Design method of stretch bending loading trace of novel stretch bender

A technology of loading trajectory and design method, which is applied in the design field of the tensile-bending loading trajectory of a new type of tension-bending machine, can solve the public report of the design method of the loading trajectory of the stretching-bending process that is not found, and affect the dimensional accuracy and strain of profile parts. Non-uniformity and other problems, to avoid uneven distribution of stretch, improve uniformity, and improve dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

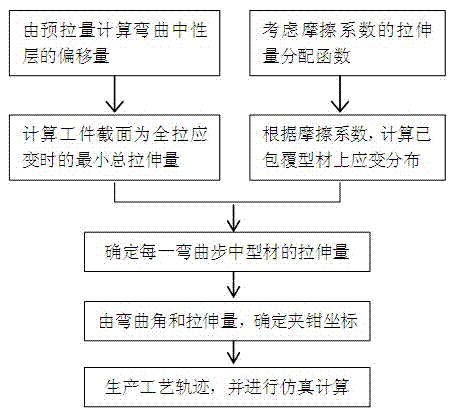

[0048] In this embodiment, an L-shaped aluminum alloy profile with a length of 2750mm is adopted, according to figure 1 Generate the loading trajectory of the profile stretch bending process, which specifically includes the following steps:

[0049] first step:

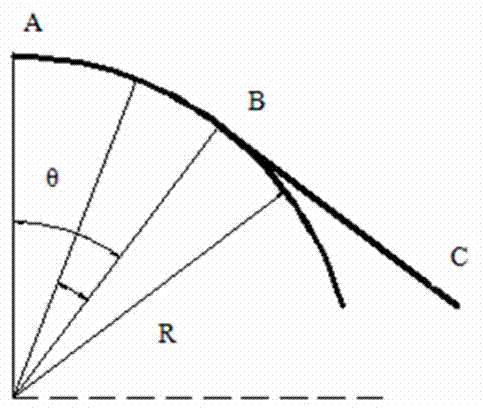

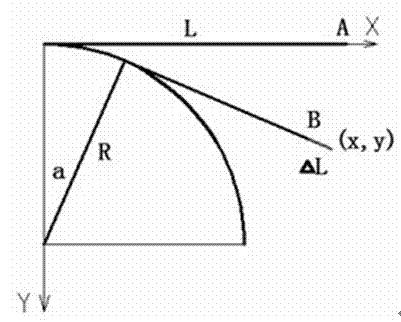

[0050] Regulation: is the pre-stretch amount, is the profile length, is the distance between the strain neutral layer and the lower surface when the profile is purely bent, is the bending radius of the profile, Offset to bring the neutral layer down for pre-pull, is the strain induced by the pretension, is the pure bending internal strain, is the distance from the lower surface of the profile to the strain-neutral layer after offset, is the angle of bend for each step, is the angle covered by the nth step, The bending angle is necessary to finish molding, is the length of the profile after the nth step of bending, is the total length of the contact part between the profile and the mold after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com