Integrated finished wall as well as industrial production method and detaching method thereof

A production method and technology for finished walls, which are applied in the direction of walls, building maintenance, building components, etc., can solve problems such as difficult work, low work efficiency, and confusion at the construction site, so as to avoid environmental impact, overcome cumbersome construction, and reduce building space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

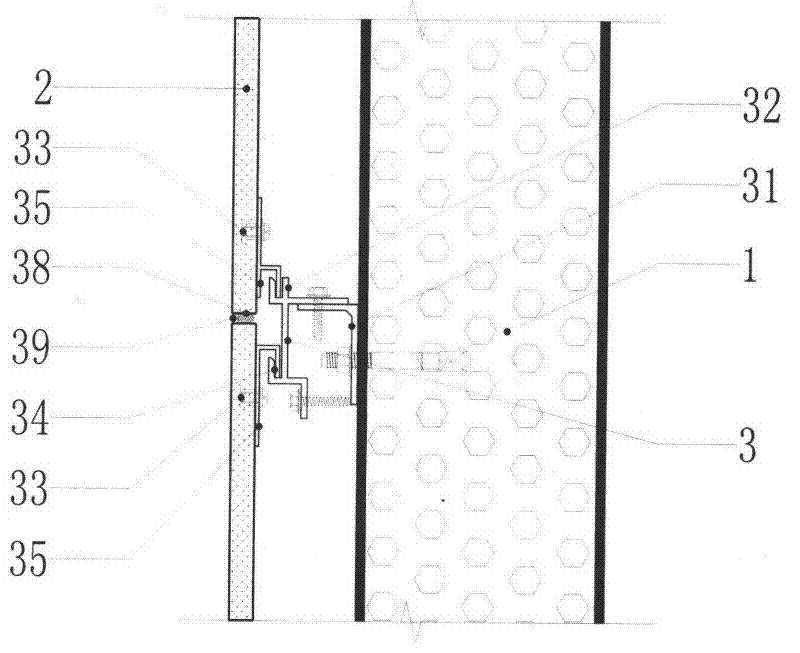

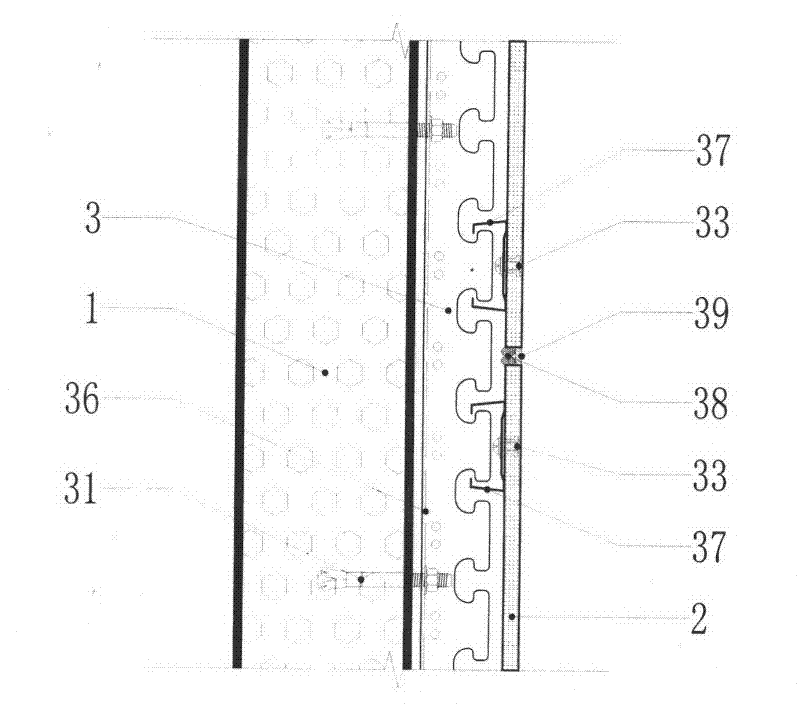

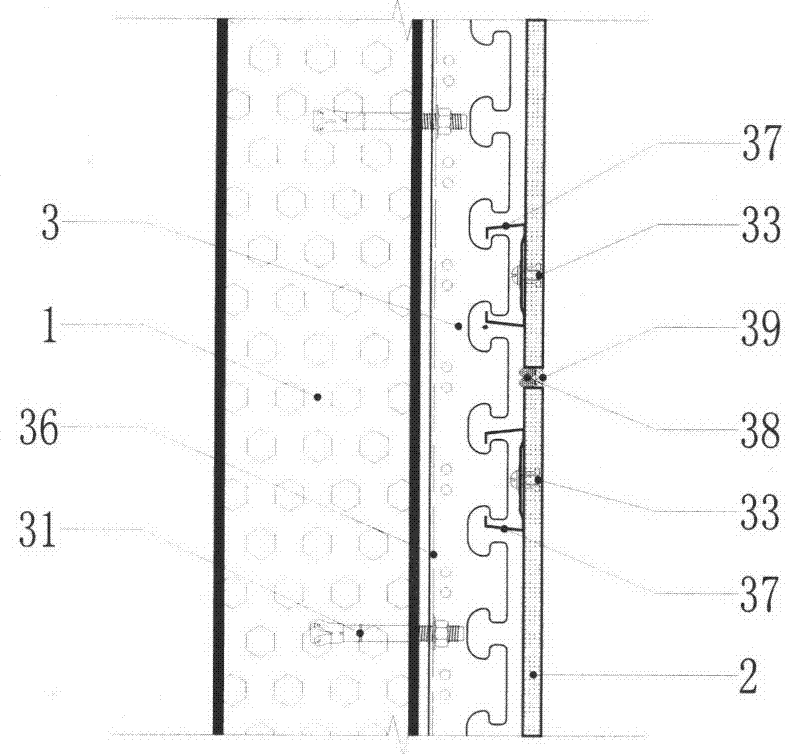

[0044] Reference figure 1 The present invention is a schematic diagram of the structure of an integrated finished wall. The integrated finished wall includes a base wall 1, and the finished wall further includes a decorative panel 2 and a connecting system 3 between them, which are connected as a whole. The connecting system 3 in turn includes a base wall anchoring device 31, a main body connecting device 32, and a decorative panel anchoring device 33. The base wall anchoring device 31 is connected to the base wall 1, the decorative panel anchoring device 33 is connected to the decorative panel 2, and one end of the main body connecting device 32 It is connected with the anchoring device 31 for the foundation wall, and the other end is connected with the anchoring device 33 for the decorative panel. The anchoring device 31 for the base wall and the anchoring device 33 for the decorative panel are mainly anchor bolts, and L-shaped or П-shaped connectors are selected as required, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com