Overhead silane self-crosslinking bi-component internal shielding material and preparation method thereof

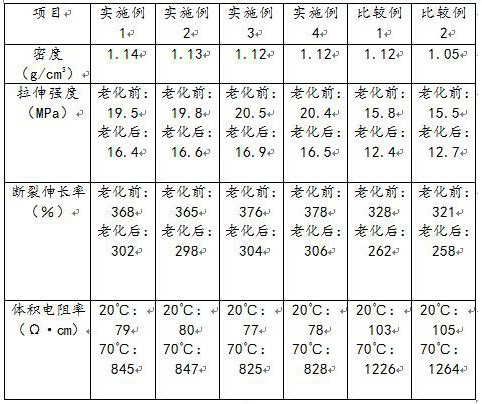

A self-crosslinking, two-component technology, applied in the field of overhead cables, can solve the problems of large change rate of tensile strength and elongation at break, poor heat resistance and weather resistance, poor flame retardancy, and poor performance of finished products , to achieve the effects of small change rate of tensile strength and elongation at break, obvious elongation at break, high practicability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] like figure 1 As shown, an overhead silane self-crosslinking two-component inner shielding material proposed by an embodiment of the present invention includes A-component material and B-component material, and A-component material includes the following components by weight: ethylene-vinyl alcohol 35 parts of copolymer, 28 parts of ethylene-vinyl acetate copolymer, 20 parts of conductive carbon black, 10 parts of titanium dioxide, 2 parts of silane coupling agent KH550, 2 parts of antioxidant 1010, 1 part of magnesium hydroxide, azodiiso 1 part of nitrile, 1 part of polyethylene wax; component B includes the following components in parts by weight: 97 parts of ethylene-vinyl alcohol copolymer, 2 parts of dibutyltin dilaurate, and 1 part of antioxidant 168.

[0028] The present invention also provides a method for preparing an overhead silane self-crosslinking two-component inner shielding material, comprising the following steps:

[0029] S1, by weight, ethylene-vinyl...

Embodiment 2

[0034] like figure 1 As shown, an overhead silane self-crosslinking two-component inner shielding material proposed by an embodiment of the present invention includes A-component material and B-component material, and A-component material includes the following components by weight: ethylene-vinyl alcohol 48 parts of copolymer, 26 parts of ethylene-vinyl acetate copolymer, 15 parts of conductive carbon black, 8 parts of titanium dioxide, 1 part of silane coupling agent KH560, 0.5 part of antioxidant BHT, 0.5 part of zinc borate, azobis 0.5 part of isoheptyl nitrile, 0.5 part of EVA wax; component B includes the following components in parts by weight: 99 parts of ethylene-vinyl alcohol copolymer, 0.5 part of dioctyltin dilaurate, and 0.5 part of antioxidant 1010.

[0035] The present invention also provides a method for preparing an overhead silane self-crosslinking two-component inner shielding material, comprising the following steps:

[0036] S1. In parts by weight, ethyle...

Embodiment 3

[0041] like figure 1 As shown, an overhead silane self-crosslinking two-component inner shielding material proposed by an embodiment of the present invention includes A-component material and B-component material, and A-component material includes the following components by weight: ethylene-vinyl alcohol 40 parts of copolymer, 27 parts of ethylene-vinyl acetate copolymer, 17 parts of conductive carbon black, 9 parts of titanium dioxide, 2 parts of silane coupling agent KH570, 2 parts of antioxidant 1098, 1 part of ammonium polyphosphate, peroxide 1 part of hydrogen, 1 part of white oil; component B includes the following components in parts by weight: 98 parts of ethylene-vinyl alcohol copolymer, 1 part of stannous octoate, and 1 part of antioxidant 300.

[0042] The present invention also provides a method for preparing an overhead silane self-crosslinking two-component inner shielding material, comprising the following steps:

[0043] S1, by weight, ethylene-vinyl alcohol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com