Oven of coating machine

A technology of coating machine and oven, which is applied to the device for coating liquid on the surface, coating, and pretreatment of the surface, etc. It can solve the problems of high air pressure in the drying chamber, deformation of the box, and large air volume, so as to ensure the baking The effect of increasing the quality, increasing the transmission speed, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and in combination with preferred specific embodiments.

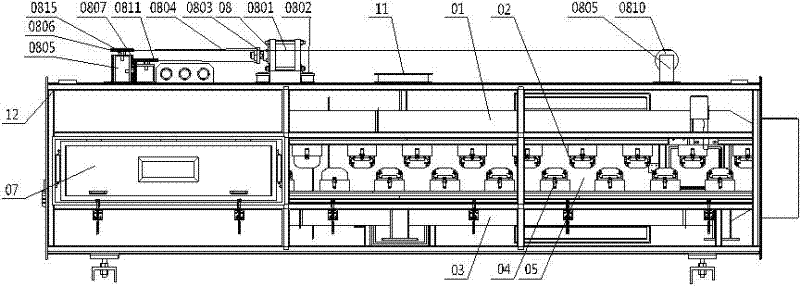

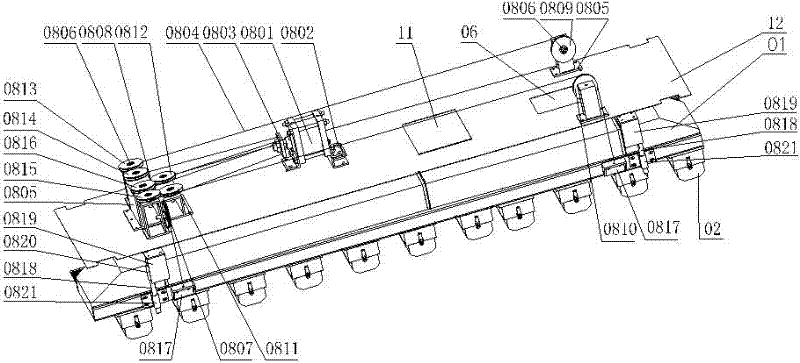

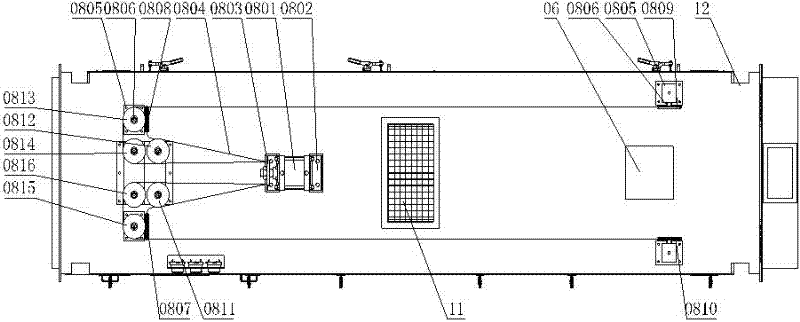

[0021] See attached figure 1 to attach Figure 5 :

[0022] A coater oven, comprising an auxiliary oven at the feed end, an auxiliary oven at the discharge end, and a main oven between the auxiliary oven at the feed end and the auxiliary oven at the discharge end; wherein, the auxiliary oven at the feed end and the auxiliary oven at the discharge end The auxiliary ovens at the discharge end are floating roller-supported ovens, and the main oven is a suspension oven. Both the auxiliary oven at the feed end and the auxiliary oven at the discharge end are arc-shaped, and the main oven is set horizontally.

[0023] The suspension oven includes a heating device, an upper static pressure chamber 01, an upper air nozzle 02, a lower static pressure chamber 03, a lower air nozzle 04, a drying chamber 05, an exhaust outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com