Sintering flue gas desulfurization and purification method and equipment

A technology for sintering flue gas and flue gas, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve problems such as desulfurization of sintering flue gas, achieve high desulfurization efficiency, simple system, and low running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the drawings:

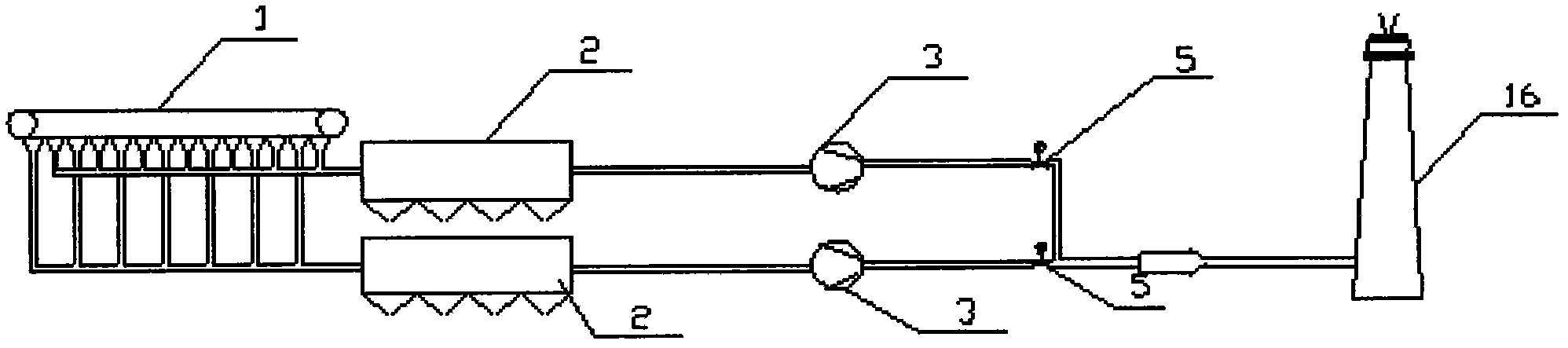

[0049] Such as figure 1 As shown, the original production process is as follows: after the machine head flue gas from the sintering machine 1 is purified by the electrostatic precipitator 2, it is drawn by the sintering main exhaust fan 3 through the flue and discharged into the sintering main chimney 16 through the outlet baffle valve 5.

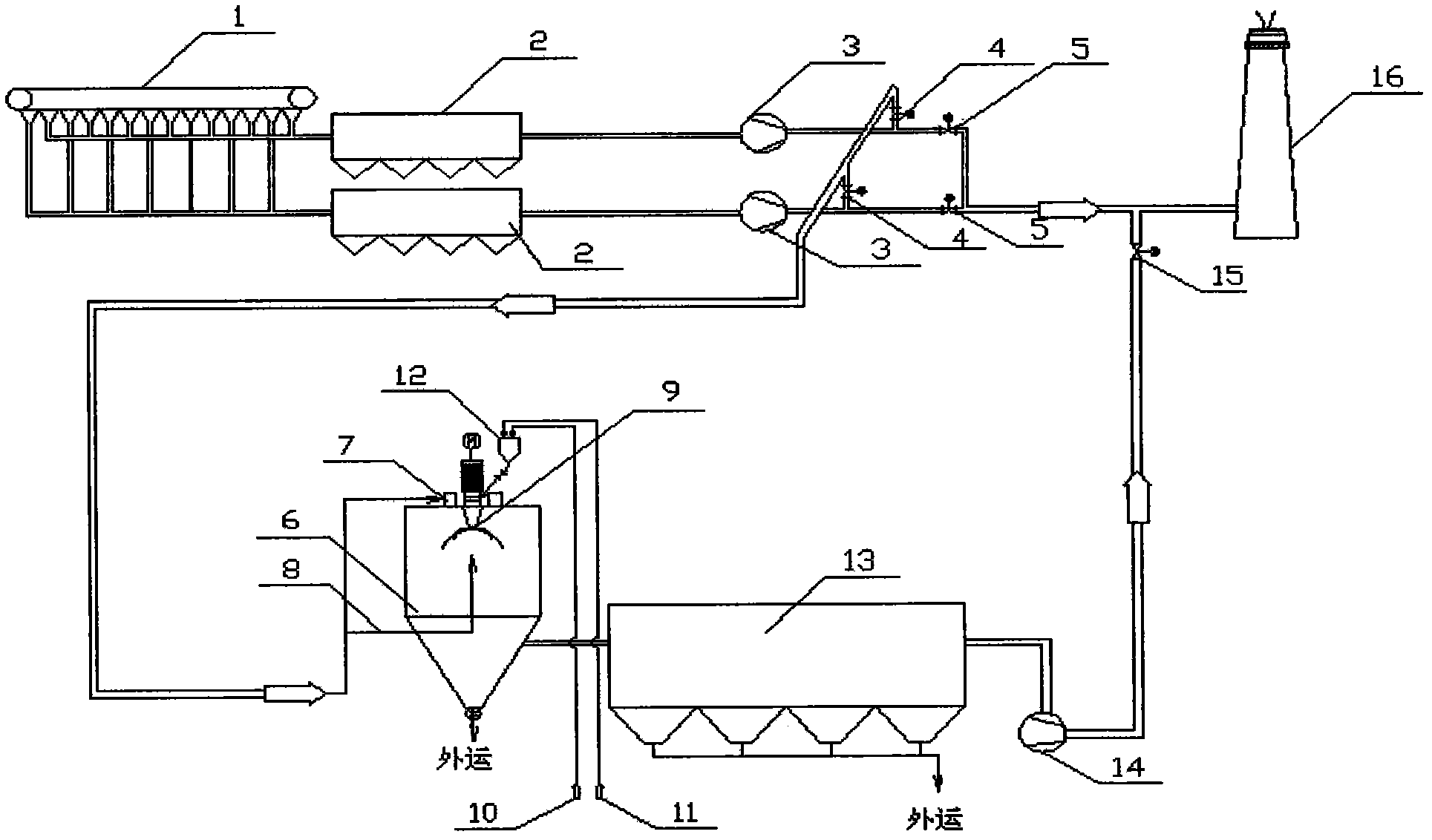

[0050] Such as figure 2 As shown, the process flow of the present invention is: sintering flue gas-electrostatic precipitator-main exhaust fan-desulfurization tower-pulse bag filter-booster fan-chimney-external exhaust. Specifically: the flue gas from the head of the sintering machine 1 is purified by the electrostatic precipitator 2, and is led out by the outlet flue of the main exhaust fan 3, and sent into the flue gas bypass flap valve 5 and the inlet flap valve 4 after switching Rotating spray desulfurization tower 6, the sintering flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com