Super-flexible cable

A super-flexible, cable technology, applied in the field of power cables, can solve problems such as easy to break, and achieve excellent bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

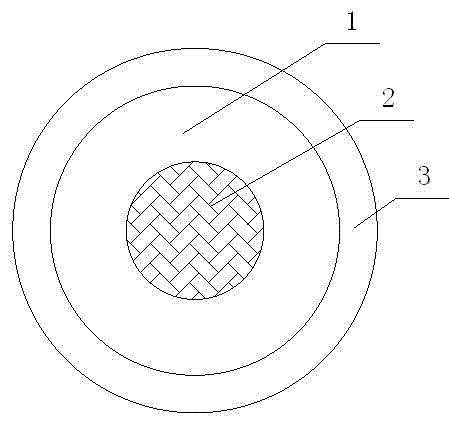

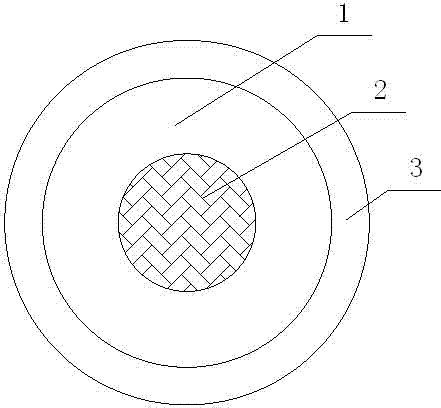

[0013] like figure 1 , an ultra-flexible cable according to the present invention, comprising a cable conductor core 1, placing electrical steel wire, electrical steel wire rope, aramid wire or aramid rope as a reinforcing core 2 in the middle of the cable conductor core 1, The insulating layer 3 is extruded outside the core. The conductive core is braided with copper strands around the reinforcing core using a braiding machine. The diameter of steel wire for electrician is 0.20~1.0mm, the diameter of steel wire rope for electrician is 1.0~5.0mm, and the tensile strength is between 850~1550Mpa. The diameter of the aramid yarn is 0.20-1.0mm, and the diameter of the aramid rope is 1.0-5.0mm.

[0014] In the present invention, a high-strength thin steel wire (rope) for electrician is placed in the middle of the cable conductor core, and aramid fiber (rope) is used as a reinforcing core, and copper strands are used to weave around the reinforcing core by a braiding machine to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com