Plasma transfer wire arc thermal spray system

A plasma and transfer arc technology, applied in the direction of plasma, injection device, liquid injection device, etc., can solve the problems of high machine and operation cost, undesigned, etc., and achieve the effects of prolonged nozzle life, easy start-up and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

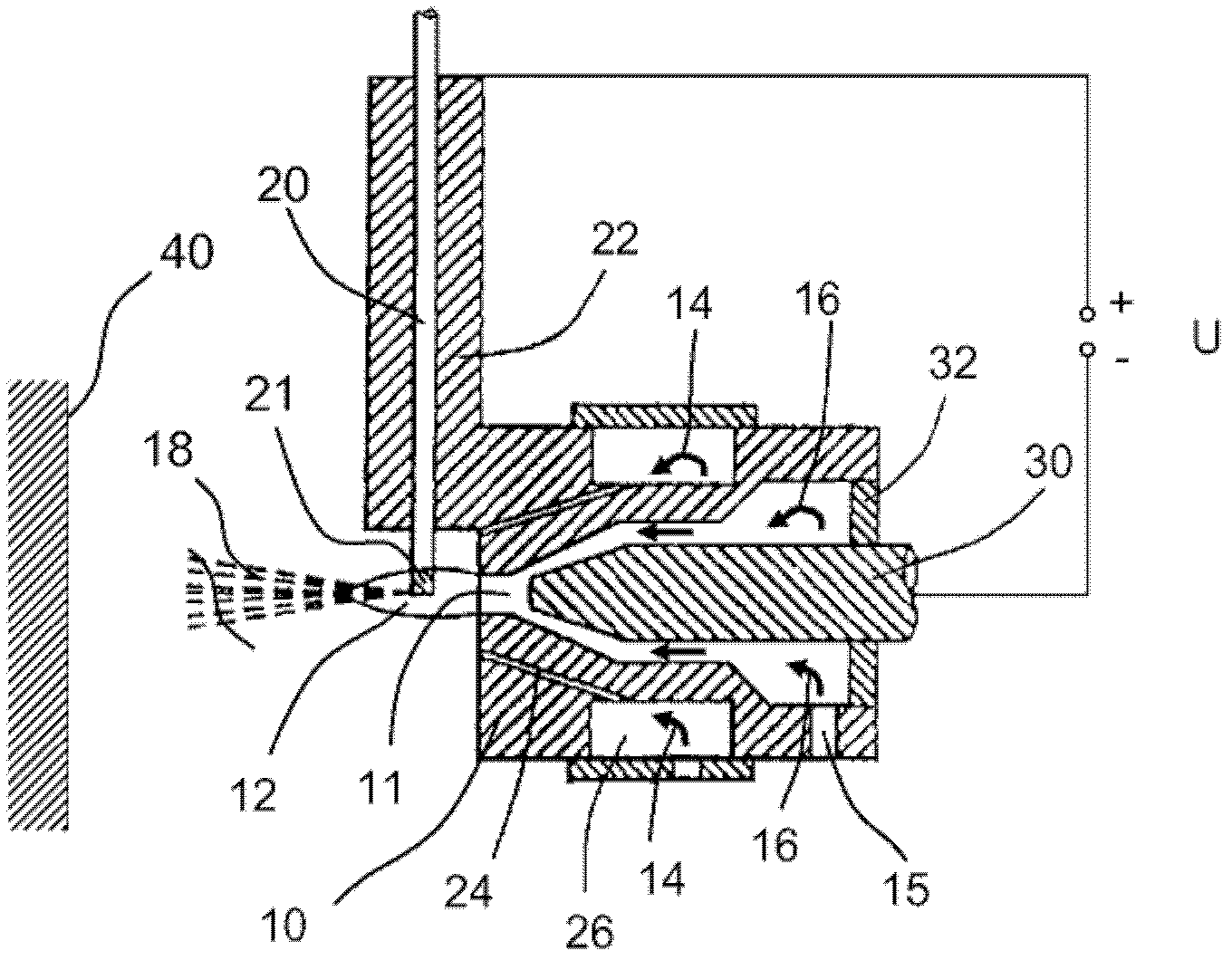

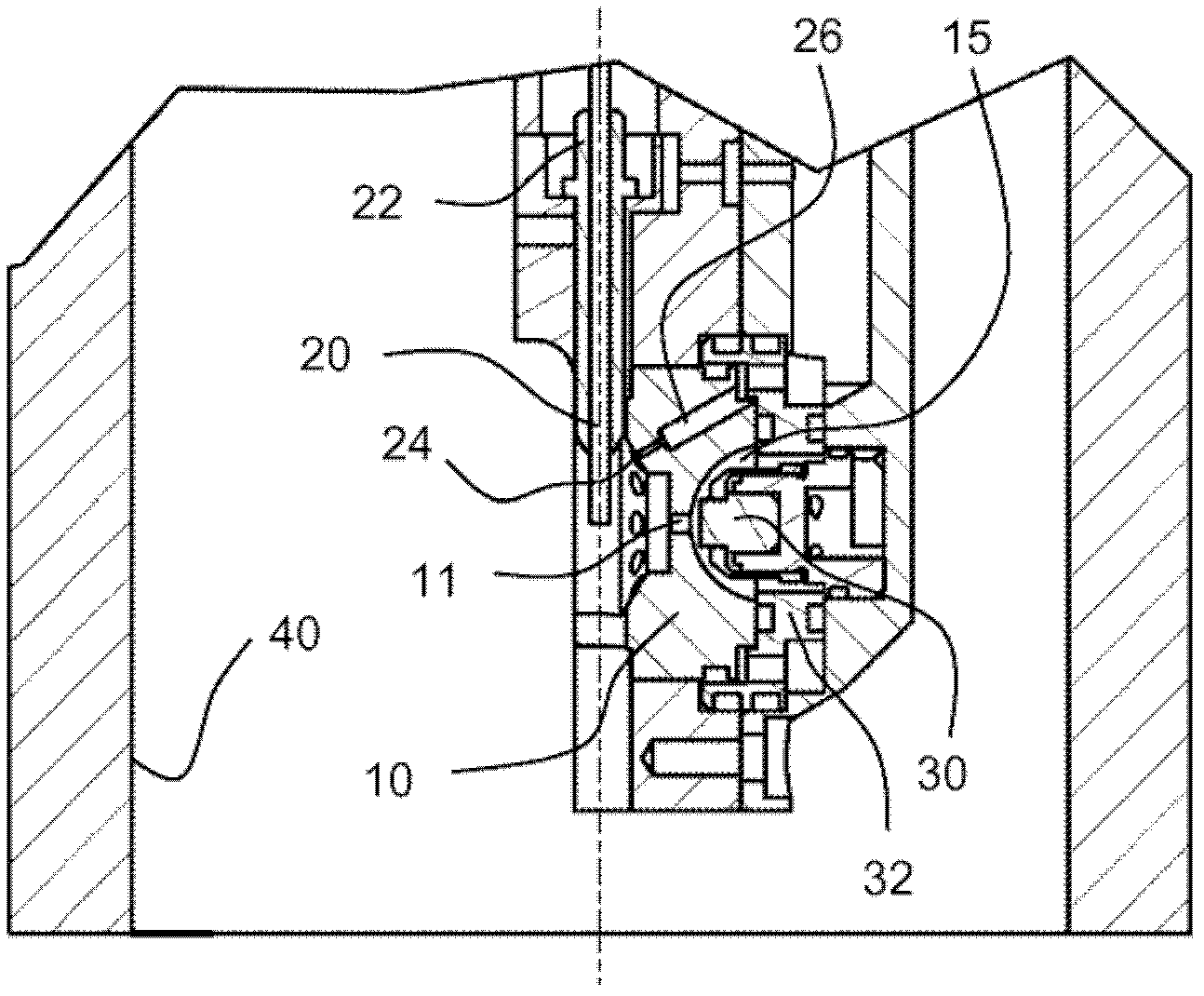

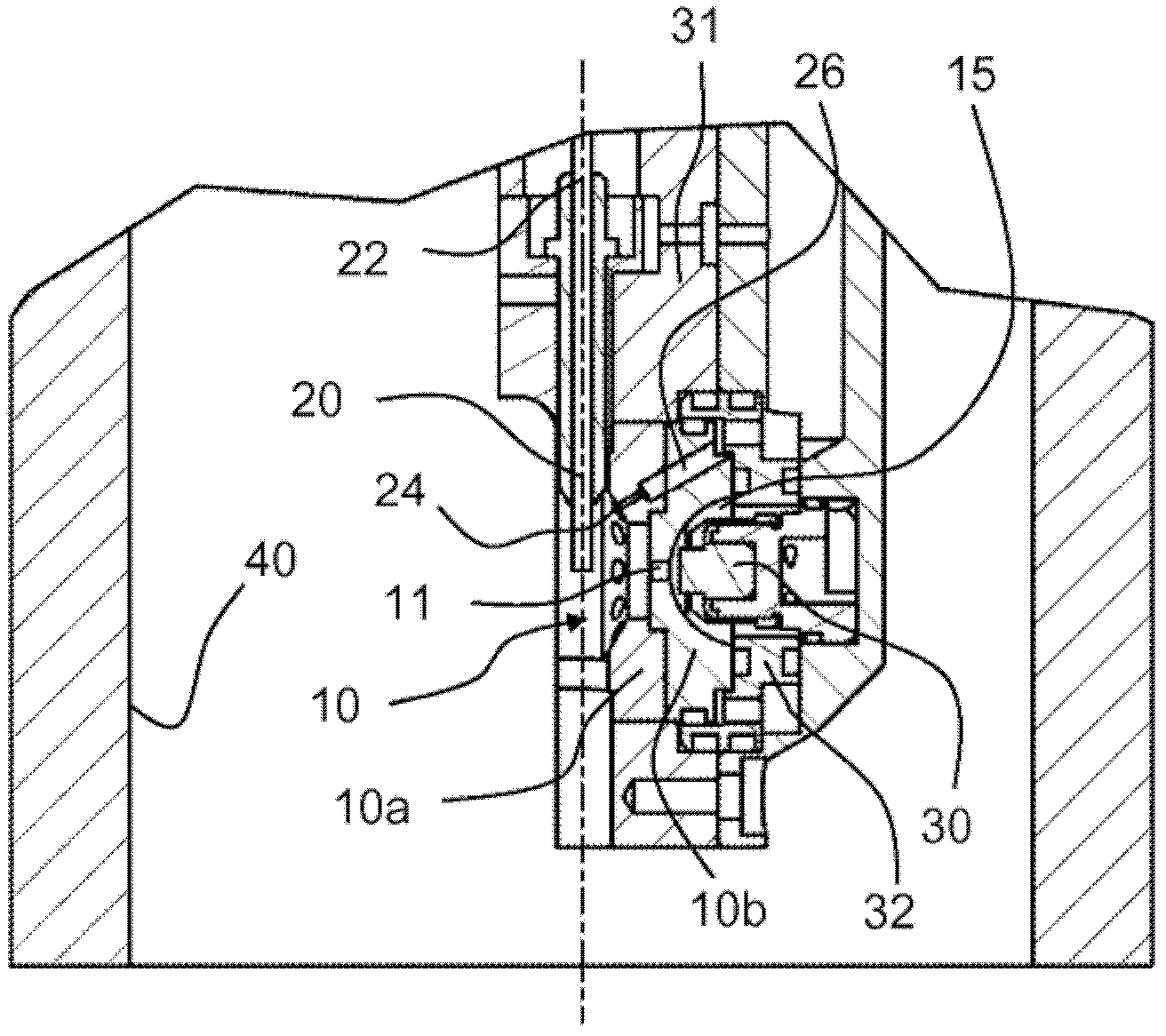

[0058] Reference will now be made in detail to presently preferred combinations or embodiments and methods of the invention, which constitute the best modes of carrying out the invention currently known to the inventors. In one embodiment of the present invention, an improved PTWA spray gun is provided. The spray gun of the present invention is a component in a plasma wire transferred arc thermal spray apparatus that can be used to spray a surface with a dense metallic coating. The torch of the present invention comprises a wire feed guide having a wire feed guide for supplying wire into the plasma flame, an auxiliary gas portion for providing auxiliary gas surrounding the plasma formed by the plasma flame, and Assembly of the nozzle portion of the formed plasma.

[0059] refer to figure 1 , shows a schematic of the thermal spray process. In thermal spraying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com