Ultra-soft and burn-resistant communication cable for robot welding gun

A technology for communication cables and robots, which is applied in communication cables, insulated cables, bendable cables, etc. It can solve the problems of short service life of cables, hard cores of communication cables, and difficulty in installation, etc., and achieve protective shielding effect and good shielding effect , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below through embodiments in conjunction with the accompanying drawings.

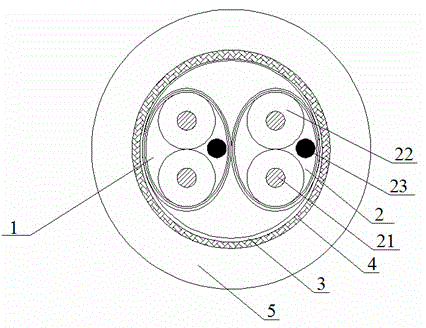

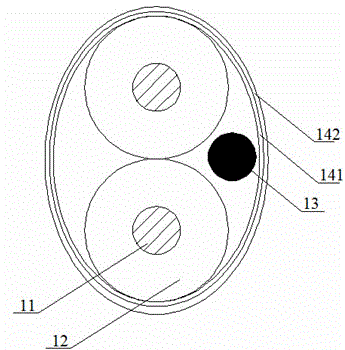

[0022] A communication cable for a super-flexible scald-resistant robot welding gun, comprising a power line 1, a signal line 2, a non-woven fabric 3, a metal shielding layer 4 and an insulating sheath 5. The power line 1 is sequentially composed of the multi-core conductor 11 of the power line, the polyvinyl chloride insulation 12 of the power line, the ground wire 13 of the power line, and the shielding insulation layer 14 of the power line from the inside to the outside; From inside to outside, there are multi-core conductors 21 of signal lines, foamed PE insulation 22 of signal lines, ground wires 23 of signal lines and shielding insulation layer 24 of signal lines. The multi-core conductors 11 and 21 of the power line and the signal line are all composed of a plurality of tinned copper wires with a single wire diameter of 0.05-0.15 mm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com