Geometric parameter measuring method for vertical shaft

A measurement method and a technology of geometric parameters, which are applied in the field of borehole diameter detection and well deviation limit value, can solve the problems that the ultrasonic ranging circuit cannot meet the measurement requirements, the measurement environment cannot have ferromagnetic substances, and the attenuation fluctuation of high-frequency ultrasonic waves is large. , to achieve simple and effective technical effects, highlighting technological progress, and suppressing echo interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

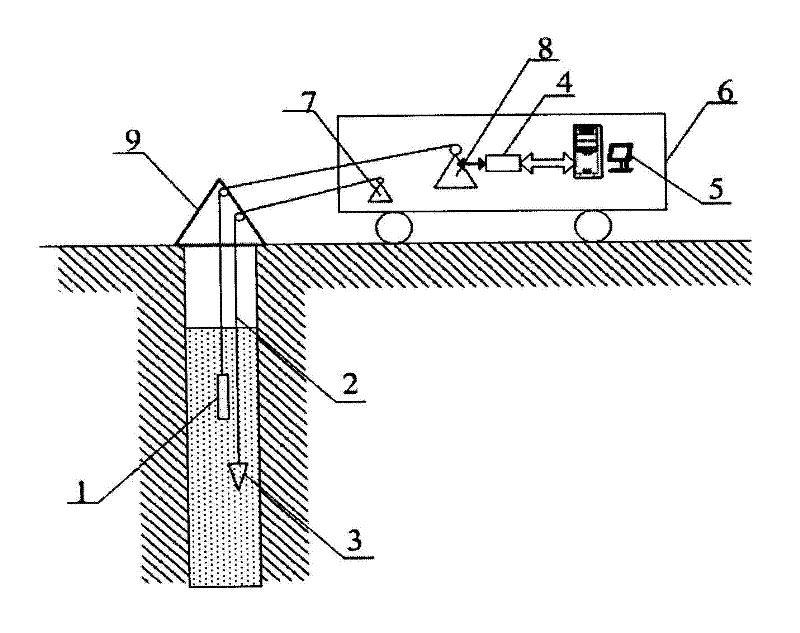

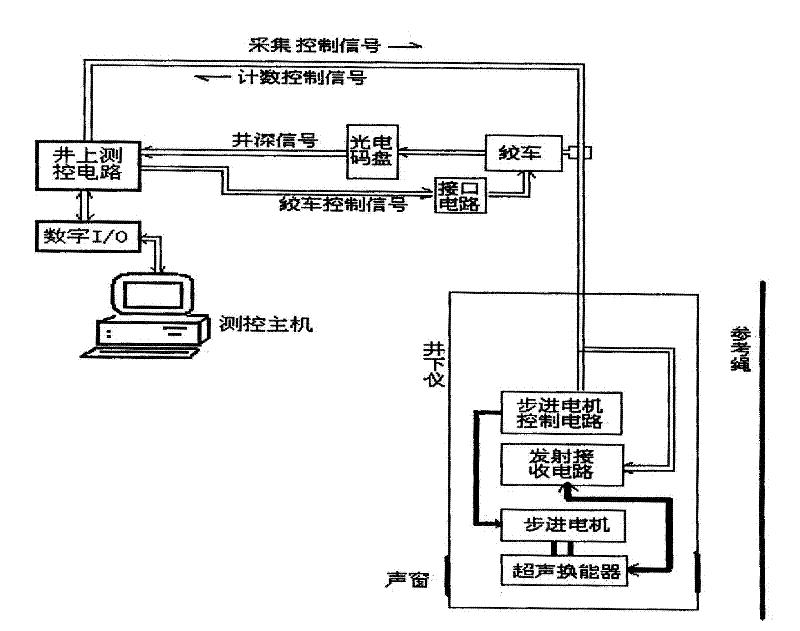

[0029] Implementation plan: the reference rope method is adopted, and the downhole instrument 1 and the reference rope 2 are arranged on the support 9 at the wellhead; the downhole instrument 1 is connected with the built-in cable winch 8 of the instrument car 6 and the computer 5 interface of the uphole instrument 4, and its measurement is recorded. Data; it is connected with the reference rope 2 of the heavy hammer 3 and the built-in reference rope winch 7 of the instrument car 6 to control its lifting; the measurement is implemented step by step;

[0030] ① Designed for a water-bearing vertical shaft with a depth of 900 meters and a diameter of 2.5 meters. The underground water pressure is high, the water quality is turbid, and the water temperature changes greatly;

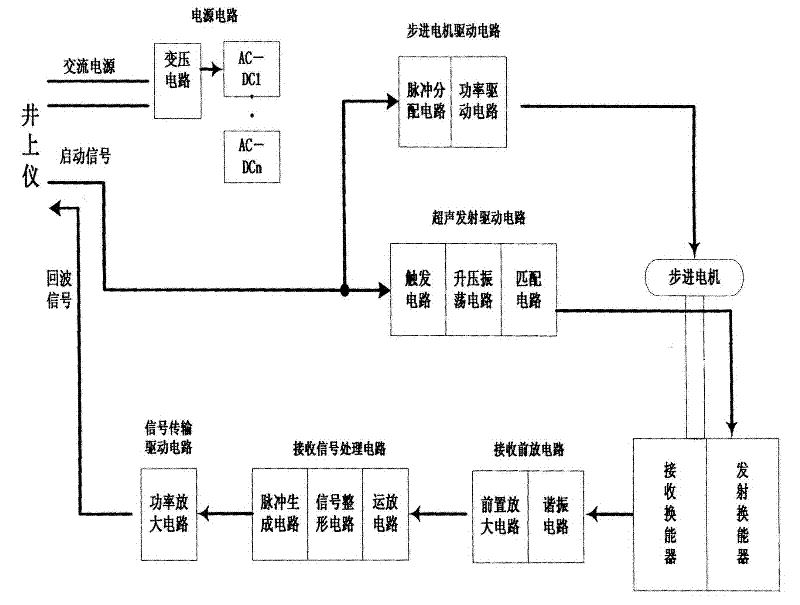

[0031] ②The design adopts a separate structure, which is divided into an upper-hole tool 4 and a down-hole tool 1. The upper-hole tool 4 and the down-hole tool 1 are connected by an armored 4-core twisted-pair ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com