02g / 100mL. Use NDJ-1 at different temperatures of 70℃, 80℃, 110℃, 120℃, 130℃, 135℃, 140℃, 150℃, 160℃ and 170℃. In the standard test of the type rotary viscometer, the viscosity is measured on the No. 1 rotor at 60 rpm. Each test temperature needs to be kept at a constant temperature for 15 minutes, and the viscosity readings are recorded at intervals of 3 viscosity values, and the average value is taken as the final result, and then the result is expressed as the standard sample A.

Embodiment 2

[0040] Weigh a certain amount of UHMWPE powder and antioxidant, add a certain amount of white oil solvent, and place this mixture in a three-necked flask. Install the stirring and heating device, and adjust the heating and stirring rate. Prepare a very dilute solution of sample B with a concentration of 0.02g / 100mL, at different temperatures of 70℃, 80℃, 110℃, 120℃, 130℃, 135℃, 140℃, 150℃, 160℃ and 170℃. The viscosity was measured using the NDJ-1 type rotary viscometer standard test on the No. 1 rotor at 60 rpm. Each test temperature needs to be kept at a constant temperature for 15 minutes, and the viscosity readings are recorded at intervals of 3 viscosity values, and the average value is taken as the final result, and then compared with Example 1 for evaluation.

Embodiment 3

[0042] Weigh a certain amount of UHMWPE powder and antioxidant, add a certain amount of white oil solvent, and place this mixture in a three-necked flask. Install the stirring and heating device, and adjust the heating and stirring rate. Prepare a very dilute solution of sample C with a concentration of 0.02g / 100mL, at different temperatures of 70℃, 80℃, 110℃, 120℃, 130℃, 135℃, 140℃, 150℃, 160℃ and 170℃. The viscosity was measured using the NDJ-1 type rotary viscometer standard test on the No. 1 rotor at 60 rpm. Each test temperature needs to be kept at a constant temperature for 15 minutes, and the viscosity readings are recorded at intervals of 3 viscosity values, and the average value is taken as the final result, and then compared with Example 1 for evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com