Self-sensing piezoelectric diaphragm pump

A diaphragm pump, self-sensing technology, applied in the direction of pumps, pump control, pumps with flexible working elements, etc., can solve the problems that hinder the popularization and application of piezoelectric diaphragm pumps, increase the cost of use, increase the volume, weight and complexity of the system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

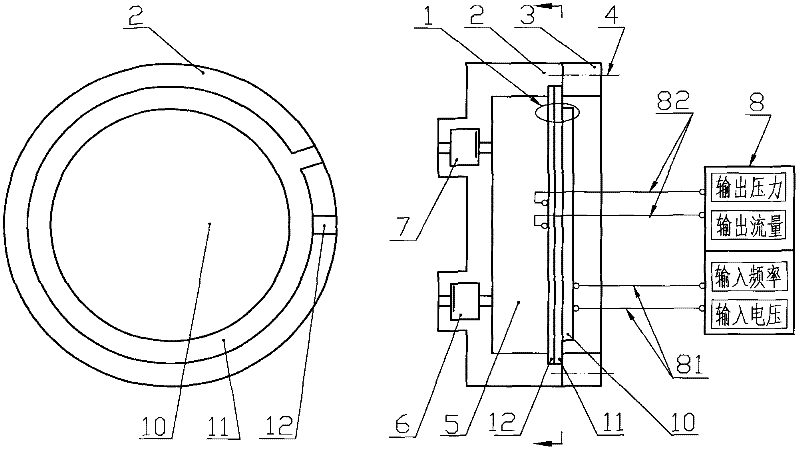

[0011] Such as figure 1 As shown, the composite sheet piezoelectric vibrator 1 is installed inside the pump body 2 and clamped by the pump cover 3; the pump body 2 and the pump cover 3 are connected by screws 4; the pump body 2 is equipped with an inlet The valve 6 and the outlet valve 7 ; the piezoelectric vibrator 1 , the pump body 2 , the inlet valve 6 and the outlet valve 7 together constitute the pump chamber 5 . The composite sheet piezoelectric vibrator 1 is formed by bonding a PZT piezoelectric wafer driver 10, a metal substrate 11 and a PVDF piezoelectric film sensor 12; The wire group 82 is connected with the control power supply 8 .

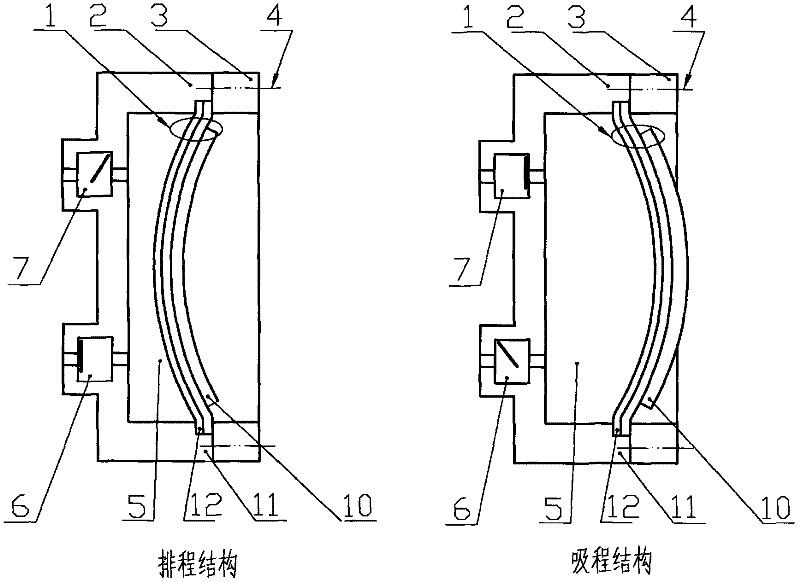

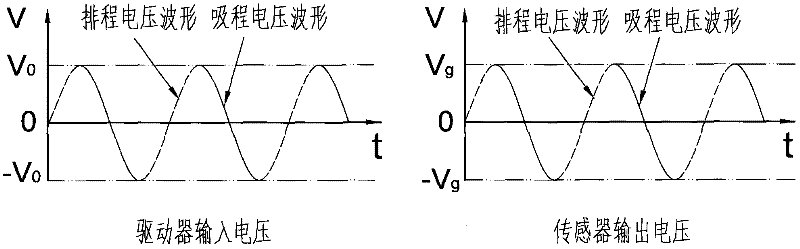

[0012] Such as figure 2 , image 3 As shown, when the control power supply 8 is turned on and enters steady-state operation, the piezoelectric driver 10 is subjected to a voltage (input voltage-V 0 →0→V 0 ) acts to bend the piezoelectric vibrator 1 toward the inside of the pump chamber 5, thereby reducing the volume of the pump c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com