Mansard-roof box wagon

A folding-line, boxcar technology, applied in the field of boxcar and railway freight car manufacturing, can solve the problems of poor cargo loading environment in the car, reduce the weight of the vehicle, increase the volume of the vehicle, etc., to improve the grip comfort, reduce the weight of the vehicle, expand the The effect of cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with example the present invention is further described.

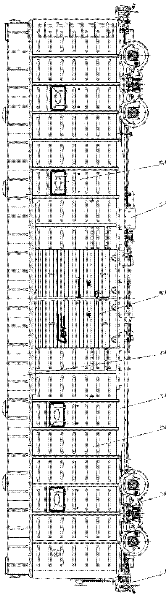

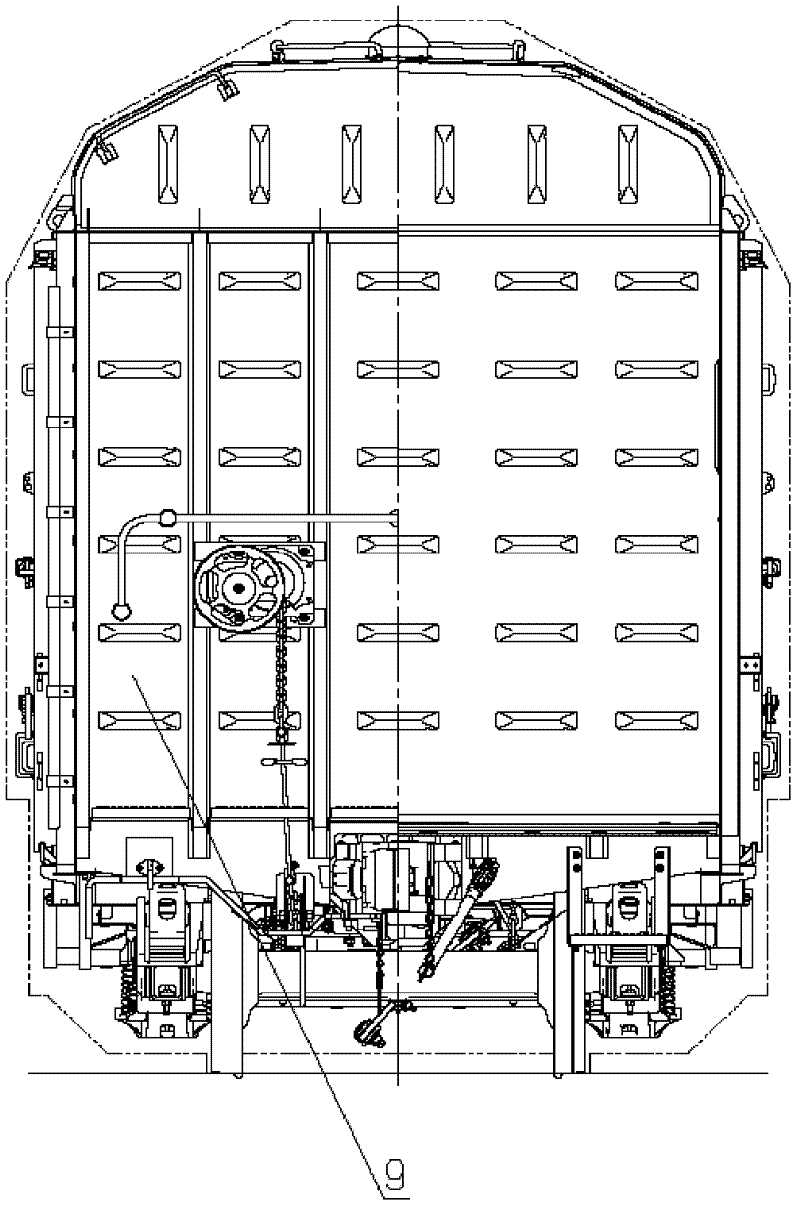

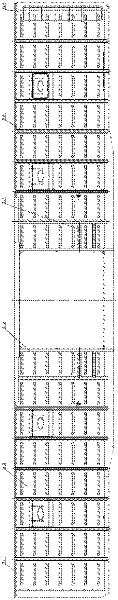

[0042] Such as Figure 1-9 , broken-line roof car, including coupler buffer device 1, bogie 2, side wall 3, underframe 4, roof 5, door 6, air brake device 7, window 8 and end wall 9; the roof 5 is Broken line shape; roof 5 includes roof panel 5.1, ventilator 5.2, roof curved beam 5.3, roof side beam 5.4, top curved beam 5.5 and top panel 5.6; side wall 3 is a plate-column structure; underframe 4 It is a grid beam structure; the end wall 9 is a straight beam structure.

[0043] The roof panel 5.1 is a buckled rib structure, the roof beam 5.3 is a flat steel beam structure, the roof side beam 5.4 and the roof beam 5.5 are cold-formed angle steel; The roof curved beam 5.3 is overlapped, and the roof panel 5.1 at the end is respectively overlapped with the roof curved beam 5.3 and the top curved beam 5.5; both ends of the entire roof panel 5.1 are overlapped with the roof side beam 5.4; the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com