Engine rail press precontrol and feedback control device as well as control system and control method

A feedback control and control system technology, applied in engine control, machine/engine, electrical control, etc., can solve problems such as difficult to quickly and accurately follow the target current, large difference in ambient temperature of the control valve, and slow response of current following control. Achieve optimal software resources, reduce difficulty and complexity, and have good followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

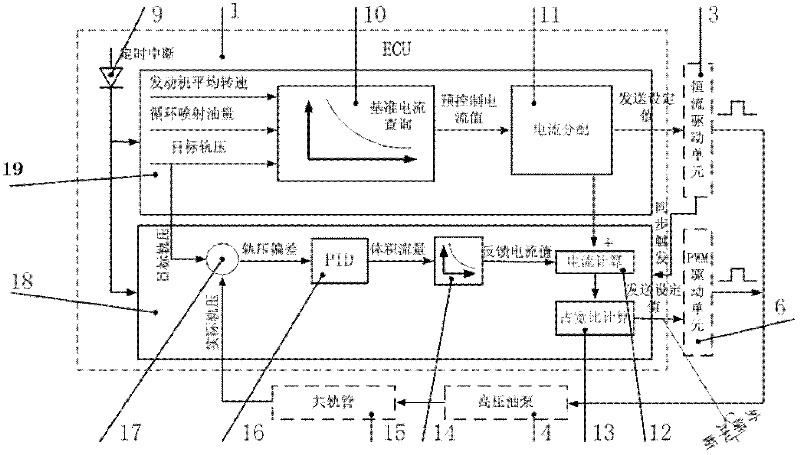

[0038]The engine rail pressure pre-control and feedback control device, control system and control method of the present invention will be described in detail below in conjunction with the embodiments and drawings.

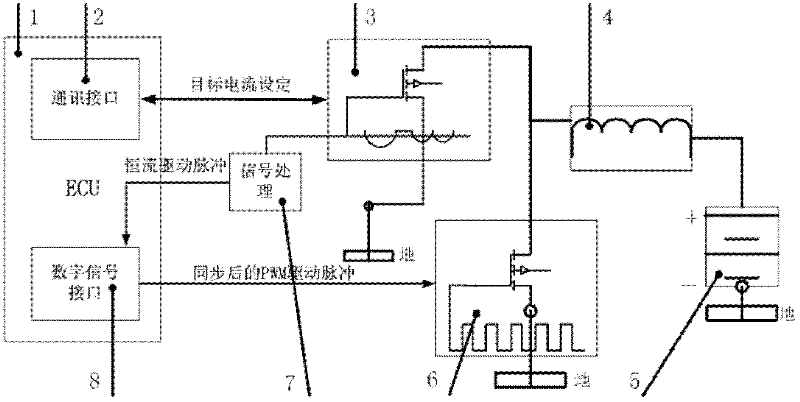

[0039] The engine rail pressure pre-control and feedback control device, control system and control method of the present invention are mainly composed of hardware parts (such as figure 1 shown) and software parts (such as figure 2 shown) composition.

[0040] The hardware part The engine rail pressure pre-control and feedback control device of the present invention is mainly used to provide the operating platform of the software part to realize the current management of the high-pressure oil pump oil quantity metering unit 4, which mainly includes an ECU unit 1 and a constant current control unit 3 And PWM drive unit 6 three parts.

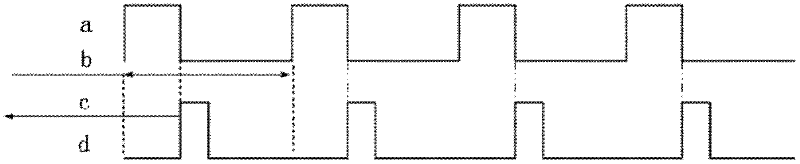

[0041] Such as figure 1 As shown, the engine rail pressure pre-control and feedback control device of the present invention inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com