Skin-imitated synthetic leather, and manufacturing method and apparatus for same

A manufacturing method and technology for synthetic leather, applied in the field of synthetic leather manufacturing, can solve the problems of poor leather feel, poor air permeability, easy wrinkling of synthetic leather, etc., and achieve the effects of strong leather feeling, soft hand feeling and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

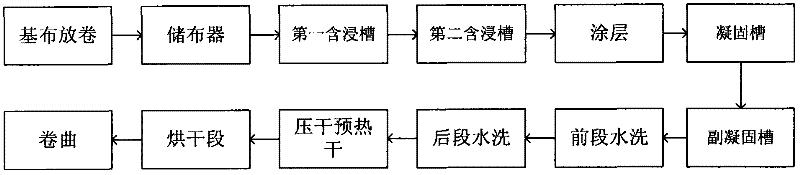

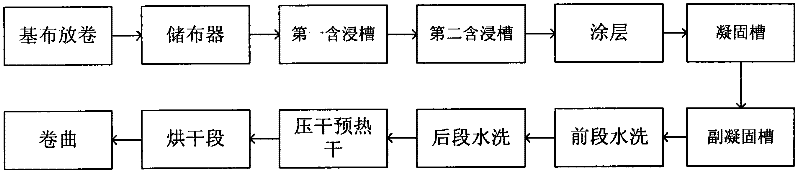

[0032] The manufacturing method of the artificial leather synthetic leather of the present invention comprises the following concrete technological process:

[0033] 1. Batching stage: including the preparation of impregnating slurry and coating slurry

[0034] The formula in parts by weight of the impregnating slurry is: 100 parts of special resin (Suzhou Asahikawa Chemical Co., Ltd., XCK-30C), 200 parts of DMF, 0.4 parts of defoamer (Wenzhou Keda Co., Ltd., 6603), 1.5 parts of wetting agent (Shanghai Rishen Chemical Co., Ltd., S-11), and 3 parts of color paste.

[0035] The preparation of the impregnating slurry includes the following steps: adding DMF to the impregnating tank, adding color paste, defoaming agent, wetting agent and special resin in sequence during the stirring of DMF, and controlling the viscosity of the slurry at 200cps.

[0036]The formula in parts by weight of the slurry used for coating is: 100 parts of special resin (Suzhou Asahikawa Chemical Co., Ltd....

Embodiment 2

[0047] Except for the following ingredients and conditions, the process flow steps of Example 2 are the same as those of Example 1.

[0048] The formula in parts by mass of the impregnating slurry is: 100 parts of special resin, 180 parts of DMF, 0.05 part of defoamer, 2 parts of wetting agent, and 5 parts of color paste.

[0049] The preparation of the impregnating slurry includes the following steps: adding DMF to the resin tank, adding color paste, defoaming agent, wetting agent and special resin in sequence during the stirring of DMF, and controlling the viscosity of the slurry to be 200cps.

[0050] The formula in parts by weight of the slurry used for coating is: 100 parts of special resin, 0.05 part of leveling agent, 1 part of kneading hand feeling agent, 0.02 part of defoaming agent, 0.5 part of three-dimensional foaming agent, 2 parts of color paste, And 25 servings of DMF.

Embodiment 3

[0052] Except for the following ingredients and conditions, the process flow steps of Example 3 are the same as those of Example 1.

[0053] The formula in parts by mass of the impregnating slurry is: 100 parts of special resin, 250 parts of DMF, 0.5 part of defoamer, 0.5 part of wetting agent, and 2 parts of color paste.

[0054] The preparation of the impregnating slurry includes the following steps: adding DMF to the resin tank, adding color paste, defoaming agent, wetting agent and special resin in sequence during the stirring of DMF, and controlling the viscosity of the slurry to be 200cps.

[0055] The formula of the slurry used for coating in parts by weight is: 100 parts of special resin, 1 part of leveling agent, 2 parts of kneading hand feeling agent, 0.5 part of defoamer, 2 parts of three-dimensional cell agent, 3 parts of color paste, And 45 servings of DMF.

[0056] By adopting the technical scheme of the present invention, the artificial leather synthetic leathe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com