Crop straw filament-rubbing machine

A crop straw and silk machine technology, applied in the direction of grain processing, etc., can solve the problems of incomplete crushing, unevenness, failure to meet the use requirements, etc., and achieve the effect of uniform and thorough crushing, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

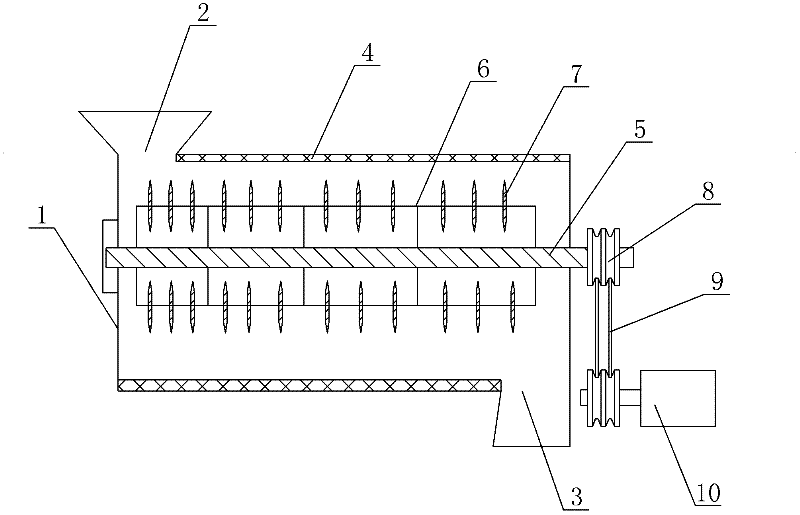

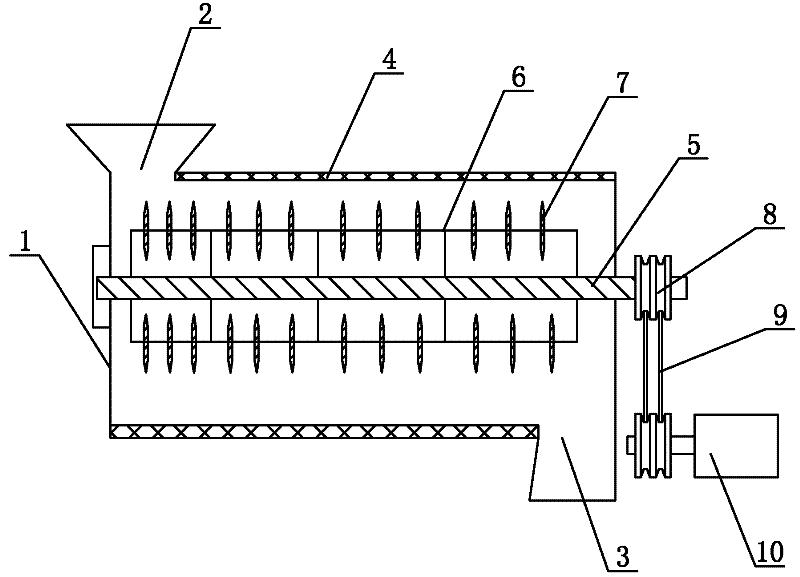

[0015] Please refer to figure 1 as shown, figure 1 It is a cross-sectional view of the crop straw kneading machine of the present invention; in this embodiment, a crop straw kneading machine includes a chassis 1, a crushing cutter, a power unit, a feed port 2 and a discharge port 3, and the feed port 2 It is opened on the top of the cabinet 1 , and the discharge port 3 is opened on the bottom of the cabinet 1 . The casing 1 is equipped with a rotating shaft 5 that runs through the entire casing 1, and the rotating shaft 5 is rotatably mounted on the casing 1, and one end of the rotating shaft 5 is equipped with a transmission wheel 8, and the transmission wheel 8 passes through a transmission belt 9 Connect the servo motor 10, a crushing tool is installed on the rotating shaft 5, and the crushing tool includes a cylindrical knife holder 6, a plurality of blunt blades 7 are uniformly distributed on the knife holder 6, and the inner wall 4 of the cabinet is corrugated shape. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com