Fluid driving structure high-speed rotating test device for verifying fluid-solid coupling algorithm

A fluid-driven, fluid-structure coupling technology, applied in fluid dynamics tests, testing of machine/structural components, measuring devices, etc., can solve the problems of high production cost, long production cycle, high energy consumption and test cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

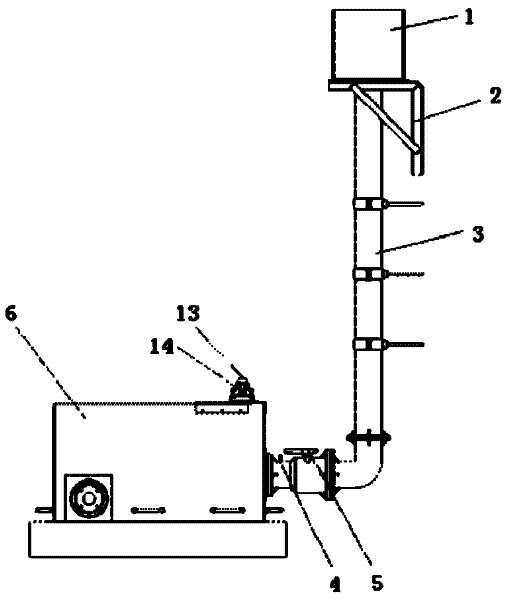

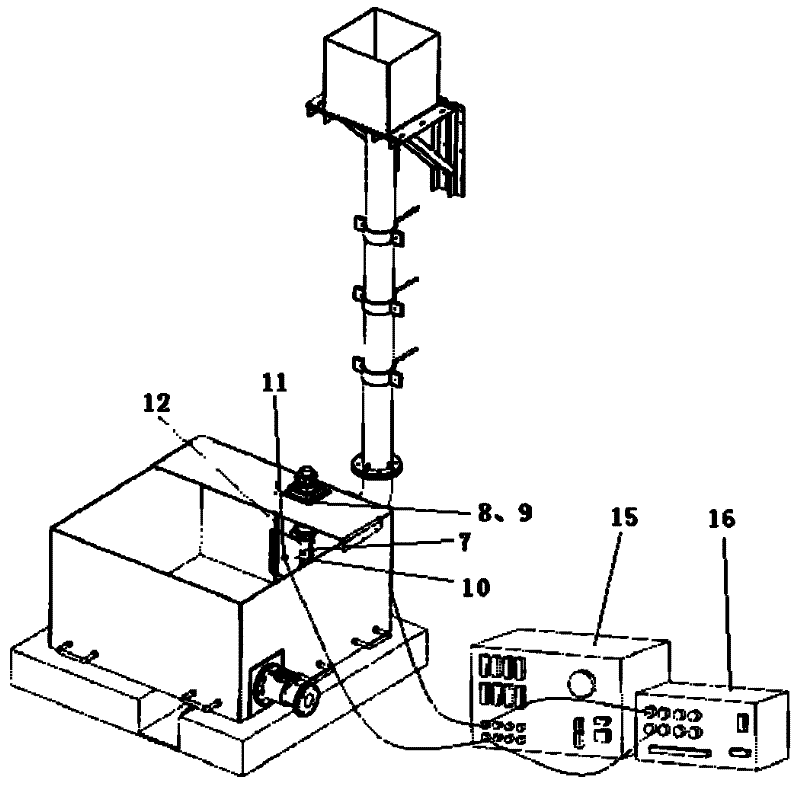

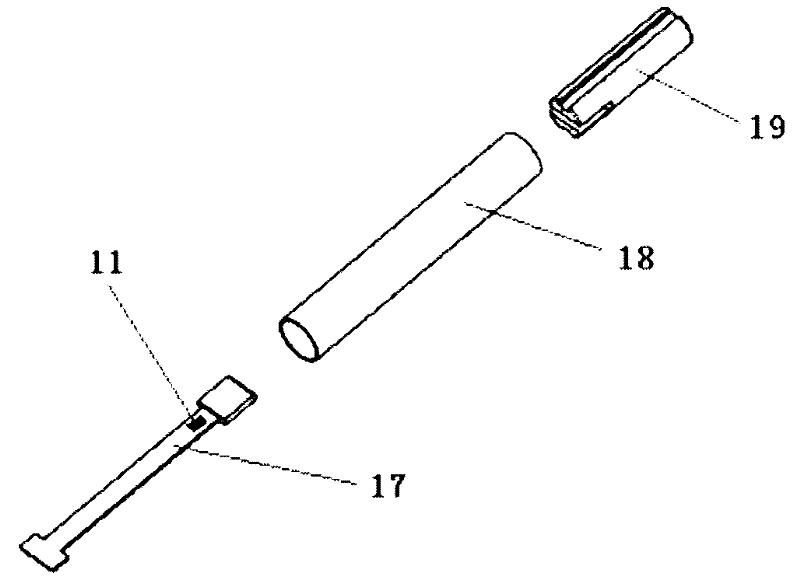

[0048] Below in conjunction with accompanying drawing, the present invention is described in further detail: see accompanying drawing

[0049] See Fig. 1, a fluid-driven structure high-speed rotation test device for verifying the fluid-solid coupling algorithm of the present invention, which includes a water tank 1, a water tank bracket 2, a PVC pipeline 3, a target flowmeter 4, a butterfly valve 5, a water tank 6, and a rotating shaft 7 , bearing 8, bearing seat 9, thin plate 10, strain gauge 11, gear lever 12, angular displacement sensor 13, tight elastic coupling 14, dynamic strain gauge 15 and intelligent signal acquisition and processing analyzer 16. The position connection relationship between them is:

[0050]The water tank 1 is placed on the water tank bracket 2 and placed at the highest point of the device. The bottom of the water tank 1 is connected to one end of the PVC pipeline 3, and the other end of the PVC pipeline 3 is connected to the water inlet on the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com