A kind of halogen-free high temperature resistant conductor shielding material and preparation method thereof

A technology for conductor shielding and high temperature resistance, applied in the field of halogen-free and high temperature resistant conductor shielding materials and their preparation, can solve the problems of poor processing performance and high temperature resistance, damage to conductors and insulating materials, and threat to life and safety, and achieve high tensile strength. , the effect of excellent semiconductive properties and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

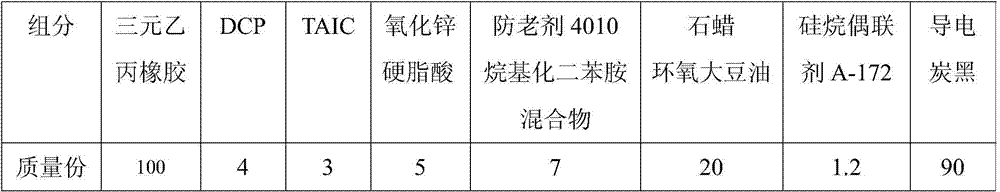

[0027] Carry out the preparation of the halogen-free high temperature resistant conductor shielding material of the present invention according to the following component formula:

[0028] Formulation of each component of shielding material in embodiment 1 of table 1

[0029]

[0030] According to the formulation of each component in Table 1, the halogen-free high temperature resistant conductor shielding material of the present invention is prepared, and its specific preparation method is as follows:

[0031] A. Weighing: Weigh the raw materials according to the formula components and parts by mass in Table 1, and set aside;

[0032] B. Mixing: first put the EPDM rubber into the internal mixer and masticate for 6 minutes, then add anti-aging agent 4010, alkylated diphenylamine mixture, zinc oxide, stearic acid, conductive carbon black, paraffin, and ring Oxygenated soybean oil and silane coupling agent A-172 were mixed for 4 minutes, then dicumyl oxide (DCP) and triallyl ...

Embodiment 2

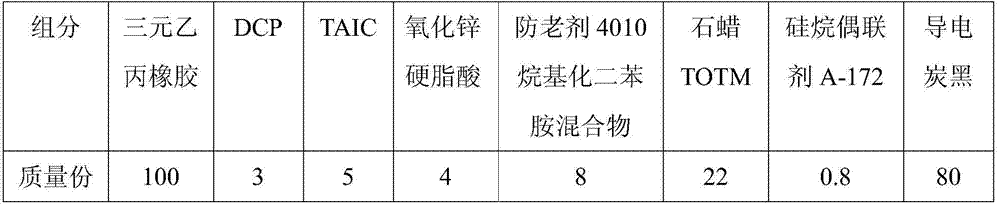

[0037] Carry out the preparation of the halogen-free high temperature resistant conductor shielding material of the present invention according to the following component formula:

[0038] Formulation of each component of shielding material of table 2 embodiment 2

[0039]

[0040] According to the formulation of each component in Table 2, the halogen-free high temperature resistant conductor shielding material of the present invention is prepared, and its specific preparation method is as follows:

[0041] A. Weighing: Weigh the raw materials according to the formula components and parts by mass in Table 2, and set aside;

[0042] B. Mixing: first put EPDM rubber into the mixer for 8 minutes, then add anti-aging agent 4010, alkylated diphenylamine mixture, zinc oxide, stearic acid, conductive carbon black, paraffin, partial Trioctyl trimellitate (TOTM) and silane coupling agent A-172 were mixed for 3 minutes, then dicumyl oxide (DCP) and triallyl isocyanurate (TAIC) were ...

Embodiment 3

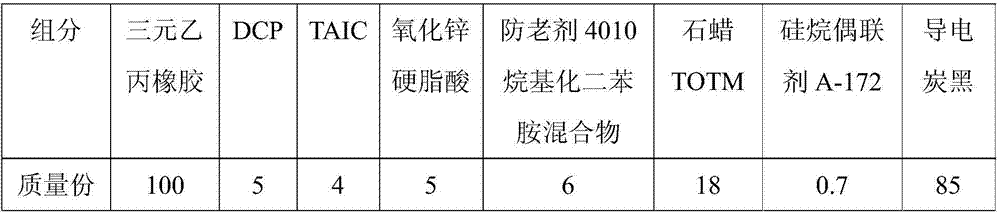

[0047] Carry out the preparation of the halogen-free high temperature resistant conductor shielding material of the present invention according to the following component formula:

[0048] Table 3 Example 3 The formula of each component of the shielding material

[0049]

[0050] According to the formulation of each component in Table 2, the halogen-free high temperature resistant conductor shielding material of the present invention is prepared, and its specific preparation method is as follows:

[0051] A. Weighing: Take the raw materials according to the formula components and parts by mass in Table 3, and set aside;

[0052] B. Mixing: first put the EPDM rubber into the internal mixer and masticate for 10 minutes, then add anti-aging agent 4010, alkylated diphenylamine mixture, zinc oxide, stearic acid, conductive carbon black, paraffin, partial Trioctyl trimellitate (TOTM) and silane coupling agent A-172 and mixed for 5 minutes, then added dicumyl oxide (DCP) and triall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com