Water-saving type filtration tank

A filter pool, water-saving technology, applied in the direction of filtration separation, gravity filter, fixed filter element filter, etc., can solve the problems of complex operation management, short filtration cycle, and many reverse times, so as to extend the filtration cycle, The effect of reducing the water consumption of backwashing and reducing the frequency of sludge discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

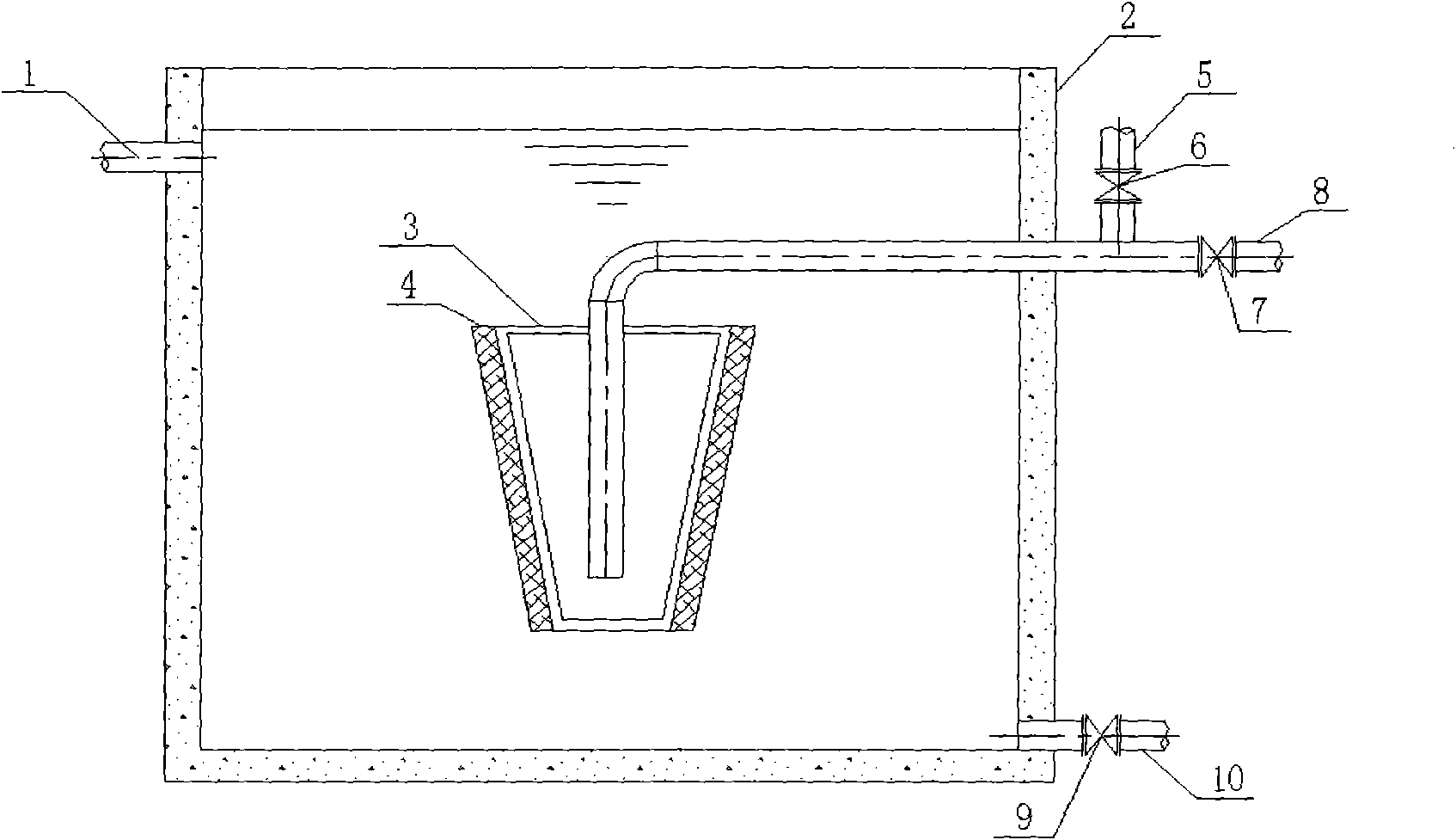

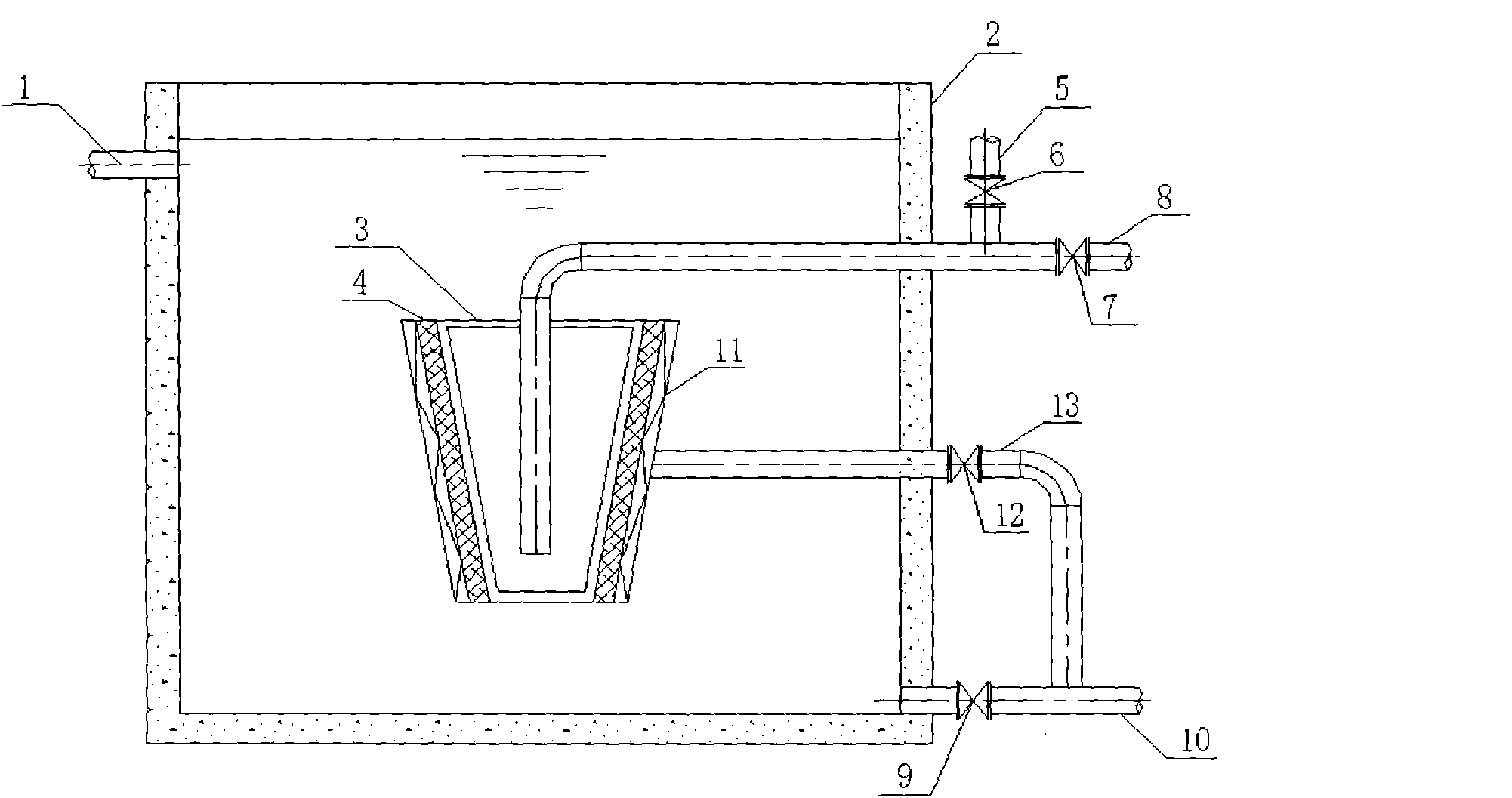

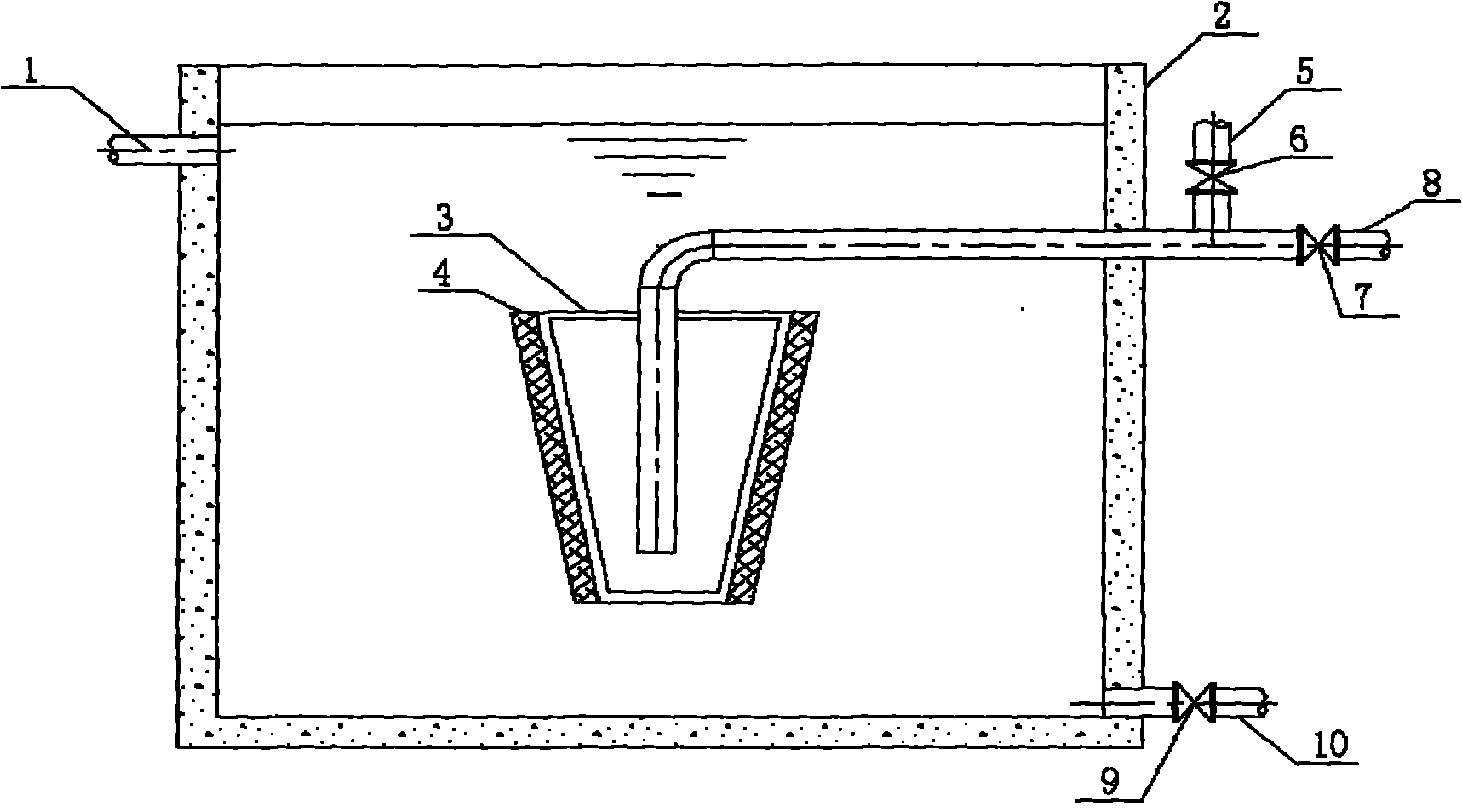

[0011] exist figure 1 Among them, the water-saving filter tank is mainly composed of water inlet (1), tank body (2), filter material support (3), filter material (4), backwash pipe (5), backwash valve (6), water outlet A valve (7), a water outlet (8), a mud discharge valve (9), and a mud discharge port (10) are formed, and the filter material support (3) and the filter material (4) are combined to form a filter unit. The filter unit is connected to the backwash pipe (5) and the water outlet (8) through pipelines; the water inlet (1) and the mud discharge outlet (10) are connected to the tank body (2), and the water to be filtered flows in from the water inlet (1) In the pool body (2), the sediment is discharged from the bottom of the pool body (2) through the mud discharge port (10) controlled by the mud discharge valve (9). The filter unit is placed in the water of the pool body (2), and the filter unit is of a thin bottom and thick top structure, and multiple filter units c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com