High performance nanometer semiconductive nylon belt, conductive solution and technology for manufacturing the nylon belt

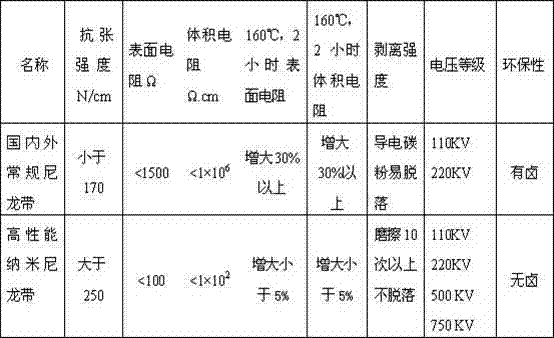

A semi-conductive, high-performance technology, applied in the field of conductive liquid, can solve the problems affecting the electrical conductivity of nylon tape, low tensile strength, surface resistance, and large volume resistance, etc., to achieve superior semi-conductive performance, stable electrical conductivity, and tensile strength strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

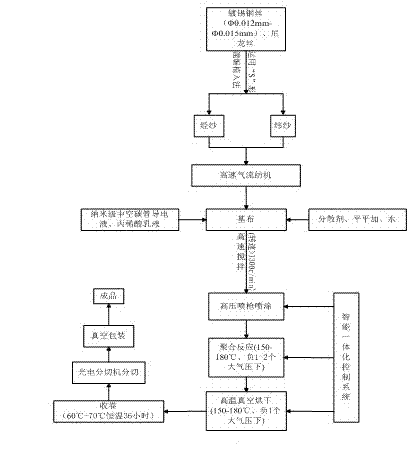

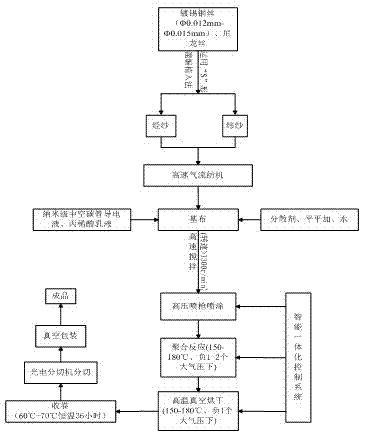

[0024] The present invention carries out according to the following steps:

[0025] 1) On the basis of ordinary nylon fabric and nylon and polyester blended fabric, the content of tinned copper wire in the original warp structure is increased, that is, tinned copper wire and polyester filament or nylon wire are twisted and twisted to make warp yarn. Then the warp and weft yarns are woven into nylon cloth of required density;

[0026] 2) Preparation of conductive liquid: replace ordinary conductive carbon black with halogen-free nano-scale conductive hollow carbon tube components, and then stir with acrylic acid emulsion, dispersant, Pingpingjia, and water at high speed. The mass percentage of conductive liquid components is as follows:

[0027] Halogen-free nanoscale conductive hollow carbon tubes: 20%;

[0028] Acrylic emulsion: 20%;

[0029] Dispersant: 5%;

[0030] Pingping plus: 5%;

[0031] Water: 50%;

[0032] 3) Using the German intelligent GHP high-pressure spray ...

Embodiment 2

[0041] The present invention carries out according to the following steps:

[0042] 1) On the basis of ordinary nylon fabric and nylon and polyester blended fabric, the content of tinned copper wire in the original warp structure is increased, that is, tinned copper wire and polyester filament or nylon wire are twisted and twisted to make warp yarn. Then the warp and weft yarns are woven into nylon cloth of required density;

[0043] 2) Preparation of conductive liquid: replace ordinary conductive carbon black with halogen-free nano-scale conductive hollow carbon tube components, and then stir with acrylic acid emulsion, dispersant, Pingpingjia, and water at high speed. The mass percentage of conductive liquid components is as follows:

[0044] Halogen-free nanoscale conductive hollow carbon tubes: 30%;

[0045] Acrylic emulsion: 10%;

[0046] Dispersant: 4%;

[0047] Pingping plus: 4%;

[0048] Water: 48%;

[0049] 3) Using the German intelligent GHP high-pressure spray ...

Embodiment 3

[0058] The present invention carries out according to the following steps:

[0059] 1) On the basis of ordinary nylon fabric and nylon and polyester blended fabric, the content of tinned copper wire in the original warp structure is increased, that is, tinned copper wire and polyester filament or nylon wire are twisted and twisted to make warp yarn. Then the warp and weft yarns are woven into nylon cloth of required density;

[0060] 2) Preparation of conductive liquid: replace ordinary conductive carbon black with halogen-free nano-scale conductive hollow carbon tube components, and then stir with acrylic acid emulsion, dispersant, Pingpingjia, and water at high speed. The mass percentage of conductive liquid components is as follows:

[0061] Halogen-free nanoscale conductive hollow carbon tubes: 29%;

[0062] Acrylic emulsion: 18%;

[0063] Dispersant: 4%;

[0064] Pingping plus: 3%;

[0065] Water: 46%;

[0066] 3) Using the German intelligent GHP high-pressure spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com