Full-elemental analysis method for stainless steel sample

An analysis method, an all-element technology, applied in the fields of analyzing materials, material analysis using wave/particle radiation, measuring devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] Example: Using the sample preparation conditions of the milling machine speed of 300r / min and the feed speed of 250mm / min, the surface of the sample for analysis was processed.

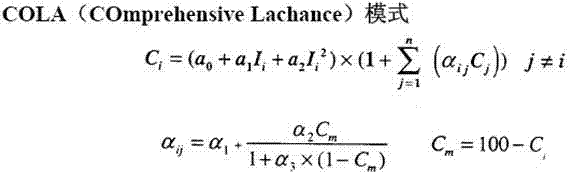

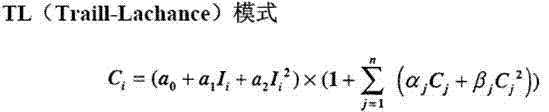

[0014] Put the stainless steel sample processed through the above steps into an X-ray fluorescence analyzer for analysis of chromium, nickel, and iron elements (this analysis process is automatically analyzed by the X-ray fluorescence analyzer), and the tube pressure of the X-ray fluorescence analyzer The tube flow analysis condition is 50kV / 50mA, the fixed channel is used to analyze chromium and nickel elements, and the scanning channel is used to analyze iron-based elements. The analysis time of X-ray fluorescence instrument for chromium, nickel and iron elements is 20 seconds respectively. The working curve, the drawing process of the working curve is a known technology, and will not be described in detail in this embodiment, that is, a series of standard samples will absorb the intensity u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com