Technology for treating cold aluminous ash by utilization of tilting furnace

A treatment process and rotary furnace technology, applied in the field of aluminum alloy processing, can solve the problems that slag presses or ash mixers are difficult to adapt to large-scale production, cannot adapt to large-scale production, and cannot handle cold ash slag, so as to improve interfacial tension and production Powerful, easy-to-separate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

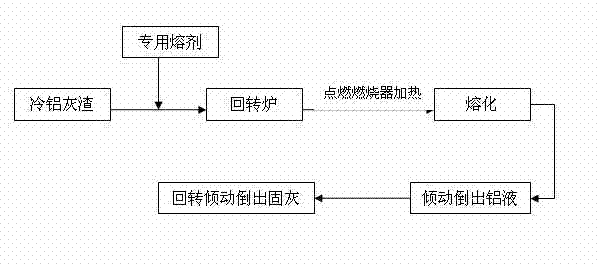

[0016] When using the present invention to process cold aluminum ash, first add 10% of the total amount of special flux into the rotary kiln. The special flux is composed of 95% mixed chloride and 5% fluoride industrial salt. Re-ignite the burner to start heating, and rotate the furnace body at the same time. After the flux is melted, add cold aluminum ash coarse particles accounting for 90% of the total amount, and heat for a certain period of time while rotating the furnace body. The aluminum alloy liquid and ash are separated. , the aluminum alloy liquid is enriched in the lower part, and the ash slag floats on the surface of the aluminum liquid. At this time, stop the rotation and heating, first tilt the furnace body to pour out the molten aluminum, and then pour out the solid ash while turning the furnace body, completing an operation cycle.

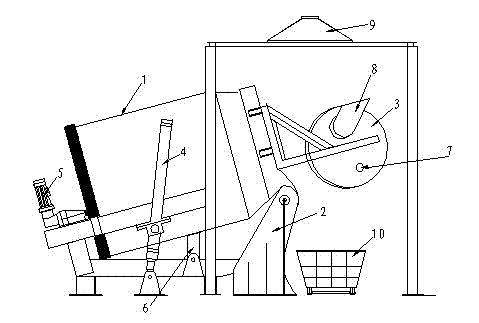

[0017] The rotary kiln as figure 2 As shown, it includes a furnace cylinder body 1, a movable support 2, a furnace cover 3 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com