Catalyst components for olefin polymerization and catalyst thereof

A technology for olefin polymerization and catalysts, which is applied in the field of catalyst components and catalysts for olefin polymerization reactions, and can solve problems such as different binding abilities, catalyst performance effects, and different content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

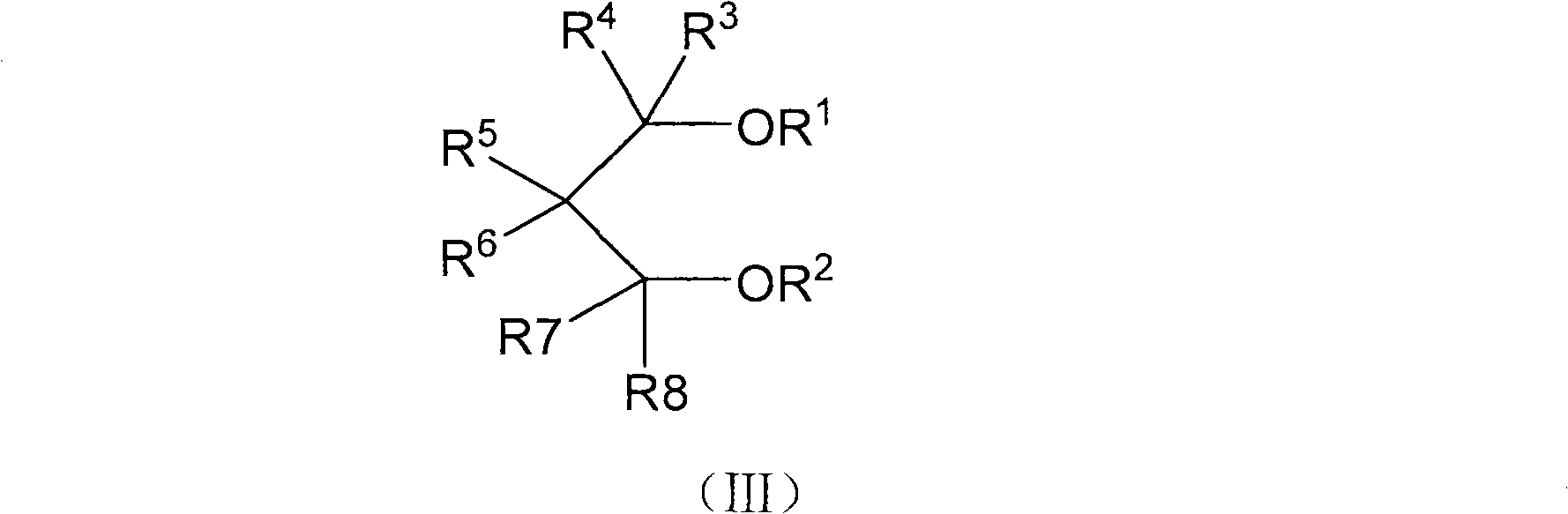

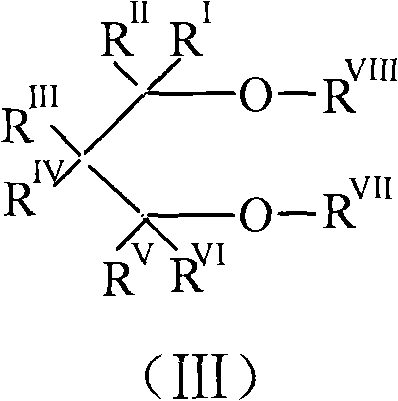

Method used

Image

Examples

preparation example Construction

[0061] 1. Preparation of the compound

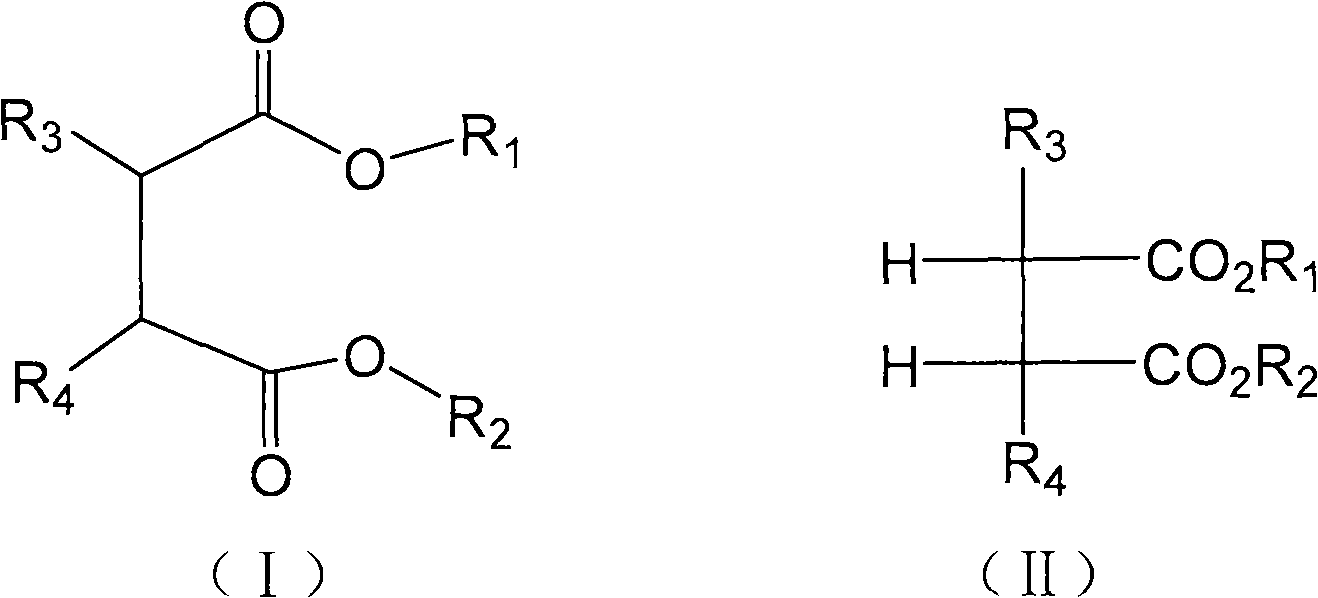

[0062] Synthesis of succinate compound (I): Synthesis was carried out according to the method described in Journal of Polymer Science: Polymer Chemistry Edition. 1980 (18), 1739-1758 (authors are A. Yamada, S. Grossman and O. Vogl).

[0063] The general procedure is as follows.

[0064] (1) Synthesis of succinate compound (I)

[0065] Add freshly steamed 1.2L THF into a 3L flask with stirring, reflux condenser and dripping device, and add 134g (0.99mmol) of anhydrous CuCl under vigorous stirring 2 . When brown CuCl 2 After the powder becomes orange-red crystals, add 64g (0.98mol) of activated zinc powder and a small amount of HgBr 2 , And then add 100g (0.48mol) ethyl 2-bromoisovalerate dropwise, and heat to reflux for 2h after the addition. Let it settle overnight at room temperature.

[0066] Pour out the clear solution, remove THF under reduced pressure on a rotary evaporator, and pour the remaining liquid into a separatory funnel. The solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com