Test car used for testing rodless airplane tractor

A technology of aircraft tractors and test vehicles, which is applied in the field of test vehicles, can solve the problems of endangering the precious lives of passengers, high risks, losses of airports and airlines, etc., to enhance product testing capabilities, eliminate hidden dangers of accidents, and reduce economic losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

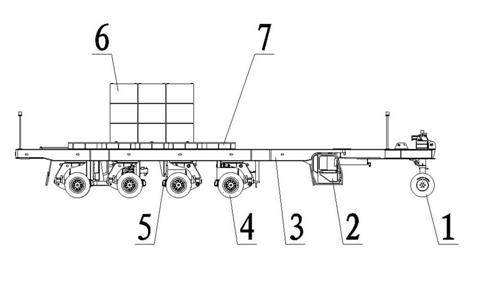

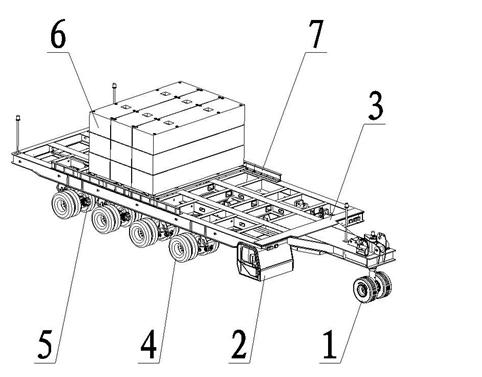

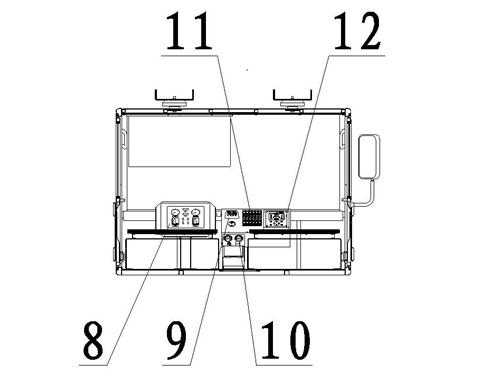

[0030] Below in conjunction with accompanying drawing, the present invention is further described:

[0031]As shown in the accompanying drawings, the test vehicle for detecting rodless aircraft tractors is characterized in that a load-bearing platform 3 is provided, and a cab 2, a power control system, a hydraulic control system and an electrical control system are arranged on the load-bearing platform 3, and the load-bearing The upper end of the platform 3 is provided with a counterweight assembly 6, and the lower end is provided with a support wheel set 4. The structure and connection relationship of the support wheel set 4 are the same as those of the prior art, and will not be repeated here. The front end is provided with a nose wheel device 1, and the load-bearing platform 3 is It is formed by intersecting and fixing the metal frame and the horizontal braces and vertical braces in the metal frame. The counterweight assembly 6 is formed by inserting and fixing the unit coun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com