Electrode material, method for producing same, and lithium ion secondary battery

An electrode material and secondary battery technology, applied in electrode manufacturing, secondary batteries, lithium storage batteries, etc., can solve problems such as difficulty in thinking, unclear plasma method, etc., and achieve the effect of low internal resistance

Active Publication Date: 2012-03-21

NAMICS CORPORATION

View PDF9 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, as shown in the description of paragraph [0011], CVD or PVD is described as a problematic existing method, so it is difficult to consider the method such as the atmospheric pressure plasma as plasma CVD, and it is not clear how to specifically use the plasma. clear

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0116] Hereinafter, the present invention will be described in detail using examples, but the present invention is not limited to these examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

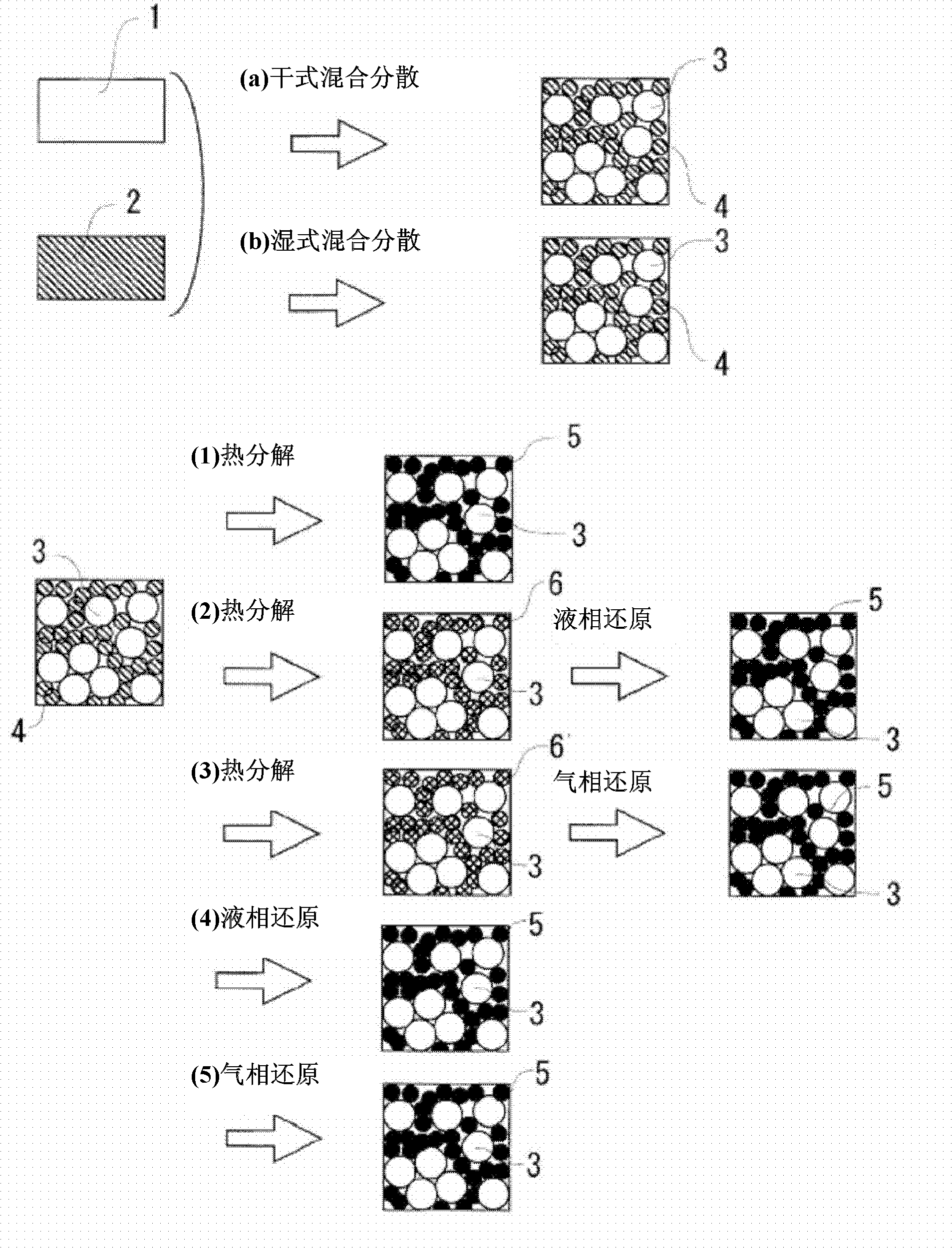

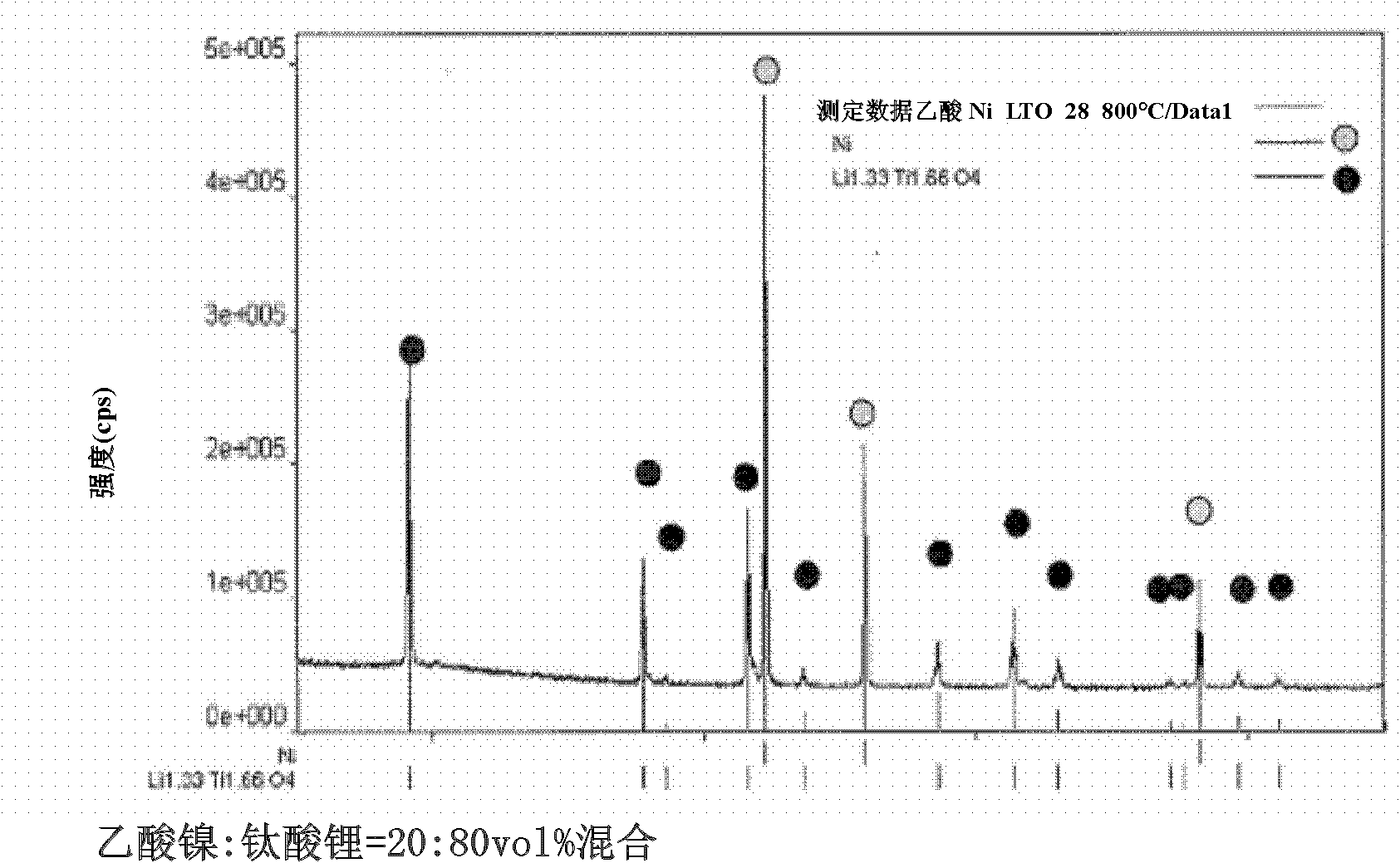

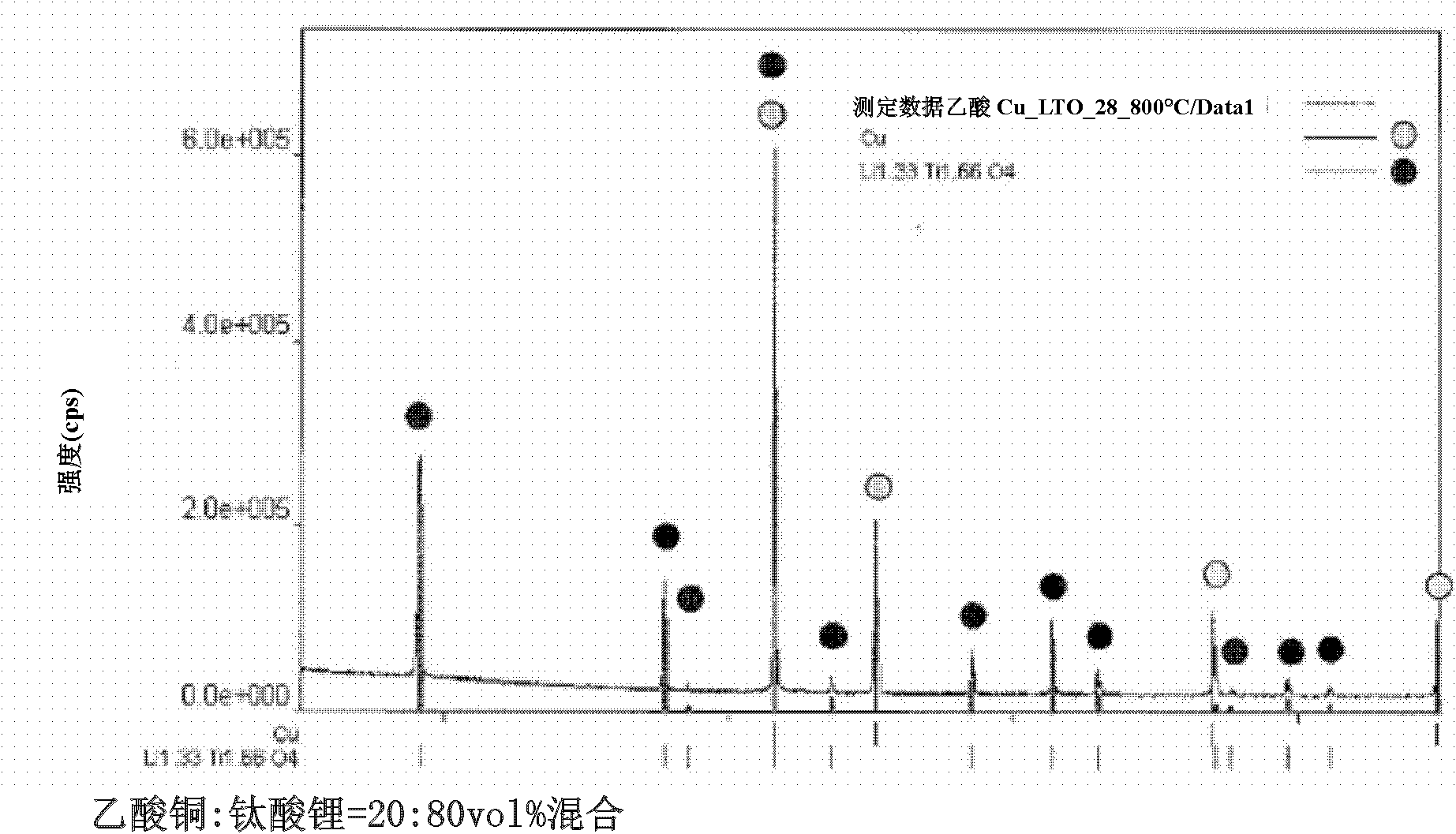

Secondary batteries for automobiles require good input / output characteristics and low internal resistance. Although there is a conventional technique wherein the surface of an active material is coated with metal particles for the purpose of reducing the internal resistance of a battery, the technique cannot achieve remarkable effects on improvement in the conductivity of the active material or decrease in the internal resistance of the battery since an oxide film is formed on the metal particle surfaces. Disclosed is an electrode material which is produced by mixing and dispersing an active material and a metal source compound, and then depositing metal particles on the surface of the active material by thermal decomposition, vapor phase reduction, liquid phase reduction or a chemical reaction combining any of the thermal decomposition, vapor phase reduction and liquid phase reduction. Since an oxide film is not formed on the metal particles, an electrode material having high conductivity can be obtained. The electrode material can have significant effects on decrease in the internal resistance of a battery and improvement in the input / output characteristics of a battery.

Description

technical field [0001] The present invention relates to an electrode material and a manufacturing method thereof, in particular to an electrode material suitable for a lithium ion secondary battery and a manufacturing method thereof. Background technique [0002] In recent years, the development of hybrid vehicles has been progressing as an environment-friendly vehicle. On the other hand, the non-aqueous lithium ion secondary battery has the characteristics of being able to obtain a high voltage exceeding the electrolysis voltage of water and having a high energy density. Because of such characteristics, utilization of lithium ion secondary batteries in hybrid vehicles has been studied. However, conventional lithium ion secondary batteries have a disadvantage of high internal resistance because active materials constituting electrodes have low conductivity. As an attempt to reduce the internal resistance of a lithium ion secondary battery, a method of mixing a conductive a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/13H01M4/139H01M4/36H01M10/052

CPCH01M4/1391H01M4/485H01M4/624H01M4/131Y02E60/122H01M4/0421Y02T10/7011H01M4/0428H01M4/0471H01M4/626H01M10/0525H01M10/0562Y02E60/10H01M4/139H01M4/36H01M10/052Y02T10/70

Inventor 佐藤洋藤田隆幸

Owner NAMICS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com