Single-component epoxy resin conductive adhesive

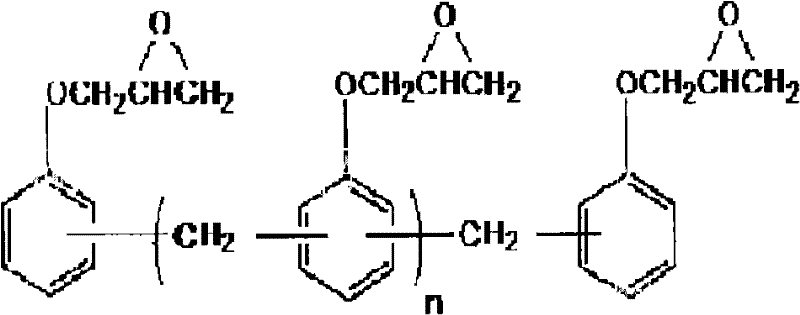

An epoxy resin and adhesive technology, applied in epoxy resin adhesive, novolac epoxy resin adhesive, conductive adhesive, etc., can solve the problem of poor heat resistance, low glass transition temperature, unfavorable conductive adhesive treatment or application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

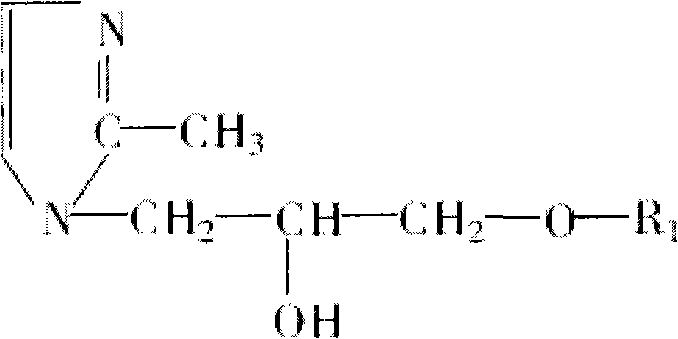

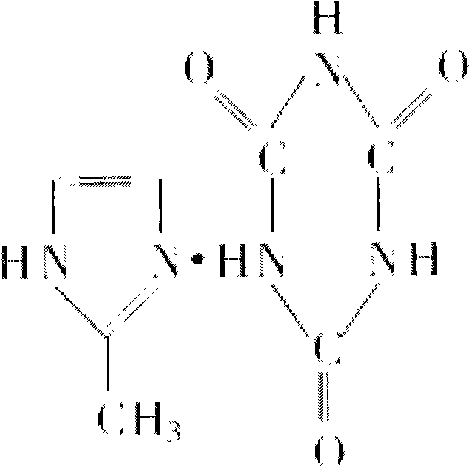

Method used

Image

Examples

Embodiment 1

[0043] First heat and mix various resin parts, namely 7g epoxy resin E-51, 5g toughening agent EPICLON750, 6g curing agent phenol novolac resin, then add 1g accelerator EH3293S, 73g conductive filler silver powder, and 8g solvent ethylene glycol ether , ball milling, natural degassing during the mixing process, and airtight mixing.

Embodiment 2

[0045] First heat and mix various resin parts, namely 10g epoxy resin EPICLON850-CRP, 3g toughening agent CTBN, 8g curing agent dicyandiamide, then add 1g accelerator PN-23, 72g conductive filler silver powder, and 6g solvent ethyl acetate , ball milling, natural degassing during the mixing process, and airtight mixing.

Embodiment 3

[0047] First heat and mix various resin parts, that is, 10g epoxy resin E-51, 5g toughening agent EPICLON750, 8g curing agent phenol novolac resin, then add 2g accelerator MY-24, 70g conductive filler copper powder, and 5g solvent pine Oleyl alcohol, mixed by ball milling, natural degassing during the mixing process, and airtight mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com