Energy-saving, environment-friendly, easy-dusting, air-heated civil boiler

An energy-saving, environmentally friendly, gas-heating technology, applied in the boiler field, can solve the problems of slow hot and cold air flow, low service life of water heaters, waste of water resources, etc., achieve full absorption and utilization, coordinate indoor layout, and improve air circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

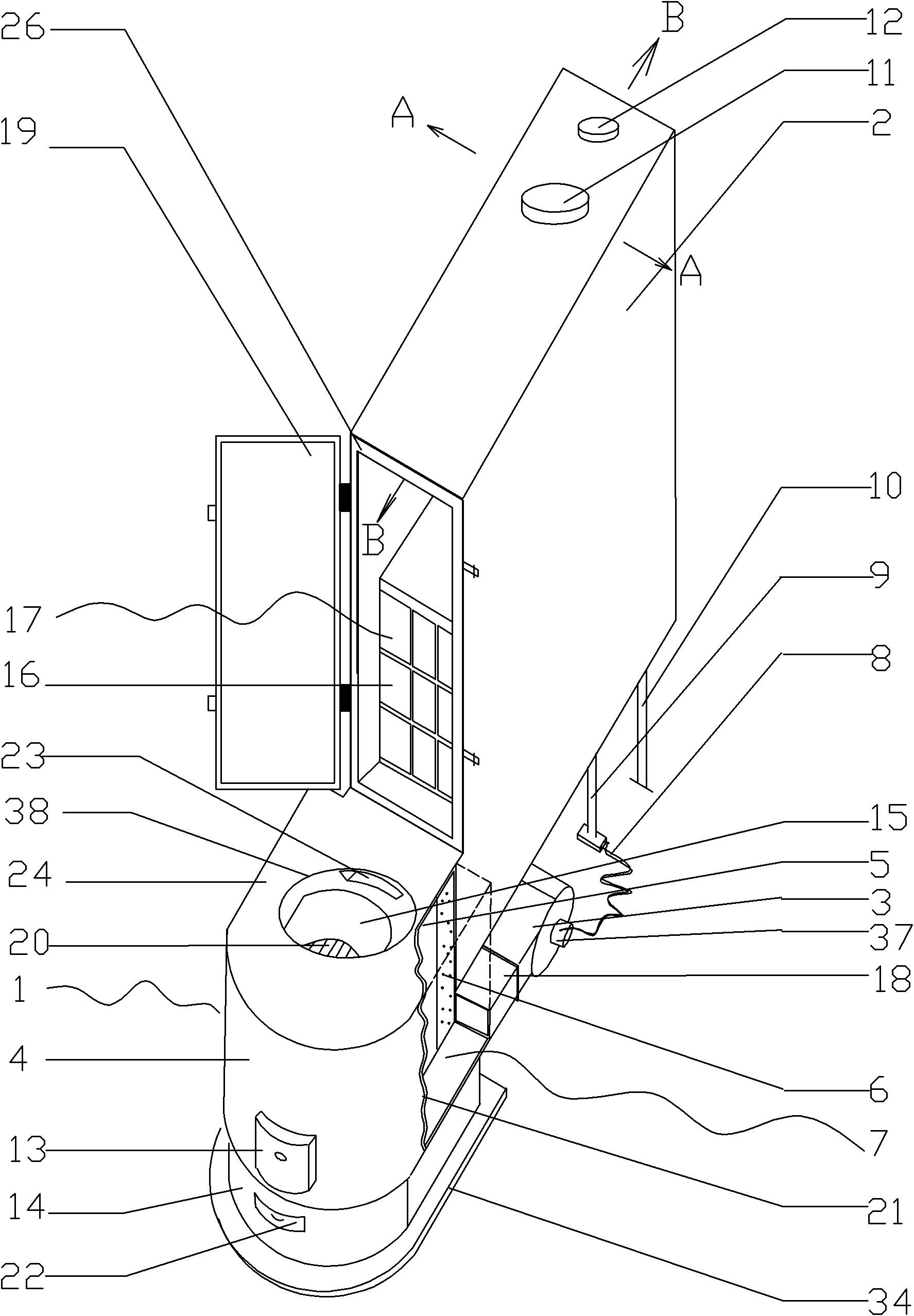

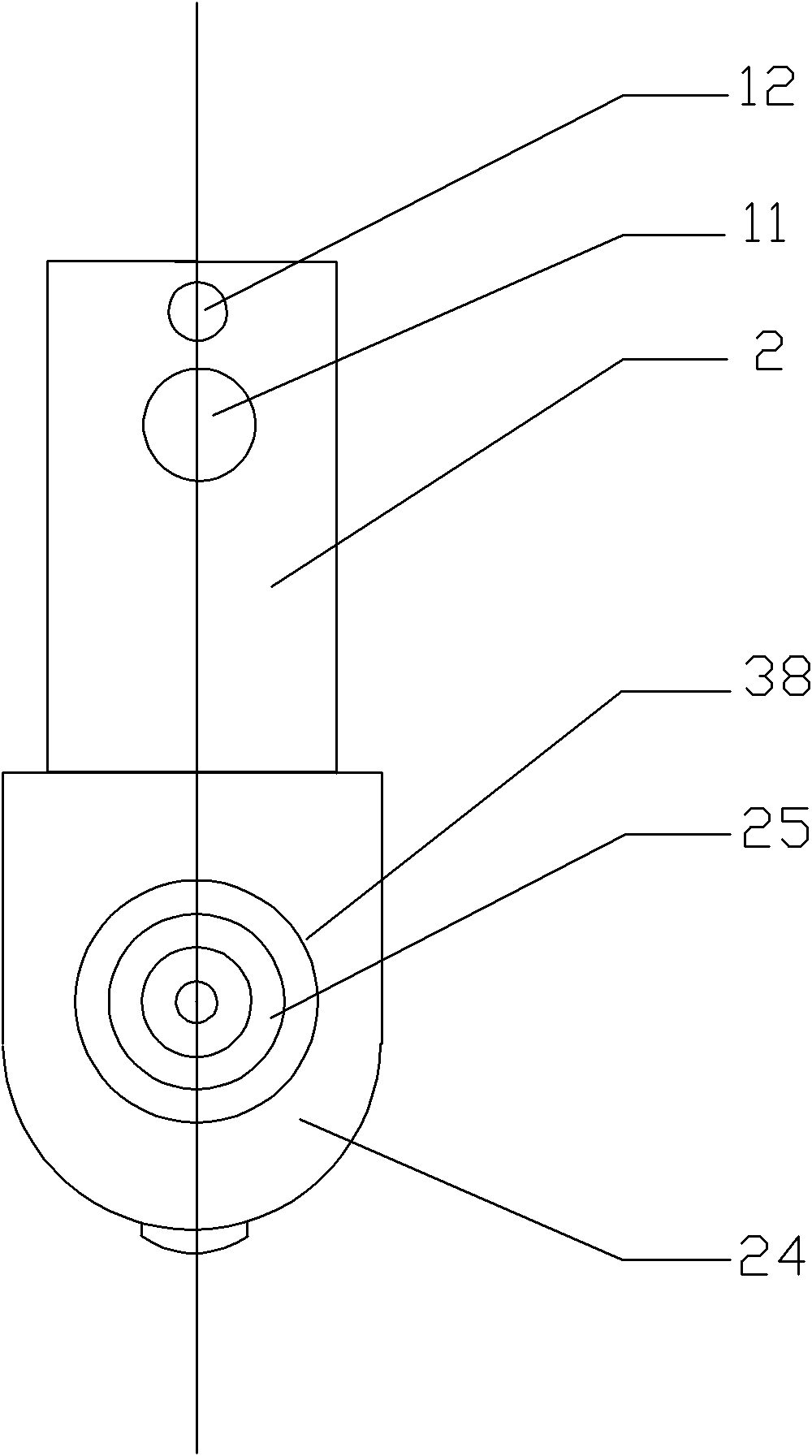

[0043] Such as figure 1 The gas-heated boiler shown includes a furnace 1, a flue 2 and an air supply device. The lower part of the furnace body 4 of the furnace 1 is welded with a support body 14 , the support body 14 is welded on the base 34 , and the drawer 22 for charging coal ash is located on the support body 14 . A U-shaped shell 7 with an interlayer surrounds the furnace body 4. The U-shaped structure can reduce air resistance. The shell 7 includes an inner shell 5 and an outer shell 21. The inner cavity of the furnace body 4 is a furnace 15. , the middle of the bottom of the furnace 15 is provided with a fire grate 20, the upper part of the inner side wall of the housing 7 has a flue through hole 23, the flue through hole 23 communicates with the flue 2, and the outer side wall of the housing 7 is provided with a furnace door 13. The upper part of the casing 7 is provided with a port 38, which is used to add coal. to combine figure 2As shown, the upper surface of t...

Embodiment 2

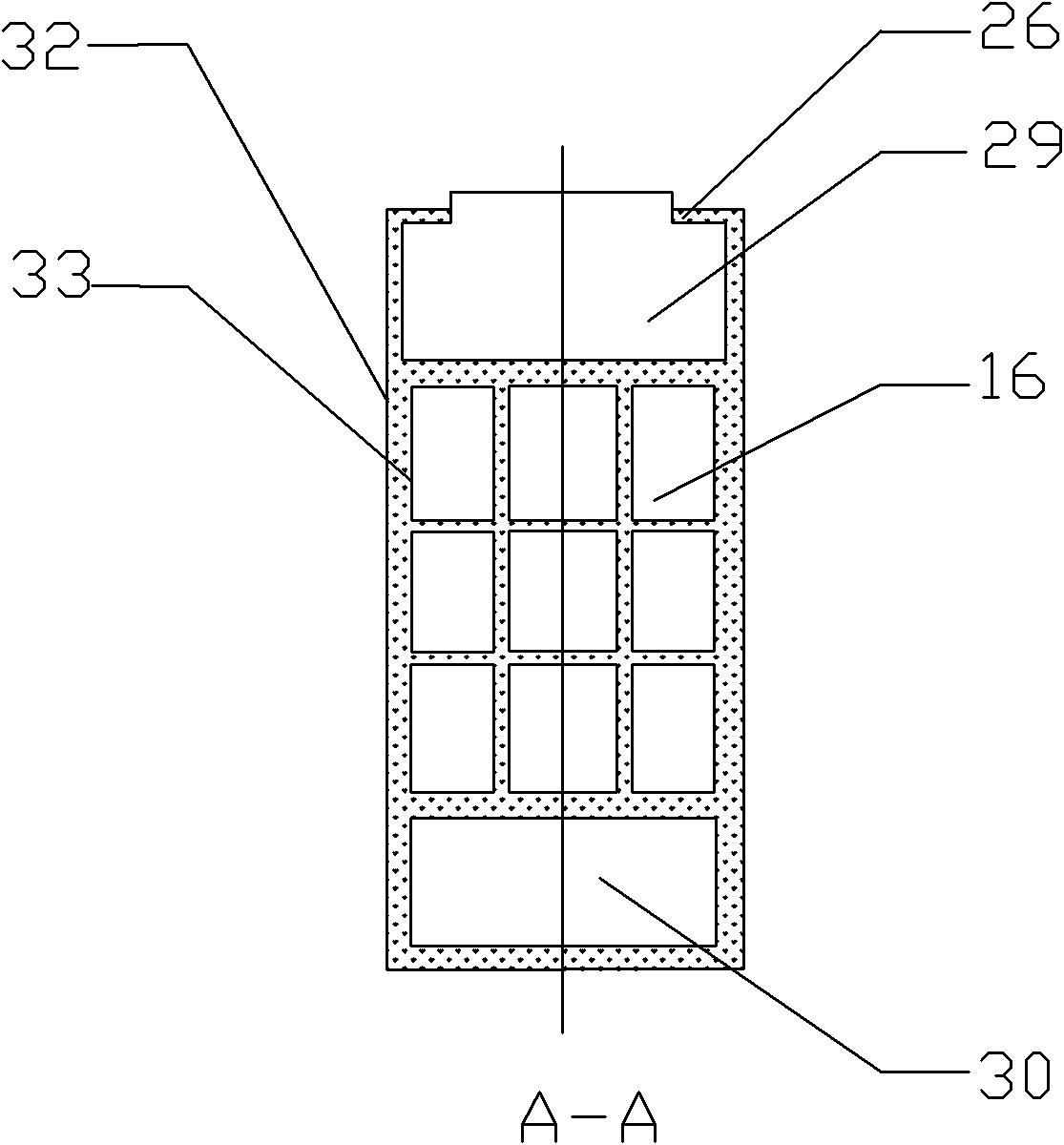

[0050] This embodiment is basically the same as the gas-heated boiler of Embodiment 1, the difference is that the smoke pipe 216 of the smoke part 17 adopts a finned tube structure, as shown in the attached Figure 5 As shown, several fins 241 are disposed on the flue pipe 216 . The specific processing steps of the smoke ventilation parts are as follows. There are 15 parallel flat plates with 9 rectangular holes symmetrically opened, such as Figure 4 As shown, nine flue pipes 216 respectively pass through the rectangular holes, and the ends are respectively lapped on the rectangular holes of the flat plates at both ends. After measurement, the heat dissipation per extended meter of a 1-inch ordinary tube is only equivalent to 0.763 times the heat dissipation of a finned tube.

Embodiment 3

[0052] Such as Figure 7-9 As shown, it is another gas-heated boiler of the present invention. The difference from Embodiment 1 is that in the upper cavity 29 of the flue 2, a smoke-through part 317' is added, and the gas from the middle cavity 331 The high-heat flue gas exchanges its heat more fully through the two flue-through parts 317 and 317'. Correspondingly, two flue doors 319, 319' are provided on the front side of the flue wall 326.

[0053] The gas-heated boiler in this embodiment is 1800 mm high, 550 mm wide, and 1000 mm long, and the air volume of the fan is 5.5 m 3 / min, heating surface thermal power 45000-70000kJ / m 2 ·Hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com