Multi-head gripper for full-sleeve full-rotation drill

A technology of full rotary drilling rig and full casing, applied in rotary drilling rig, casing, rotary drilling and other directions, can solve the problems of poor neutrality, casing crushing digging force, affecting construction progress, etc., and achieve good bearing lubrication , the method is simple and reliable, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

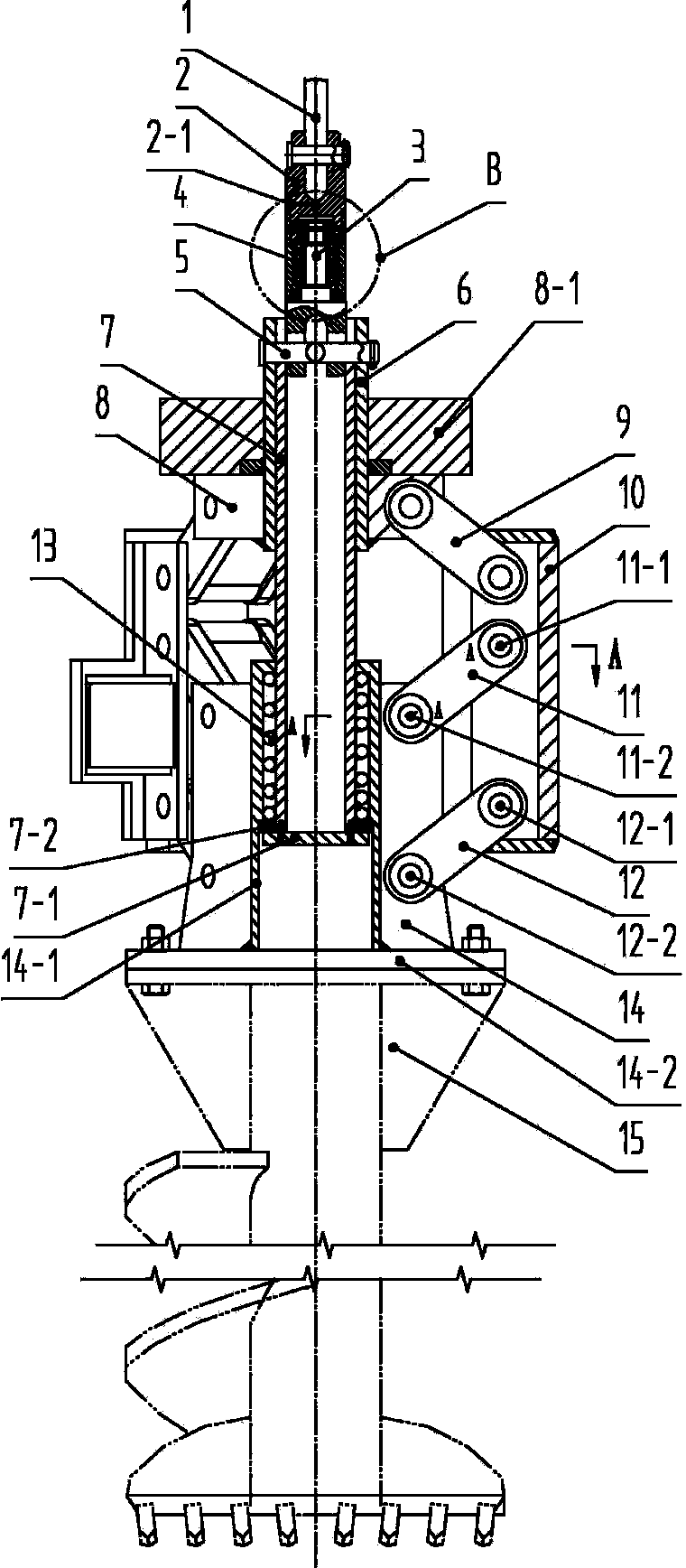

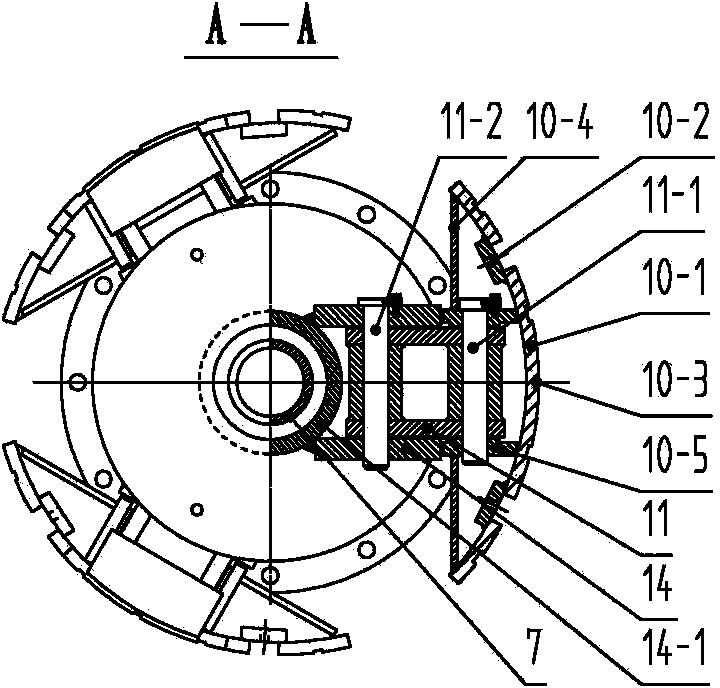

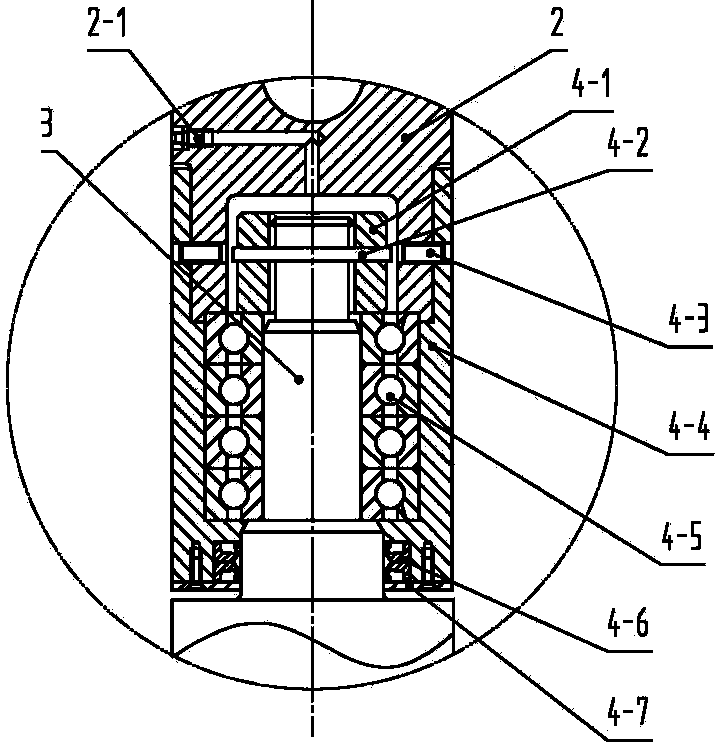

[0023] as attached figure 1 , 2 , 3 shows: a multi-head gripper for full-casing full-rotation drilling rig, characterized in that it includes: wire rope joint 2, rotary connection assembly 4, mandrel 3, connection sleeve 7, upper connection device 8, lower connection device 14 and brake shoe assembly 10; the upper end of the wire rope joint 2 is connected to the hoisting device on the full-turn drilling rig through the wire rope 1, and the lower end of the wire rope joint 2 is connected to the connection sleeve 7 through the rotary connection assembly 4; the outer sleeve 6 is set on the connection On the sleeve 7, the two are fixed by the pin shaft III5; the upper connecting device 8 is fixed on the outer casing 6; the lower end of the connecting sleeve 7 is connected with the lower connecting device 14; the brake shoe assembly 10 is Three groups, the upper end of which is connected to the upper connection device 8 through the drive rod 9, the middle and lower part of the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com