Copper-based alloy for cable shielding

A copper-based alloy and cable shielding technology, which is applied to power cables with shielding layers/conductive layers, etc., can solve the problems of poor performance stability and low strength of cable shielding tapes, and achieve improved welding performance and oxidation resistance, and tensile strength Effects of increased strength and hardness, and increased recrystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

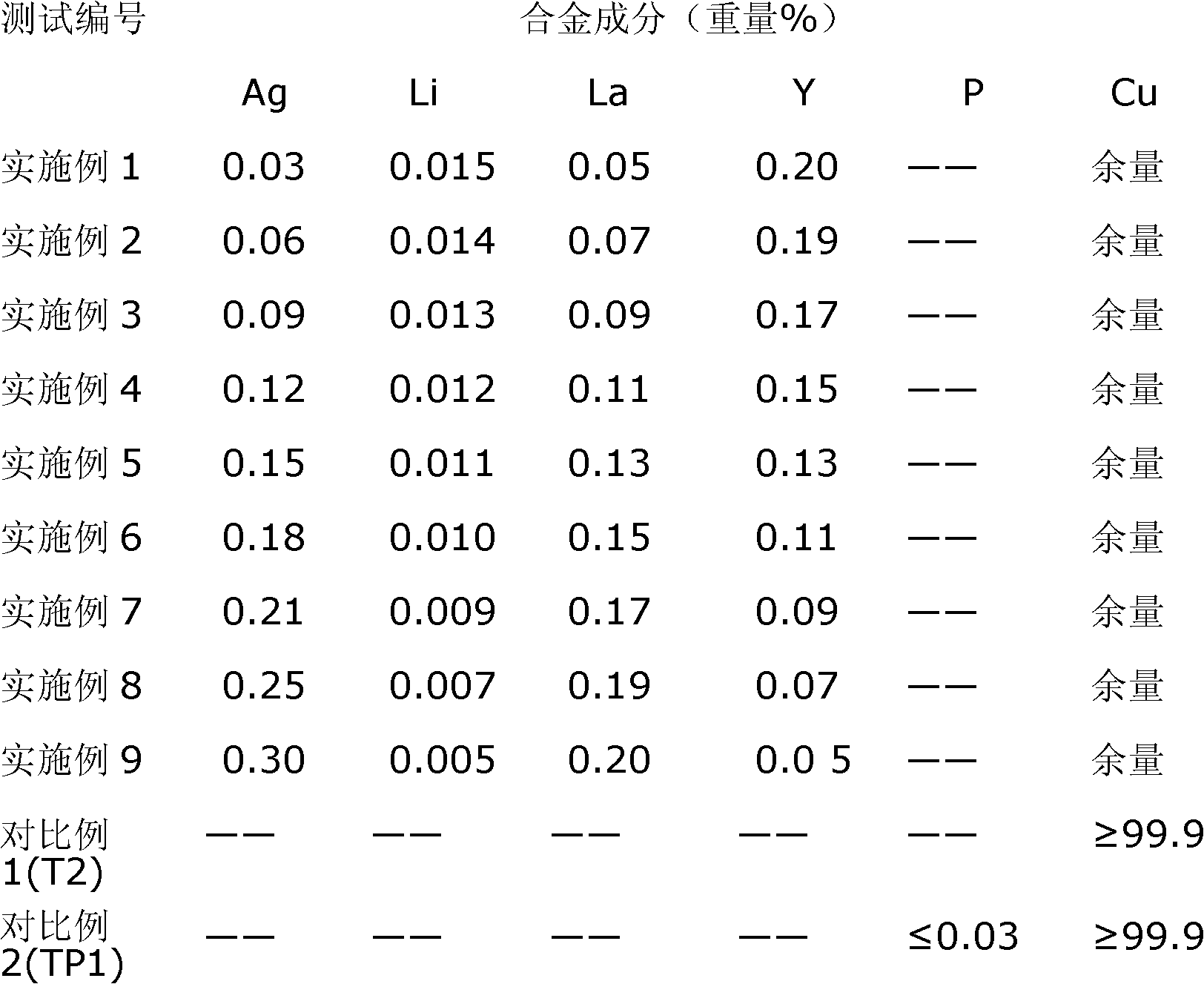

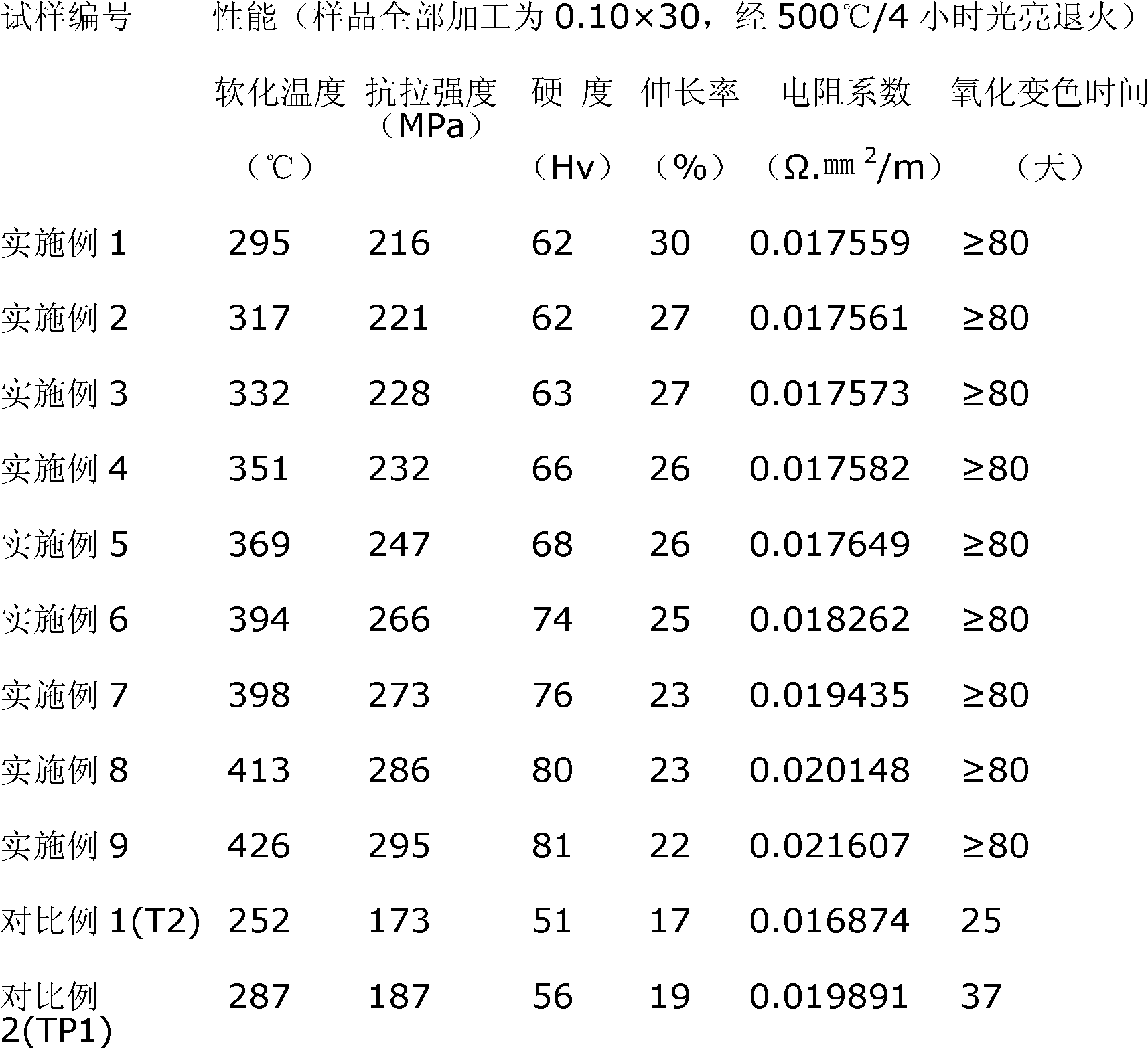

[0016] The present invention will be further described below by embodiment. According to the composition shown in Table 1, melt copper in an intermediate frequency induction furnace, add Ag for refining, adjust the temperature to the casting temperature, add the prepared CuLi, CuLa, CuY alloys, stir evenly, cast billets, and perform conventional processing according to the pure copper processing technology Processing, making samples, measuring its recrystallization temperature, tensile strength and hardness, and carrying out welding performance and oxidation resistance tests. The results are compared with the national standard brand products T2 and TP1, which are widely used now. The results are listed in Table 2.

[0017] It can be seen from the results in Table 2 that the electrical conductivity of the copper-based alloy of the present invention is close to that of the prior art, but its comprehensive mechanical properties and oxidation resistance are significantly better tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com